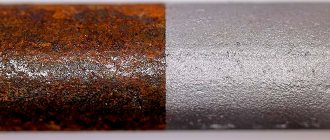

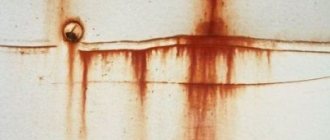

The appearance of rust on metal products is so common that this red-brown coating is already taken almost for granted. Over time, under the influence of moisture and air, various surfaces, workpieces, tools and parts lose their appearance. If no steps are taken, the metal will quickly begin to deteriorate, so traces of corrosion must be eliminated immediately. However, first you need to find out how and with what you can remove rust from metal at home. There are quite a lot of life-saving remedies to get rid of dangerous plaque. In this case, they use products that are familiar to everyone, but in an unusual role for them, as well as special anti-rust preparations. But the effectiveness of both depends largely on the degree of damage to parts, pipes, tools and other metal objects.

Nitric acid

A weakly concentrated 58% solution can be purchased without any permitting documents in departments selling chemicals.

You can remove rust with nitric acid in a matter of minutes. For metal processing it is diluted to 10%. But acid can also poison the metal itself. Therefore, carrying out such experiments requires some experience.

The concentration of the solution intended to remove rust will need to be accurately calculated depending on the amount of metal. You will also need to monitor the process: as soon as the acid reacts with the oxide, the process of metal decomposition may begin. Plus, when working with such solutions, you need a high-quality exhaust hood and strict adherence to safety precautions.

Since acid can corrode not only rust, but also metal, this method is not suitable for processing metal-cutting tools (for example, dies, taps). The thread diameter can change significantly. Acids are especially dangerous for carbon steels. The more carbon they contain, the more damaged the metal will be.

Some unusual means and methods to remove rust from metal

The list of working anti-corrosion compounds is not complete. There is also Coca-Cola, beloved by many, tomatoes and the electrolysis process.

Coca Cola

Glory to the meticulous American housewives who were the first to notice how a tasty drink can corrode iron oxide. And not only the rust is eaten by the cola, but also the nail itself. There is nothing surprising in this; grapefruit acts in much the same way: both Coca-Cola and the fruit contain phosphoric acid.

How to remove rust from a bicycle? Or how to clean a rusty hammer? Buy a cola and give the item a good bath in it!

It is important not to miss the moment when the object has been cleaned and the drink has not begun to corrode the metal itself.

Salvaging metal from the garden or kitchen: tomato paste or ketchup

The chemical composition of tomato allows it to be used not only for food.

Homemade or store-bought tomato paste will do the job; it’s an excellent tool at hand.

Ketchup or paste is dripped onto the rusty metal, but not washed off immediately: let the substances interact. After 10-15 minutes, the dirt is removed mechanically, and the surface is wiped with a dry cloth.

Hydrochloric acid

It acts as quickly as nitrogen. The metal begins to turn white literally before our eyes. Since the reaction process produces hazardous gases, you should not get too close to the container in which the treatment is being carried out.

A slower, but also safest method of cleaning is to mix the acid with flour. Its addition will significantly reduce the rate of metal etching. However, it will take more time to remove the rust. You can also try adding methenamine, which is a corrosion inhibitor (suppressant), to the hodgepodge.

When processing any of the acids to neutralize its residues, the product must be washed in ammonia or a weak alkaline solution of soda or soap. Please note that after removing the oily film, the metal product can literally turn red again within half an hour. Therefore, after cleaning with an anti-rust agent, it must be immediately wiped dry or thoroughly calcined so that the water completely evaporates.

The part is then lubricated, coated with a layer of zinc or painted. If it is not possible to treat the metal with an anti-corrosion compound in the near future, it is coated with a spray bottle with a mixture of lithol (solidol) and gasoline.

Specialized drugs

If folk life hacks don’t help or the rust gets too deep, use a special anti-corrosion substance. You can purchase the product at any hardware store. During handling, be sure to wear protective gloves and a mask. Strictly follow the manufacturer's instructions so that you do not damage the metal while removing rust.

1. Neutralizers and converters

Chemicals should be used in complex and advanced cases

Chemicals that prevent the spread of corrosion. After applying the product to metal, the substance reacts with iron and forms a protective layer on the surface of the material. The film will remain on the product for a certain period of time, and then the procedure will have to be repeated. The products protect the material from the negative effects of oxygen and moisture.

2. Paint

Paint will prevent rust from spreading

You can use oil paint or a special rust stain. Regular paint should be applied to a surface that has been previously cleaned of corrosion. However, the disadvantage of this method is the possibility of rust progression under the painted layer. It is better to use special paints that can be applied directly to areas with corrosion. The product prevents the spread of rust by stopping the oxidation of the metal.

3. Primer

Primer enamel converts rust into a protective layer

In addition to regular primers, there are also varieties for working with rust. The operating principle of the product is to convert corrosion into a protective film. Prime the surface to level it, and treat it with special paint on top.

Phosphoric acid

This method is perhaps the most common and safest. After all, phosphoric acid does not remove the oxide layer, but turns it into a film that can serve as an anti-corrosion coating. However, this method is only suitable for metal products that are only slightly affected by rust.

There is a special product on sale called “Anti-rust”. It is made precisely on the basis of orthophosphoric acid. True, such a solution acts a little slower.

If the plaque is large enough, it is better to use a combination of the first and second methods. First, treat the part with hydrochloric acid, and use phosphoric acid to only record the result.

Rye solvents

All of the products listed below are in great demand (everything is simple and affordable) and effective. Each of the compositions necessarily contains a certain type of acid that effectively copes with and prevents corrosion.

What should those who purchase solvents remember? They are produced for outdoor use and hidden surfaces. The difference is in the method of use, the indicator of aggressiveness towards various products - paintwork, rubber, plastic. We recommend that you read the review: how to remove glue from a sticker from plastic.

Specialized solvents have excellent deep penetrating ability (even for microcracks), an increased degree of adhesion to the base, and do not harm paints and varnishes. We recommend a review: can varnish be applied to nail polish? Rye destroyers are produced in the form of: sprays, aerosols, liquids, gels.

Let's look at the most popular ones:

- "LOCTITE 8019 400 ML" - spray. The best option when you need to disconnect rusted fasteners. It has a convenient elongated spout for application in hard-to-reach places.

- "Neomid 570" - liquid, concentrate. Designed for external and internal processes on concrete, ceramics, stone, metal, paint and enamel.

Vinegar or lemon

You can even remove rust from metal using these acids. The cleaning method is simple and safe. The metal product is placed in a solution of citric acid (a couple of 20-gram bags will be enough for 2.5 liters of water). Large surfaces are sprayed with a spray bottle.

The exposure time depends on the degree of damage to the metal. As a rule, it is no more than a day. You can do it differently. Soak the part in the solution for a couple of hours, and then rub the softened layer with a metal brush or foil. It will come off easily. To speed up the process, the citric acid solution can be pre-boiled.

Another advantage of citric acid treatment is the possibility of further galvanizing without pre-cleaning. Zinc will not adhere to the phosphate film formed as a result of the interaction of “rye” with orthophosphate acid. Another advantage is that lemongrass does not affect varnished or painted surfaces.

Processing with vinegar is carried out in the same way. The greater its concentration, the better. You can even use a 70% solution. When you add regular salt to the vinegar (pour enough of it until it stops dissolving), the effect will increase. If the layer of plaque is large, before cleaning the rust with acid, the surface can be treated with an iron brush or sandpaper.

Rust converters

The modern market offers a wide range of converters to eliminate this particular problem. By coming into chemical contact with the oxide, the product effectively neutralizes it and forms a protective, stable layer. The reagent reacts quite quickly after about 15 minutes, and this is one of the irrefutable advantages of the substance.

There are 3 main types:

- Acid-free. The active ingredient is vegetable tannin. Advantages: they are not afraid of water and are used to protect metal structures.

- Neutral. The active substance is based on zinc.

- Acidic. The active substance is orthophosphoric acid. The disadvantage is that only dry surfaces are treated with liquids.

Our most popular ones are:

- “Loctite 7505 (Super Growth Killer)” is a substance based on synthetic latex. After 1.5-2 hours, the product applied in two layers transforms the plaque into a dark, strong base, ready for further coating.

- “Docker Ifkhan-58PR” is a mixture, absolutely harmless, often used in everyday life, the active component is organic tannin.

- “Zinkar” is a liquid, the active substance is orthophosphoric acid in the composition with zinc, forms a strong complex-element resistant film.

- “Fenom” is a solution based on orthophosphoric acid, withstands various welding processes, the hard layer makes the adhesion of the metal to paintwork materials or bitumen coating more than three times.

- “Permatex” is a liquid gel, should not be washed off, used before painting automobile bodies, acting as a primer.

- "Kudo KU-70005" is a substance, an effective product for chips and scratches due to its high-quality penetrating ability.

- “Autoprofi”, “Rust Remover”, “Eltrans”, “Kolchuga” are popular aerosols and sprays, the effectiveness of which is deservedly appreciated by the majority of consumers.

ADVICE! Before choosing and purchasing a converter, it is first recommended to consult a specialist. Clearly assess the specific problem and determine its size, think about what end result you want to see, and start making a choice.

Using electrolysis in soda ash

This treatment allows you to keep even chrome surfaces intact. Using soda ash we will obtain carbonic acid, which will clean the metal.

We'll tell you how to clean rust from metal in a similar way:

- When making a small amount of solution, even an old phone charger can serve as a power supply. To process a significant volume of parts, you can take, for example, an old computer power supply.

- It is necessary to connect a minus to the workpiece, and a plus to the electrode.

- For better conductivity, the area to which the wire will be connected must be cleaned with sandpaper.

- A suitable sized piece of tin is used as a positive electrode.

- In 3-4 hours of such treatment, even significant layers of iron oxide can be removed. If necessary, electrolysis is repeated.

- Remaining rust can be etched in a vinegar solution.

You can get rid of rust at home using any of the methods described above. For processing large parts, the use of acids is acceptable. Cleaning metal-cutting tools and machine parts in this way to avoid etching of the metal is unacceptable. It is better to subject them to electrolysis or place them in a solution with kerosene or diesel fuel.

Protecting metal from corrosion

In order to provide reliable protection to the metal from the formation of corrosive processes, various techniques are used. Each of them is unique and has certain characteristics.

Methods of protection against corrosion:

- Chemical coating. In most cases, these are thin oxide films that form on the surface of the structure under the influence of steam and air. One of the common methods of oxidation is the treatment of products in a solution of nitric acid heated to a temperature of 140 °C.

- Paint layer. The main disadvantage of coatings is their low resistance to sudden changes in temperature and mechanical damage.

Chemicals

You can remove the unattractive red coating from the surface with a wire brush or sandpaper. Sandblasting can also come to the rescue, but not every home has it. Small parts are difficult to process mechanically, and it is difficult to wipe off old marks with sandpaper, so it is worth choosing a simpler and more effective method to solve the problem.