The blender is a motor equipped with an attachment. Nothing complicated. The bowl with the knife is placed on the output shaft of the electric motor, and the engine lock is switched off. The assembled device is started by the power button in cruising or pulse mode. The process is helped by a speed regulator, a cord with a plug, and less often a fuse. It is not difficult to disassemble the blender, the main thing is to reassemble it later. Can you handle it? Those who doubt it, read on to learn how to repair a blender with your own hands. We recommend avoiding jumping through sections.

How does a blender work?

Nature has created three types of blenders:

- Stationary.

- Manual (submersible).

- Complementary composition of the food processor.

The blender design in each case provides for the presence of an electric motor - the initial driving force; the principle of operation changes according to the tasks performed. Stationary blenders are reminiscent of replenishing combines. You will see two characteristic prefabricated units that help the device perform its duties:

- Engine.

- Bowl with knife.

Do-it-yourself repair or call a professional?

Under conditions of proper use of the blender, an early breakdown is very rare. Most often, unforeseen situations arise when equipment is used incorrectly: when connected to an unreliable power strip or faulty socket, when the voltage in the power supply is unstable or for long periods of non-stop operation. In such situations, the electronic component of the device initially suffers - boards, relays and wires burn out and become unusable. Replacing parts requires certain qualifications, knowledge and experience, so it is better to show a broken blender to a specialist. SMEG provides a warranty on all kitchen appliances. The service center technicians will diagnose the device and, if a problem is found, they will effectively fix it.

Stationary blender

Let's talk about how the product works. The knife rotates quickly in the bowl, where the chopped products are placed. A specific blade causes the contents to move along a closed path. The knife is located at the bottom. When the electric motor transmits torque to the blade through the output shaft and spindle, the blade's revolutions quickly increase. Due to the speed (thousands of revolutions every minute), the effect of movement of the crushed mass is obtained. The envelope of the blender blade resembles a propeller. The cross pulls fruits and vegetables on top of itself, and throws crushed pieces to the sides.

Then the profile of the bowl comes into play, twisting the movement of the food mass. The walls expand upward, so under the pressure of the flow coming out of the knife, the mash begins to creep upward. In the center, pieces of food fall down. The processed mass reaches the lid and falls back onto the knives. The described process proceeds at a speed beyond the grasp of the eye.

The considered cycle occurs ideally in strong blenders. Cheap household models do not have enough revolutions to establish closed motion. The knife cuts the void. Therefore, wanting to chop the cabbage, the cook is forced to add water. The step releases the laws of hydrodynamics, which come into play, making the work of the knives easier. So first! Before fixing the blender (which may not have broken):

- If a low-power blender does not want to grind the mass, the fact does not indicate a 100% malfunction. Try adding water, milk, juice, and repeat the process.

- A simple fact means: the blade of the blender is dull, the speed switch is broken, the engine lacks the necessary power. The masters say: the problem affects the bowl. More precisely, it lies in the rotating joint of the knife.

In our case, it is recommended to start with a speed test. There are simply up to ten positions of the regulator, you need to go through fixed places one by one, assessing by ear whether the blender blade is moving faster or slower.

How to disassemble and repair a blender depending on the cause of the breakdown - minor faults

It is immediately necessary to note the fact that not all devices are capable of grinding food equally well. For example, low-power models are not able to cope with solid food, so if your blender does not work, or rather does not cut food, this does not mean that it is broken and needs repair. If, after turning on, the device starts to buzz, but no process occurs, you need to check two things:

- whether the knives rotate if they are not obstructed by food. If yes, then this means that your device is simply not capable of handling such a volume, and it does not need repair. To do this, you need to either add liquid or reduce the amount of grinding;

- in some cases it may not cut due to dull knives.

In the first case, you will not do anything, since your model is of very low power. But we will describe below how to replace the knife.

Check the blender before disassembling!

Replacing the blender blade

As for the blender knife, it is unlikely that you will be able to sharpen the blade at home by hand. Buy a new one, there are 3 scenarios waiting for you:

- Firstly, the knife is sold as a separate spare part. In this case, remove the old one. An old, clean towel will help. Wrap a rag around the blender blade and unscrew it from the spindle. Please note: the thread is left-handed, so you need to twist it in the opposite direction than traditionally. It happens that the knife is mounted using several nuts. A wrench and pliers will help you remove the accessory from the blender. The bowl has been removed from the output shaft, the plug has left the socket. The rotating blade of the blender can easily disfigure your fingers, and it will be difficult for doctors to put them back together. It happens that the knife is sold together with the oil seal, change both parts.

- It happens that to dismantle the knife, it is necessary to disassemble the blender bowl. A rare case. Replacement takes place using the described method; take the trouble to update the oil seal covering the spindle.

- Finally, it was discovered that the bowl was not removable. See how to proceed. For such blenders, you will have to change the bowl along with the knife and seal.

Features of disassembly from different manufacturers

When disassembling the device, you need to take into account the design features. Equipment from different manufacturers has distinctive features.

"Brown"

The main feature of Braun blenders is that during disassembly the engine is removed along with the control system. If this does not happen, you need to pull the edge of the board with pliers.

"Philips"

In Philips devices, there is a cover on the back end, under which there are 2 screws for the power cord. They hold the engine and do not allow it to be removed from the other side.

"Bosch"

To disassemble Bosch devices, just use a screwdriver. Having lifted the case and removed the latches, all that remains is to unscrew the screws to gain access to the mechanisms.

"Kenwood"

The process of disassembling Kenwood blenders is similar to unwinding Bosch appliances. Using a screwdriver, you need to break through the gluing area and walk along the entire casing. Then disassembly is continued from the reverse side, prying the regulator handle in several places.

Polaris

When disassembling devices from, you need to unscrew all visible screws. After removing the fastening, it is possible to separate the parts of the housing and gain access to the internal structure.

Vitek

The halves of the Vitek blender body are secured with latches. The main retaining screw is located under the switch, which can be removed by prying with a screwdriver.

Blender speed controller

Frequent problems with blenders are related to the speed switch. Only a master can fully check the functionality. If you have the knowledge of a radio technician, try ringing the part first. Surely it will be immediately clear whether this is the reason for the strange behavior of the blender. The switch is removed from the device (soldered off), and the positions are checked in full. Naturally, during normal operation, the contacts must alternately produce a short circuit, switching the corresponding windings of the electrical heart of the device.

At the same time, try the method described above. Turn on the device, listen to how the engine behaves while working at fixed speeds. There is a pattern: the blender blade moves faster, the buzzing is stronger. Advanced models have a lock against turning on without a bowl.

Note that the safety part was introduced in the 20s of the twentieth century, when the blender was just invented. The patent applicant emphasized: the engine starts when the bowl is installed. Therefore, we consider the option to be fully classic.

The locking mechanism is the reason why the blender has stopped. What else are they doing...

Conclusion

If the blender breaks down for any reason, you do not need to immediately contact the specialists. After all, the cause could be a simple cable breakdown or blocking of the knives. Before wondering if the blender is not working, what should you do? Check the elementary possible causes and only after that, evaluate your strengths and capabilities, and only then proceed with independent repairs.

I would also like to say that some spare parts for these household appliances are very expensive. In addition, manufactured non-original spare parts do not guarantee long and high-quality operation. Therefore, before you start repairing it yourself or in a workshop, evaluate its feasibility. Because sometimes the difference between a repair and a new device can be only a few hundred rubles.

If the blender stops

It happened that the device refuses to work. The situation is resolved more easily than in the case when the blender is too lazy to cut and does not chop.

First, we strain our ears by turning on the device. If a buzzing sound is discernible, then the problem is probably a jammed knife. Remove the bowl and gently press the power lock button with your finger (pencil, pin). It worked - the matter is limited to a bowl, a knife. They told me how to fix the problem. The atypical case is much more interesting: a buzzing sound is heard, the blender stiffens even with the lock released. Surely the cause is the motor - the winding burned out. Here the result is determined by the price of the issue; if there is a way to get a new engine at a reasonable price, it is worth replacing. Cheap models make you throw away the idea of fixing a blender yourself.

When no buzzing sound is detected with the button turned on, we examine the power supply path:

- First of all, check the presence of voltage at the outlet. Practice shows that most problems are resolved at this stage. A blender, like other household appliances, breaks down relatively rarely. Plug in a known working table lamp or something stronger. If it works properly, we move on to the second procedure.

- To check the cord, we disassemble the blender body. We turn off the device from the network, take a screwdriver. Rare foreign models will require special heads. Throw away the cross and slotted screwdriver. Inside the blender there is a power block carrying a soldered or screwed cord. We check the voltage with a voltmeter, or take a known-good cord, connect it, and try the assembly. The location of the breakdown is localized. In some severe cases, the voltage cannot be measured. Less suitable contacts are covered with plastic and are not removable. Those who avoid cutting the device take a needle and solder a wire to the tip. You will need two homemade gizmos. We turn off the blender from the network, pierce both wires of the cable with needles, and connect the tester terminals. We make sure that the lines do not overlap each other, keep our hands off, and plug into the network. We look at the result on the tester display.

- The above actions are simplified if a fuse is inserted into the blender. We take it out and call. The breakdown is identified - we visit the store and purchase a new one. Parameters (power, current) are inscribed on the glass (ceramic) case. We use numbers when choosing the right product in the store. Avoid attempts to make a makeshift fuse; a rash step will most likely cause a fire. A new one is inexpensive. In the open circuit, measure the supplied voltage with a tester (multimeter). When there is nowhere else to measure the mains voltage (230 volts), the fuse slot will do.

- It happens that the new fuse instantly fails. There is a short circuit inside the blender. The problem affects the integrity of the motor windings and electronic circuits. We try to connect energy consumers one by one to the source, and observe the result. Experts recommend using a homemade bug that can withstand the resulting electric current. We connect a multimeter and measure the amperes. The operation is done extremely quickly, otherwise there is a chance that traffic jams will break out at home. We use the measured value to calculate the power. If the figure obviously exceeds that indicated in the passport, the faulty unit has been found. As mentioned above, problem blocks: blender motor, circuit boards.

- If the described operations lead to the belief that power is present, we undertake to inspect the printed circuit boards. We examine the capacitors for swelling, and the resistors for traces of burning. The tracks should not be torn or peel off from the substrate. A defect from the listed symptoms has been found - the cause of the blender malfunction is limited to the electronic filling. If the engine short circuits, the equipment cannot be restored. Winding insulation failure.

Mechanical breakdowns

A blender does not always break down due to electrical problems; often the cause of the malfunction can be ordinary mechanical damage, which can also be successfully dealt with at home.

Leaking engine gasket and bowl

If during operation of the device a leak is detected between the body and the bowl, it cannot be postponed. You need to disassemble the bowl, attachment, whisk, then remove the spindle. The gasket will be open in front of you, which is the culprit of the breakdown. To eliminate the leak, just replace it with a new one.

The latch mechanism is faulty

A blender, however, like any other equipment, can be damaged during operation, especially if it is sloppy. The latches located on the lid and additional attachments are most often subject to damage. Most often, such damage cannot be repaired, since it is very complex and short-lived. It is better to immediately contact the store to purchase attachments.

However, do not rush to throw away the damaged nozzle, since not every model has spare parts on sale.

Fastener repair

Gearbox repair

There is another weak point in modern blenders - the gearbox. Frequent breakdowns are associated with excessive load on the device. With frequent and prolonged use, it can heat up, resulting in melting of its seat and gears. This problem can be identified immediately - when you turn on the device, you will hear characteristic sounds arising from foreign objects.

To repair it yourself, you need to disassemble the device and examine it. If the internal mechanisms are intact and they just came out of the grooves, they need to be installed in place and fixed. If the gear is broken, you need to buy a new one.

Gearbox repair

Important! Select this item exactly according to size!

Hand blenders

Hand blenders often use commutator motors; motors can operate powered by direct and alternating currents. In simple models, power buttons and brush contacts are available. For spark extinguishing, capacitors are attached near the rotor. Let's say more, in addition to capacitors, varistors short-circuit voltage surges, protecting the windings against combustion. In the simplest models, thermal fuses are placed among the turns. If it burns out, the components should be replaced with new ones. The circuit is used in motors of commutator and asynchronous types, transformers. Repairing blenders with your own hands requires knowledge of the unwritten basics of electrical engineering and electronics. Let’s deal with the basics – knowledge – today.

Internal structure of hand blenders

Commutator motors are equipped with stabilization circuits, but the simplest blenders are devoid of any frills. Varistors form an important component of many devices; they protect more than just motors. In switching power supplies, high-frequency generators are switched off due to overload and the current is closed to the fuses. The result is that the protection is triggered. The fault is identified by replacing the fuse with a light bulb: on - turn off the power, continuing to troubleshoot.

The simplest commutator motor is formed by a pair of stator windings and a good bunch of rotor windings. Under the brushes there is a drum, divided into sections. Each pair of opposing contacts is equipped with a closing coil. To make sure the blender is working properly, ring each one by rotating the shaft by hand. Bearings are often considered the weak point. There are two nodes - anterior and posterior. The lion's share of the load falls on the latter. HADO is used for lubrication. After application, the composition causes the formation of a ceramic film, which temporarily improves glide while protecting the surface.

If the friction is too high, current-carrying parts may burn, blackening of the body and parts, and solder delamination. Take the trouble to remove the rotor from the bearings, wipe it with alcohol, and lubricate the parts. A brushed motor is always noisy; inertia is considered an advantage, helping to avoid speed surges. When switching the rotor windings, back EMF occurs. This is a parasitic effect, they have learned to use this phenomenon for good. Regulatory circuits of thyristors are assembled: the input voltage and the reverse voltage are added at the control electrode. The shaft load increases, the speed drops; the back EMF decreases, the thyristor opens slightly, current consumption increases, and the motor speed reaches normal.

In hand blenders, such solutions are used reluctantly, the switching element gets very hot, and there is simply nowhere to place a huge radiator. However, using simple speed adjustments will make the owner’s life much easier.

Underwater reefs identified:

- Sudden changes in voltage consumption require filtering (jumps) along the power circuit and cause sharp changes in the external network. The effect is noted when operating from a generator.

- Speed regulation is a valuable quality, but if the power increases sharply when kneading the dough, the blender will be snatched from the hands of the owner; It is more useful for calm women to buy a blender for home, which produces constant power regardless of the dish being prepared.

In advanced models, the blender device is supplemented with speeds. More often we see individual buttons that press continuously, forcing the engine to work. Done for a reason. The developers realize that a weak female hand gets tired quickly, therefore, the key will most likely be released before the engine burns out. The adjustment technique is often not particularly complex. The output voltage is removed by paired secondary windings of the transformer. There is a change in speed.

Blenders often burn if varicaps protect against power surges; thermal fuses protect the equipment against overheating. An element with a response threshold of 120 degrees is installed in the power circuit. Sometimes a thermal fuse is placed between the turns of the motor (mentioned above). The switching power supply operates according to an ordinary circuit. At the input, the voltage is filtered by capacitors, chokes, resistors, and the signal passes through a high-frequency power transistor (even two). The process is controlled by a microcircuit generator that supplies voltage to the control gate. At the output, the voltage is filtered if necessary, and less often rectified.

A frequent breakdown is winding burnout. Try to buy products equipped with fuses. Make your life incredibly simpler.

Brushed motors are controlled using a voltage cut-off circuit when a smooth transition is required. In the case of two or three fixed speeds, there is probably no need for such a scheme. The sine wave along the positive and negative half-waves is truncated to a certain area. The effective value decreases, naturally causing a decrease in the revolutions of the commutator motor shaft. As already mentioned, kitchen appliances are often equipped with trivial controls. It is unlikely that repairing a Vitek blender will require in-depth knowledge of circuitry.

Let us add that reusable thermal fuses have been observed that, after tripping after a given period of time, restore the circuit. Others are designed for 100 cycles of operation. Decide for yourself whether the operating resource is sufficient relative to your own view of the device. Let's list what can break (power supply):

- filters;

- diode bridge;

- transformer;

- generator;

- key transistor;

- rectifier output diodes;

- varicaps;

- circuit breakers.

Repairing blenders yourself will require knowledge of basic electronics. Nothing complicated, based on requests in the comments, we will create a topic describing the topic of power supplies. Anyone who is in the know can repair a blender on their own without any problems.

Can a microwave be placed on a refrigerator?

Household appliances are created to make our lives more comfortable, easier and more enjoyable. Leading manufacturers are releasing many new models with improved characteristics. The stores have a huge selection, and customers are lured with discounts. I want everything at once. And therefore, in the kitchen in many families, more and more household appliances accumulate, often superfluous and completely unnecessary.

But there is technology that we can no longer do without in everyday life. The main one in the kitchen is the refrigerator, which has practically become a member of the family. Thanks to it, food remains fresh for a long time.

And you can heat them up in the microwave. Of course, a gas or electric stove is suitable for this, but a microwave is more convenient in this regard and, most importantly, much faster. These two household appliances complement each other.

But sometimes it happens that a tiny kitchen cannot accommodate all the equipment on its square meters, even such necessary and important ones.

Everything is clear with the refrigerator. He always is and will be. But with a microwave, which is usually purchased after the refrigerator, you may have problems finding a place in the kitchen. It’s good if we found a shelf in the kitchen unit or a separate stand. But the kitchen is already furnished and equipped with appliances. Therefore, there may not be a separate corner for such a necessary and not very large device. This situation leads to the fact that the microwave oven rests on top of the refrigerator, since there is no way to keep them side by side.

Device design

The most commonly used blender is a hand blender. If it is equipped with a rotating bowl, it turns into a stationary one and significantly increases its capabilities.

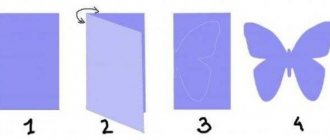

Before you begin repairing a blender, you must first become familiar with its design. The device includes:

- Sealed plastic housing.

- Electric motor with surge protector.

- Switch.

- Speed controller.

- Replaceable nozzles.

Depending on the type, the electrical circuit can be significantly expanded. Power is supplied from a household electrical outlet with an alternating voltage of 220 W or a built-in battery, charged via an adapter.

The principle of operation of the device is to transfer the rotational energy of an electric motor through an adapter directly to the nozzle. High speeds allow you to use the blender as a chopper or juicer. By adjusting the rotation speed, you can obtain the optimal consistency of the prepared mixture.

Nozzle does not rotate

The first thing to check is the container. Remember, there are warning marks on the bowl, above which you cannot place food. If this rule is neglected, the nozzle stops rotating. In order to bring the structure into working condition, you need to pull the contents out of the overfilled container and fill it in small portions.

If the attachment sticks, you should remove it, clean the knives, and then apply a safe food-grade mineral lubricant to the shaft.

If all operations to eliminate the problem have been completed, and the element does not rotate, it is worth checking the electric motor of the device. To do this, you need to take it to a service center.

Leakage in the bowl

Rarely, but sometimes the following picture is observed - the blender works normally, but puddles appear around. A similar malfunction usually occurs when the oil seal leaks. Repair consists of replacing it with a new one. However, before replacing, make sure there are no cracks in the bowl.

Never load the bowl completely. In this case, leakage from under the cover is inevitable.

Blender is quite simple. As you can see, it is enough to repair one unit, and the functionality of the device will be restored. Along with the benefits, doing repairs yourself is also fun.