Rust does not paint any surface... unless, of course, the owners of the house take a strange look at every flaw and notice something interesting and alluring in it. In order to clean traces of corrosion (and rust is precisely its result), it is worth using the VSN-1 rust neutralizer.

General information

There are many remedies that help cope with such consequences, but in our country the most famous are products under the names: VSN 1, astrochem and yaskhim. They are easy to find on sale in several popular volumes: 250 ml, 0.5 l and one liter.

The main advantages of the neutralizer

Considering the wide spectrum of action of this product, we can highlight the main advantages that make the rust neutralizer popular among buyers:

- Low price. This point is especially pleasant, because in our climatic conditions we have to resort to using this product quite often. You can buy a neutralizer at almost any hardware store.

- Safe composition. The product does not contain flammable or toxic substances.

- Economical. The product is quite easy to apply and requires minimal consumption.

- Efficiency. The neutralizer eliminates even old corrosion, thanks to its ability to penetrate deeply into the pores.

- Versatility. Can be used as a stand-alone coating and does not require any pre-treatment of the surface.

- Convenience. It dries almost instantly and at the same time significantly increases the service life of the treated products.

Application area

In construction, neutralizers are also widely used. Metal fences, poles, and hangars are at risk, but water pipes most often suffer from corrosion.

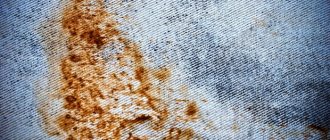

In everyday life, these products are used less often; rust mainly appears on garden tools and tools, but this can be avoided by following a number of simple rules.

Purpose and differences from converters

A neutralizer is sometimes confused with a rust converter, but these products differ not only in their purpose, but also in their composition.

The neutralizer is capable of stopping the processes started by corrosion and reduces the emerging rust to neutral elements; how it works can be described in three stages:

- The structure of the plaque becomes porous, which is what makes it easier to remove rust from surfaces

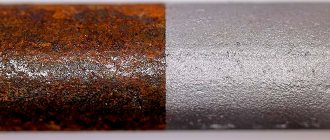

- The treated surface becomes even

- Rust breaks down into neutral components and completely dissolves

Safety of treated surfaces

We are talking about an aggressive product, which means it is worth mentioning precautions. Thus, one should not neglect the danger of car polish or bathtub enamel dissolving under the influence of “strong” acids in the solution. Simply put, we strongly advise you to carefully monitor how long the hero of our today’s article is in contact with the surface.

We hope that our material was useful for you, you learned something new and interesting for yourself and, perhaps, have already decided that on your next trip to the hardware store you will definitely buy a bottle of VSN-1 rust neutralizer so that it is always available hand. Let the metal surfaces in your home always sparkle and delight with their pristine beauty, and let rust bypass them seven ways: if anything happens, it will face certain death in the form of a neutralizer.

Top 5 proven products

On sale you can find formulations from different manufacturers and different release forms. However, there are neutralizers that are in high demand among consumers.

VSN-1

This is an inexpensive composition that is sold in plastic jars. It is liquid, so it is convenient to use for completely soaking products. It is based on orthophosphoric acid.

The product is suitable for cleaning different surfaces. When working with it, it is recommended to use not only gloves, but also a respirator. The average holding time of the composition on the metal is 30 minutes.

Pros of VSN-1: low price and high efficiency. Cons: does not protect against rust, but only removes it, since it consists exclusively of acid and water.

The average cost of 500 ml of solution is 40 rubles. Reviews can be found here.

Yashim

The neutralizer from Yashim is a product based on water, phosphoric acid and zinc salts. There is also a composition supplemented with hydrochloric acid. The product is suitable for working with any metal surfaces. It is produced in plastic bottles with a screw-on cap. The exposure time on metal is 30 minutes. Pros:

- affordable price;

- high efficiency;

- rust protection.

The main disadvantage is the inconvenience of application, since the lid is not equipped with a dispenser. This requires strict adherence to safety regulations.

Price – 35 rubles per 0.5 l. Reviews can be found here and here.

"Chemist"

Composition from a Russian manufacturer. Contains acids and zinc. After processing, it leaves a film on the metal surface that protects against damage. The product is produced in plastic bottles equipped with a dispenser.

Pros:

- does not require rinsing;

- economical consumption;

- Ease of use;

- high efficiency;

- corrosion protection;

- affordable price.

There were no downsides to the composition.

Price - 160 rubles per 1 liter. You will find reviews here and here.

Astrohim

The product is made on the basis of organic salts, contains a film former and tannin, as well as auxiliary components that improve the quality of cleaning. The liquid is poured into plastic bottles, with and without a dispenser.

Pros:

- ease of application;

- multi-component composition that effectively copes with rust and prevents its reappearance;

- the product can be used for prophylactic purposes.

The disadvantages of the composition include a pungent odor. Price – 200 rubles. Reviews can be found here and here.

AUTOPROFI

The product is available in the form of a spray. It is used to remove rust and prevent its reappearance. The composition forms a protective film on the surface, so it does not require rinsing.

Pros:

- high efficiency;

- ease of application;

- rust protection;

- no pungent odor.

There are no downsides to the product. The only drawback is the slightly overpriced cost compared to other formulations.

Price – 220 rubles. You will find reviews here.

What do consumers say?

But in theory, it is impossible to be convinced of the good (or, on the contrary, bad) properties of the VSN 1 composition, so many of us tend to look for real reviews on the Internet. In order to make the task easier for our readers, we ourselves have read many publications of ordinary people, and now we can say with confidence that the majority of users of the Russian-speaking segment of the World Wide Web praise the neutralizer for its effectiveness and profitability (as of the end of May 2016, a 0.5 liter bottle of the composition can be purchased for 40-60 rubles, which, of course, is very cheap - in Moscow, for example, even travel costs more). However, these same people argue that behind the effectiveness lies aggressiveness and unsafety: the neutralizer is fire hazardous, can damage the mucous membrane when inhaling vapors, and generally requires careful handling. True, the low price and efficiency still cover these disadvantages, which are invisible when handling the liquid properly.

We recommend: How to prepare antistatic agent for clothes at home?

What is a rust converter, what does it do and what is it for?

Rust converter is a water-based product used to combat rust. The converter contains two active ingredients: tannic acid and an organic polymer. The first ingredient reacts with iron oxide (rust) and chemically converts it into iron tannate, a stable, dark-colored material. Tannins are a group of water- and alcohol-soluble natural products extracted from fruits, trees and herbs. The second active ingredient, 2-butoxyethanol, is an organic polymer that provides a protective primer layer. The overall chemical reaction transforms the rust into a durable black protective polymer coating that serves as an excellent primer for oil-based and epoxy paints.

It is important to understand what exactly a rust converter is used for. In most cases, the converter is not intended for bare metal, although there are some brands on the market that have changed their formula so that they can be used as a primer

However, the rust converter still will not provide the same protection if used on bare metal. Instead, the rust converter should be used directly on the rust.

Instead of removing rust, the converter chemically mixes with the rust to create a black, inert substance that can be painted over, hiding the presence of rust and preventing further corrosion.

Application and principle of operation of the rust converter

When choosing a product, the degree of deformation of the metal by rust is very important. Regardless, the ideal level of rust for any converter is moderate to severe. Keep in mind that if your car is heavily rusted, you will still need to sand the metal smooth.

Types of rust neutralizer

Today on the market there are a large number of options for neutralizing rusty deposits on the surface of metal products. Depending on the composition, neutralizers are divided into the following types:

These solutions are used as a primer. They transform rusty deposits into a homogeneous substance that covers the metal with a thin film and makes its surface ideal for applying paint and varnish products.

Stabilizers modify the structure of the corrosion product. They make it more uniform and stable for easy application of varnish or paint. In this case, the metal oxidation process stops.

They make weak rust substances from active substances that are easily removed from the surface.

Table 1. Value of coefficient α for some metals (coefficient (Pilling-Badwords factor)).

Metals for which α

Articles on the topic

Phosphating

Today, a large number of methods are used to protect metal products from the formation of corrosive plaque. All of them are aimed at creating a thin protective layer on the surface that will protect against the process of metal oxidation for a long time.

Rust removal

Today, many people are faced with the formation of rust on metal surfaces. It is formed under the influence of the environment. The process of formation of rusty plaque can have different durations.

Rust converter - which one is better?

Today, a large number of mixtures are produced for treating metal surfaces. There are special compounds that help fight the formation of corrosion plaque. They are called rust converters.

Release form and functional principle

The risk of corrosion is neutralized in liquid form, poured into containers of different sizes, most often 0.5 and 1 liter, but there are also embodiments in which the customer BCH 1 customer in a 5 liter container serves, but rarely

Before we talk about the influence of the substance itself, we will digress a little and remember the school history of inorganic chemistry. Rust in everyday use is generally a contact product between iron and oxygen in the presence of water or air. In other words, rust is mostly iron oxide. We also note that this is just a general term and therefore not every iron oxide is a rust, the word means the result of corrosion.

Iron oxide is amphoteric, that is, one that can have the properties of acids and bases. This is why the BCH 1 composition is included in the neutralization of chemicals in reaction with rust contrasts, so the neutralized acid base, i.e. alkali

Manufacturers do not provide a detailed list of substances used in the production of the catalyst, but the curious have done analysis and found that, most likely, a convoy of sulfuric or hydrochloric acid (in other words, a “strong”, aggressive acid) dissolves the rust and makes it vulnerable to removal . In addition, sometimes manufacturers use orthophosphoric acid together with one of these acids

However, you should use the neutralizer with caution, do not inhale the fumes when working to cover exposed skin

Is it possible to make a rust modifier yourself?

If it is impossible to purchase a modifier, you can make it yourself. The simplest way is to mix phosphoric acid with water in a ratio of 6:4. However, finding acid is sometimes quite difficult.

In this case, you can use the following recipe:

- 1.5-2 liters of boiled water;

- 1.5-2 l of citric or oxalic acid;

- 15 g baking soda.

First you need to mix the first two ingredients. After this you should add soda. The reaction lasts about 35 minutes. The converter is ready for use.

It is recommended to apply the resulting solution to the damaged area with a cloth made from natural materials. During the process, it is necessary to ensure that the surface remains wet for at least 15-20 minutes.

You can find out how to make a rust converter yourself here.

How to make a converter with your own hands

Before resorting to a certain mixture, check the quality of the paintwork on your car. Quite often it happens that it will be difficult to paint the surface after the rust has been converted.

In addition, it is important to think about personal protective equipment - contact of substances of this type with the eyes and respiratory tract of a person is especially dangerous.

If you don’t know how to choose a suitable converter in the store, we have prepared step-by-step instructions that will help you make the composition yourself:

- prepare a 12-30 V battery, soldering acid, a piece of zinc, a clean rag and a long wire;

- wrap the zinc in cotton wool and then in a rag to make a tampon;

- We attach a self-tapping screw to the zinc, and to that a wire that will connect the tampon to the battery terminal (plus);

- treat the rag with soldering acid, do not forget about gloves;

- apply our swab to the corrosion site, wait for 10 minutes;

- wash off the remaining acid.

How to use VSN 1 correctly?

The method of using rust neutralizer VSN 1 is indicated on the product label. It is important to strictly follow the instructions to get the maximum effect from the procedure.

Before treating the product with the solution, it is recommended to remove dirt from its surface and clean off formation rust. The neutralizer can be applied to a damp surface.

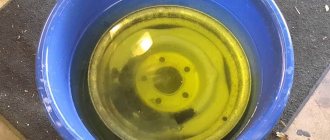

The instructions indicate that it is better to apply the gel product with a brush or a swab soaked in the product. However, in practice it turns out that this is not convenient. If the area to be treated is large, it is better to soak a rag or piece of rags in the neutralizer and apply it to the rusted surface. It is better to treat small-sized objects by immersing them in a plastic container filled with a neutralizer solution.

The cleaning procedure should be carried out at a temperature in the range of 10-30 degrees. The exposure time of the product in the solution is 30 minutes. After this time, a whitish coating should appear on the treated surface. After this, the workpiece or surface is washed with clean water and dried or allowed to dry naturally.

Note: the solution can be frozen. After defrosting, its properties are retained.

The cleansing procedure should be carried out in a well-ventilated area or outdoors. It is imperative to use personal protective equipment - a respirator or gauze bandage, gloves, goggles. If the liquid gets on exposed areas of the body, the skin should be washed with water. The composition is flammable and must be stored away from sources of fire and away from children.

Rusty plaque removers have found wide application in everyday life. These liquids are available and easy to use. With their help, you can restore rusted metal products to their original appearance and continue to use them for many years to come.

The second difference is the composition

So, we found out that a neutralizer is a subtype of a converter. We will not use this term further to avoid widespread confusion among builders. Let's see how rust converters differ in composition.

The converter converts oxides of iron and other metals from rust into a protective chemical barrier. First of all, ferric oxide (Fe2O3) enters into a chemical reaction.

According to their structure, rust converters are of 3 types:

- Aerosol.

- Liquid.

- Gel.

There are 2 types of converters based on their effect:

- Primer (or coloring).

- Rust removers (the same neutralizers).

Ground (painting) converters

Ground converters, which in everyday life are usually called simply converters, consist of 2 main components:

- Tannic acid.

- Organic polymer: ethylene glycol monobutyl ether or butoxyethanol.

Some converters also add organic or inorganic acids to lower the pH of the environment:

- Tamak.

- Ferum-3.

- Runway.

- LOCTITE 7505.

When applying soil converters, the rust darkens and turns black. Ferric oxide (Fe2O3) turns into a sticky neutral layer that will last 1 to 3 years (depending on thickness, composition and operating conditions). After this period, it is advisable to reapply the converter.

Please note that the soil converter is best used on carbon or low alloy steel. The thickness of the corrosion layer should not exceed 100 microns

Converters that remove rust (neutralizers)

This substance doesn’t just break down rust. It also reacts chemically with substances from the rust, resulting in the formation of other chemical compounds. The same transformation process occurs. The resulting compounds are split off from the metal without affecting it. The rust can then be removed, thus clearing the metal of its oxides (corrosion layer).

The main component of neutralizers is acids:

- Sulfuric.

- Solyanaya.

- Nitrogen.

- Phosphorus (most common).

- Vinegar.

- Lemon.

This type of converter can damage metal that is not affected by corrosion. To prevent this from happening, corrosion inhibitors and metal passivators are added to the composition:

- Zinc oxide.

- Manganese oxide.

- Organic-based corrosion inhibitors.

Acids do not react with pure metal (not affected by corrosion) due to 2 mechanisms:

- Formation of phosphate layers with manganese and zinc.

- Acceptor electron effect of organic corrosion inhibitors.

How to work with such a converter:

- Apply the mixture to the rust (in some cases the mixture is applied with a brush, in others with a spray can).

- Wait 10-20 minutes (depending on the temperature; the higher it is, the less time you have to wait). Heavy-duty rust converters, such as Poliform, need to be washed off before they begin to thicken. Otherwise, you will have to apply a converter to liquefy the reaction products.

- Now remove the chemical reaction products between the converter and the rust. If there is still rust on the metal surface, repeat step 1. When using reinforced converters, the metal surface can be additionally passivated - heated to 60 degrees. A regular hairdryer will do for this. The second option is to dry the metal surface in a dry room for 24-48 hours (if the product can be removed and moved).

- Finally, you can apply the paint.

Advantages of a rust removing converter (neutralizer):

- You visually control the removal of rust.

- The chemical reaction occurs very quickly.

- Complete rust removal.

- The cleaned metal surface has increased adhesion to the base and is easier to paint or treat with various compounds.

- Possibility of using paint corrosion inhibitors that work on pure metal.

Neutralizers also have disadvantages:

- Acids are dangerous to health, so you need to work in gloves, glasses, aprons, and when spraying, in respirators.

- Complicated operating instructions.

- If moisture gets on the rust, efflorescence will form during a chemical reaction, which will also have to be vigorously wiped off. So you need to apply the neutralizer only to a completely dry surface.

- If there is a thick layer of corrosion, you will have to remove the rust for a long time. Repeat the procedure 4-5 or more times until the rust is completely removed.

Buy with this product

Price for: pcs Article: not specified Availability: Severo-Yeniseiskaya, 40 (Krasnoyarsk) Koroleva, 1G (Krasnoyarsk) Maerchaka, 102 (Krasnoyarsk)

Delivery throughout Russia and the CIS

Before ordering measured goods (meters, kilograms, etc.), consult our specialists. Distribution of measured goods is possible with an error of 2-3 cm and/or 3-5 g. Before paying for the goods, wait for the operator to call; balances may vary. Also check out the list of goods prohibited for shipment

- Comments

Delivery in Krasnoyarsk and Russia

Delivery in Krasnoyarsk:

— When ordering from 5,000 rub. delivery is free on weekdays from 10 to 18 (except for large/heavy orders) for individuals; — For orders less than 5,000 rub. delivery is paid separately, 200-700 rubles. depending on the area of the city; — Delivery is carried out within 2 working days from the moment the order is confirmed.

Delivery across Russia:

- Post office;

— EMS and other express delivery companies; - transport companies; — delivery is carried out only from KrasnoYarsk (delivery is not carried out from KrasnoDar, it is only possible to purchase goods in the store itself). If iron and its alloys are stored improperly, for example, in conditions of high humidity, they can become rusty. Everyone has seen the reddish-red rough coating on the surface of the metal. The rusting process starts when there is moisture in the surrounding atmosphere. If a drop of water falls on the iron surface, its color will change after a while. First, the drop will become cloudy, and later a brown spot will appear in its place - the iron has corroded. When rust forms, the rust neutralizer VSN 1 can return an iron product to its previous appearance. Read the article about what this product is and how to use it.

The best rust converter for cars

The most common cause of car body corrosion is electrochemical attack, which occurs as a result of the action of vapors from an electrolytic solution on metal body parts that have minimal protection. The situation is aggravated by road reagents traditionally used in winter.

DOCKER NITTRONN

Neutral rust converter Nitron based on tannins, corrosion inhibitors (retarders) and functional additives. Plant tannins (hydroxycarboxylic acids) convert iron oxide into tannate complexes, which firmly bind rust particles at the molecular level to each other and to a clean layer of metal. In addition, tannin has inhibitory properties. Due to the high concentration of additives, the solution penetrates deeply.

DOCKER NITTRONN

Apply in two layers. Since the neutralizer is tannin, there is no need to rinse after processing, which is good news. But it is necessary to paint immediately after drying. For example, the most problematic area - the connection between the exhaust system flange and the muffler flange - is best painted, for example, with heat-resistant paint or varnish.

Pros:

- quality;

- low price;

- Effect.

Minuses:

the smell is too strong.

Runway Rust Converter

Rapidly transforms rust into a durable protective structure. The effect has a double effect - it inactivates the formation of corrosion, forms a passivating protective coating that does not allow air and moisture to pass through.

Runway Rust Converter

The consistency is similar to PVA glue, does not spread, and covers well. It copes only with relatively new lesions; it is powerless against “old” rust, even if several layers are applied. It is not recommended to use it as a preventive measure, only after identifying problem areas.

Pros:

- dense protective layer;

- good covering ability.

Minuses:

- only works with “new” rust.”

- price.

Permatex

It is a white rubber-latex coating that dries quickly and is converted by metal oxides into a black, strong polymer film. Available in the form of a gel, after drying it forms a reliable protective layer on the surface being treated.

Permatex

Permatex is used to stop and eliminate corrosion, prepare metal surfaces for painting and protect them. Apply a thin layer to the previously cleaned area and leave for 30 minutes. and then a second layer is applied. After complete drying, you can begin painting.

Pros:

- release form - does not spread and completely covers damaged areas;

- after drying, the layer is very dense; according to reviews, corrosion does not form in these places for 2-3 years.

Minuses:

price

Tsinkar

A good converter, high quality, the corroding effect is immediately visible. In addition to orthophosphoric acid, the composition includes zinc ions in high concentrations, which eat into the metal on a molecular basis, after which they prevent moisture and oxygen from oxidizing the metal.

Tsinkar

Pros:

- price;

- efficiency;

- Corrosion begins immediately after application.

Types of tools and features of their work

How to choose the most effective rust converter? Pay attention to the composition of the product, its degree of viscosity, application method and additional functions - hydrophobicity, pigmentation, special protective equipment. The first composition creates a special protective layer, while the second is necessary to destroy oxidation products and prevent further destruction of the metal

The first composition creates a special protective layer, while the second is necessary to destroy oxidation products and prevent further destruction of the metal.

The following types of compounds are sold:

Phosphating rust converters

This type of composition is aimed at working with aluminum and ferrous metals. They got their name due to the main active component - here its role is played by orthophosphoric acid.

The product performs especially well when using metal in environments with a high level of acidity.

Among specific formulations, we recommend “Phosphomet”. This is an aqueous solution that contains not only the active substance, but also the inhibitor. Shows itself with galvanized products, cast iron, aluminum.

It is also worth paying attention to Phosphomet-Zima. The composition was created specifically for outdoor use in the Russian climate. The operating principle itself is relatively simple

Phosphoric acid activates film creation. The layer will be chemically inert

The principle of operation itself is relatively simple. Phosphoric acid activates film creation. The layer will be chemically inert.

Research shows that the composition of such a film is dominated by iron, zinc and manganese salts. An excellent level of adhesion is ensured, the film will be very difficult to damage.

This type of product is applied using any method convenient for you. The manufacturer indicates that only those places on the material that have actually been affected by corrosion can be treated using these methods.

Acid negatively affects zinc - galvanized areas can be damaged due to accidental contact with the surface.

A paint coating can be applied to the top of the composition only after the surface has been dried. On average, this does not take up to two days.

The choice of this category of compositions is supported by its versatility. The product can be used both in summer and winter. The requirements for surface treatment are minimal - you can do without washing it.

When using the composition, it is worth remembering that it contains acid. Therefore, we must not forget about the use of special personal protective equipment. Avoid contact with eyes and skin.

If this does happen, the affected area will need to be rinsed with running water as soon as possible. If it gets into your eyes, you should immediately consult a doctor to prevent a chemical burn.

Neutral rust converters

The main advantage of the neutral composition is that it does not contain acids.

This makes the solution much less dangerous to humans and prevents damage to the material during use.

Most types of neutral corrosion modifiers are tannin based. This is a natural component.

Among specific examples of these types of neutralizers, it is worth paying attention to “Armasil”. The composition is designed specifically for application to rolled metal, fittings and other types of ferrous metals

The composition is designed specifically for application to rolled metal, fittings and other types of ferrous metal.

A durable film up to 150 microns thick will be created on the surface.

The principle of operation of this type of product is quite simple.

Metal oxides begin to be converted into corrosive inactive compounds.

In this case, the coating itself will be as durable as possible.

The rust itself can change color and turn black.

The application process is simplified as much as possible - you can spray the composition onto the metal or coat it with a brush or roller.

Treatment by dipping into a bath of solution is also possible. Drying takes no more than three hours.

The possibility of coloring the metal speaks in favor of choosing this type of composition. This will help you understand which areas of the metal have been treated and which need additional impregnation.

You can use tannin-based compounds outdoors.

The composition is safe for health because it does not contain acids or other aggressive substances that can cause real harm to the body.

Despite this, you will need to use personal protective equipment during processing, and if the composition gets into your eyes, you should consult a doctor.

Effect of rust neutralizer

A rust neutralizer is a substance designed to act on an existing coating of one of the corrosion products. The principle of its operation is that when the active substances of the solution and corrosion products interact, they turn into neutral elements that can be easily removed from the metal surface.

Nowadays, the use of anti-rust and anti-corrosion products is a necessity. Thanks to this, you can extend the life of any metal product. Today, very often rust converters or neutralizers are used for cars. To carry out paint and varnish work, it is necessary to carefully prepare the surface. It is not uncommon for the surfaces of an old car to already have a dark brown coating. It is quite difficult to remove it using all the usual methods. In such a situation, a rust neutralizer will cope.

After using neutralizers, a thin protective film is formed on the surface of the metal product. It is resistant to temperature changes and aggressive environmental conditions. It is thanks to it that the metal acquires an even structure and additional strength and protection. As a result, all oxidative processes completely stop.

Thanks to such solutions, the strength of the metal is preserved due to the fact that the source of rusty deposits is completely eliminated.

Today there are a large number of neutralizers or converters of rusty deposits on the market. They are made on the basis of different components and act on rust as follows:

- make the structure of rusty plaque more porous for easy removal from the surface.

- make the surface smoother by binding rust elements. Its structure becomes more homogeneous. It turns into a thin film covering the metal.

- The rust is completely dissolved, which makes it much easier to remove.

What is it, what is it for, how does it work?

A rust converter is a chemical compound.

How does it work? After application to the damaged area, orthophosphoric acid, which is part of most modifiers, acts on iron oxides, especially iron (III) oxide.

As a result of the chemical reaction, a protective barrier is created by converting corrosion products.

If the converter contains zinc compounds, then the principle of operation looks different. Zinc atoms combine with oxygen, thereby forming a film. It provides protection and prevents the formation of rust in the future.

Additional components also take part in the chemical reaction, responsible for ensuring the inactive state of the protective layer formed on the surface.

You can find out what a zinc rust converter is and how it works here.

Instructions for use

We decided that it would not be amiss to also post instructions on how to use the rust neutralizer, since, unfortunately, there are no practical tips on the bottles.

- The first step is to determine how bad everything is: the area of the affected surface, the height of the rust, check whether it is peeling off.

- Then, if the rust does flake off, try to remove it with a wire brush or sponge, if you have something like that.

- After this, you can try applying a neutralizer.

Advice

The best thing to do is pour the liquid onto a scrap rag and place it on the rust. Before doing this, of course, it is important not to forget to put on gloves.

- After some time, you can check the result. If the reaction proceeds as required, all rust will be washed off from the affected surface. If not, it’s worth trying again, especially if the poured composition simply wasn’t enough.