How to disassemble a Samsung machine yourself?

Instructions for disassembling a Samsung washing machine:

Remove the cover.- Remove and distribute for detergents.

- Remove the control module.

- Remove the service panel.

- Remove counterweights.

- Dismantle the heating element.

- Remove the belt.

- Detach the center and rear panels.

- Remove the tank with the drum, disconnecting it from the springs.

- Remove the bottom cover and unscrew the motor with counterweight.

The wires must be disconnected carefully, being careful not to damage them. It is better to record the entire disassembly process on camera so as not to get confused during subsequent installation. Detailed instructions for disassembly are here.

Breakdowns

An automatic washing machine from any manufacturer can fail, and Samsung is no exception. There are certain parts that, for a number of reasons, break over time. Here are typical ones:

- heat electric heater;

- drain pump;

- engine;

- control module;

- hatch handle;

- drive belt;

- water fill valve;

- bearings;

- shock absorbers;

- UBL.

Pressostat

Note that the pressure switch is a reliable part and rarely fails. All of the listed components break down only after a certain wear and tear, usually after 10 years of operation. Or in case of violation of the use of the machine.

This is not to say that this SMA has weak points. Except for the electrical wiring. The length of the wires is precisely calculated, and they are laid without reserve. Everything is tied into bundles very tightly. Sometimes this causes the wire to break at a bend. Therefore, in the event of a malfunction, we call all the loops.

When does the drain hose need to be replaced?

Replacing the drain hose is required in three cases:

- the hose is too short, connection difficulties arise;

- there is mechanical damage on the hose;

- the hose is so clogged with debris and scale that the blockage cannot be removed.

If the blockage is minor, you can get by by cleaning the hose. Read about replacing the drain hose here.

Pump

The drain pump must be in use for 8 years or more. Constant blockages lead to malfunction. They occur in the following elements:

- drain hose;

- pipe branch;

- pump.

The pump itself and the filter must be periodically washed and foreign objects removed. To carry out this procedure, open the small hatch on the lower right and unscrew the lid. There is a filter under the cover. We take it out and rinse with running water. We look inside and make sure that nothing is wound around the impellers. Otherwise we delete it.

Snail with drain pump

Important! There is always a small amount of water in the pump, so apply a cloth before cleaning!

With a clogged pipe or drain hose, everything becomes more complicated. To eliminate it, dismantling is necessary. There are two options:

- remove the front panel;

- turn the car on its side.

Both cases have their pros and cons.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! If you turn it over, be sure to cover the electric motor with plastic wrap!

What to choose: fix it yourself or call a repairman to your home?

If a breakdown occurs, the owner of a Samsung washing machine is faced with the question of whether to repair it himself or call a technician. To make the right decision, you need to carefully analyze the situation.

If the device is under warranty

If the device is under warranty, you should not attempt to repair it yourself . There is also no need to pay for the services of private masters.

Damage that occurs through no fault of the buyer is subject to warranty service. It is free, at the expense of the manufacturer.

If the device breaks down due to external factors, for example, it was dropped or connected incorrectly, you will have to pay for repairs yourself.

Repair it yourself

You can handle minor breakdowns on your own, for example:

- Replacing the pressure switch.

- Clearing the blockage.

- Rebooting the machine due to a controller malfunction.

- Replacing a pump, door hinge or hatch, etc.

If you have experience and capabilities, you can try to carry out more complex repair work, including:

- replacing the heating element,

- hatch cuffs,

- motor,

- shock absorbers.

The cost of repairs on your own is affected only by the price of the part and amounts to 2-3 thousand rubles.

If during the repair process you realize that something is not going according to plan, it is better to call a specialist.

At the service center

to entrust your washing machine to professionals in the following cases:

- controller is faulty;

- bearing replacement is necessary;

- dismantling of the tank or cross is required;

- The tank support broke.

Repairs that require complete disassembly of the washing machine are complex and time-consuming. Only experienced craftsmen can cope with it. If you try to intervene on your own, you can completely damage the washing machine.

The cost of repair by specialists will be from 2 to 7 thousand rubles for each breakdown, depending on the cause.

You will find all the most important and useful information about Samsung washing machines in this section of the site.

heating element

Hard water causes the heater to break down, resulting in scale formation. On the heating element, due to constant heating, it turns into stone and damages the surface. Note that in regions where there is soft water, for example, in St. Petersburg and the surrounding area, heaters practically do not fail. Moscow has hard water, and such damage is a pressing issue.

Removing the heating element

In order to extend the service life, use anti-scale products: Calgon, professional converters, or folk ones in the form of citric acid.

The malfunction manifests itself in two ways:

- The heating element burns out;

- leakage occurs on the housing.

In both cases, diagnosis is carried out with a multimeter. In order to gain access to the contacts, you must remove the front panel. See the disassembly sequence here. Unhook the wires. We put the tester to check the resistance.

First, we examine the contacts that receive voltage. If there is infinity between them, then replacement is necessary. Then we set the maximum limit.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! Reliable results can be obtained if the multimeter measures up to 40 MΩ.

We look at the resistance between ground and each contact. If the value is different from zero, then the heater must be replaced. Operation with current leakage will lead to incorrect operation and damage to the control module.

Repairing damage to a Samsung machine

We present to you a diagram of the device, which will come in handy for repairs. The technical content of machines of different brands is approximately the same. If you have already had to deal with replacing spare parts for a washing machine, then it will be easier for you to cope with the next repair.

List of components of the washing container: 1 – heating element (heating element); 2 – front part of the tank; 3 – front brackets, 5 pieces in total; 4 – heating element bracket; 5 – heating element spacers, 2 pcs.; 6 – screws, 3 pcs.; 7 – overlay; 8 – washer; 9 – screw; 10 – drum; 11 – sealing collar; 12 – rear part of the tank; 13, 14 – tank clamps, 9 pieces in total

Now you can start talking about certain types of breakdowns and how to repair them.

No. 1: unexpected stop during washing

The most common reason is insufficient water pressure. Then the machine stops, and to start it again, you need to turn it off and then turn it on again. If you have a lot of laundry loaded, in order for the machine to work, you just need to turn it off and remove the excess.

All problems with the washing machine stopping during operation can be dealt with quickly enough if you correctly determine the cause, which is not related to the failure of parts of the equipment

If there is a break in the power cord or an initially poor contact in the power button, then the device periodically turns itself off. The machine may also stop if it is not level and there is some misalignment.

No. 2: difficulty getting water

To fix this problem, you should first check the water pressure in the plumbing system and also make sure that the valve supplying water to the machine is well open.

If everything is in order, then you should check the filling valve, hose, and cleaning filter located at the inlet for debris and foreign objects.

You should know that the free end of the drain hose connected from below must be located at a height of more than 2/3 of the height of the device, otherwise water will immediately pour out of the machine.

No. 3: leakage from the unit

There are many reasons to explain this problem. Sometimes it is enough just to clean the powder container well - if it is clogged, water may simply leak out of it.

The most common cause of flooding caused by a washing machine is a damaged or disconnected drain or fill hose. Leaks can also occur when connections become depressurized.

If, after checking these hoses, you are convinced that everything is in order with them, then the reason lies in the o-ring.

It is necessary to check the tightness of the seals, both in the door and in the connection of the filling hose. If they are worn out, they should be replaced. Then you need to check the drain pump and hose for any foreign objects stuck in them.

No. 4: breakdowns and wear of the heating element

Therefore, the washing water does not heat up. This happens due to the failure of the heating element, but do not rush to change it - this may also be damage to the electrical wiring.

Therefore, you should carefully check the entire electrical circuit, as well as the contacts of the heating element itself, using a multimeter. If the tester shows the presence of voltage in the entire circuit, this means that the heating element will still have to be replaced.

In order to remove the heater, you need to disconnect all the wires and sensors, and then unscrew the nut securing it, then remove the heating element

The place where the heater is installed should be thoroughly cleaned, only after that it will be possible to install a new heating element.

No. 5: noise and vibration during operation

The most common cause of noise is improper installation of the machine. Because of this, the unit produces a strong hum during the spin cycle. To do this, the position of the machine must be leveled using a level.

But sometimes excessive noise can occur due to severe wear of the bearings. It is impossible to repair them - only change them. For an inexperienced repairman, this is a rather difficult task, because it may require sawing and subsequent gluing of a non-separable tank, behind which the bearing is located.

Therefore, if you are not confident in your skills, then do not take on this matter; it is better to call a specialist from the service center. But if your car's tank can be disassembled, then this task may be up to you. To do this, you need to remove the tank, then disassemble it by unscrewing the bolts and disconnecting the fastening latches.

The bearing must be removed using a special puller or hammer. We warn you that you need to use a hammer very carefully so as not to damage the parts.

After the bad bearing has already been removed, you should thoroughly clean the shaft, check whether it is worn, and then just install a new bearing.

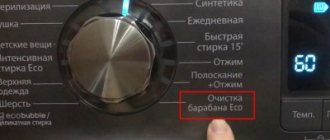

Control block

Characteristic symptoms of a malfunction:

- all buttons are lit;

- nothing turns on;

- the board error code is displayed;

- One of the elements does not receive 220 volts.

Electronic control module

Note that the module is a reliable part of a Samsung automatic washing machine. A breakdown occurs when there is a power surge both internally and externally. This can also be caused by incorrect connection.

You can partially protect yourself from external surges by unplugging it from the socket in standby mode!

An internal surge occurs due to damage to a peripheral device, usually: UBL, heating element or motor. In this case, we check everything. Repairing the control board yourself is not recommended. According to Western standards, the module is not repaired, but replaced. In Russian realities there are specialists who restore them.

Motor

Quite a reliable item. It is characterized by the following malfunctions:

- interturn closure;

- brush wear.

The first problem is caused by improper use, namely: constant overload of laundry. Another reason for the occurrence is frequent use during the day. You must understand that you bought a household machine, not an industrial machine. And it is designed for 2-3 washes per week. Repair of this fault is unlikely. We change the motor.

Washing machine motor

In the second case, simply change the consumables. This problem is inherent only to commutator motors. But in washing machines, in 80% of cases they are used. The procedure requires certain skills, but it can be done independently. Read more about replacing electric motor brushes.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

The service life depends on the intensity of use, and it can be estimated by the following period - 8-12 years.

UBL

Changing the lock is quite simple. Let's take a closer look:

- We open the hatch and pull off the metal clamp with a spring that secures the cuff to the body.

- We pull back the rubber at the location of the UBL and hold it from the inside with our hands.

- We unscrew the screws that secure the lock and pull it out.

- We pull out the chip with the wires.

- We install a new one.

- We tighten the cuff and clamp. Screw it on.

Burnt UBL

We check the operation of the SMA.

We have described typical malfunctions that can occur in washing machines. Most of them can be repaired with your own hands without calling a specialist. It's not always that simple. And if you cannot cope, or the breakdown is unclear, then contact a specialist.

Table of correspondence of spare parts to certain models.

Video

Hatch handle

Trivial breakdown. This is caused by improper use. Most inexpensive models are equipped with thermal plate locks. It is she who blocks the hook and prevents the hatch from opening during the washing period.

But after the end of the cycle, the plate needs time to cool down - 2-3 minutes. If you read the instructions carefully, it is written there. But people usually don’t wait and pull the handle. Since it is plastic, it breaks over time.

Handle in a disassembled hatch

Actions:

- remove the hatch;

- unscrew the screws in a circle;

- divide into halves;

- changing the hatch handle.

Important! Different repair kits for different models! We select by serial number!

Are you using citric acid?

Oh yes! No

Samsung washing machine error codes

It is much easier to determine damage if there is a display on the control panel. In case of malfunctions, symbols are displayed on it, each of which corresponds to a specific breakdown.

| Basic error codes | Corresponding fault |

| 4C | Water does not fill or fills too slowly (the filling process takes more than 20 minutes) |

| 4С2 | Make sure that the inlet hose is connected to the cold water pipe |

| A0,B0,C0,D0,E0 | Diagnostics of the washing machine is enabled (test mode, which is used at the factory) |

| 5C, 5E, E2 | Water does not drain |

| dC | Door is open |

| O.C. | Excess water, you should spin the machine and restart it |

| LC,LC1 | Problems with the inlet hose |

| Ub | Spin does not work |

| U.C. | No power supply, low voltage, check connection |

| 3C | Engine doesn't work |

| NS | The heating temperature has been exceeded; the thermostat may be faulty |

| 1C | The water level sensor is not working correctly |

| DDC,ddC | Appears if the Add Door (for loading forgotten laundry) is opened without pressing the Start or Pause button. |

| DC3 | Add Door lock does not work correctly |

| Sd | Too much foam |

| DC1 | The main door lock did not work correctly |

| Sun | The unit cannot start the engine |

| PoF | There was a power outage during the washing process |

| Hot | During the drying process, the temperature inside the drum exceeded 700C |

| LE,LC,E9 | Spontaneous drainage of water due to a low-lying hose or a leak. |

Please note that the listed fault codes are periodically modified and new ones are added. Therefore, before starting repair work, you should check the list of errors specified in the instructions.

Source

Drive belt

Over time, it “breaks apart” and tears. Overloading with laundry speeds up this process. Please note that the belt may stretch. In this case, it scrolls and washing will be impossible.

Replacement instructions:

- Remove the cover from the back, first unscrew the screws.

- Pull the belt towards you and at the same time rotate the pulley. We're filming.

- It's more difficult to install. First we put it on the motor shaft and hold it.

- With the other hand we place it on the pulley, twisting it at the same time.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! Select the belt exactly the same!

Belt pulley

Samsung washing machine device

Let's get acquainted with the structure of a washing machine using the example of the well-known Sensor Quick model. Main front elements of the model:

- removable front panel;

- distribution hopper for powder and special products;

- control Panel;

- electric valves;

- level relay;

- laundry tank;

- adjustable stand legs;

- drain pump with filter;

- drain hose;

- drain hose plug.

Rear elements:

- power cable;

- counterweights;

- tank suspension springs;

- shock absorber;

- engine;

- pulley with drive belt.

The control panel is a board with buttons and indications that turn on the washing mode, change the temperature, spin speed, washing time, and delay start. It is also possible to manually set all these parameters with the “Manual program setting” button. The display shows the current washing status and error codes.

Signs of trouble

You can understand that there is something wrong with the board based on the following signs.

- The washing machine does not spin things out; at the same time, the control panel freezes and does not respond to user actions at all; the error code is not displayed on the display.

- All the LEDs on the control panel blink in turn and all together, at the same time it is impossible to activate any washing program.

- The program for removing contaminants is installed and launched, at the same time, water either does not fill the tank, or the water is immediately drained on its own, besides, after this the machine “freezes”, and only reloading helps. Along with this, after the secondary start, washing can be done as usual.

- With any washing program, the machine runs for 3-4 hours in a row without stopping, without switching to rinsing and spinning. The drain pump makes no effort to pump water out of the tank. After a long period, the unit stops.

- After connecting, when trying to set up the dirt removal program, the machine freezes and turns off.

- The dirt removal program is installed, the washing process is shown on the display, but in practice nothing happens, water does not fill the tank, the drum does not rotate - nothing happens.

- The electric motor randomly often changes the speed of the drum despite the fact that the change in speed is not predetermined by the program. The drum rotates in turn and for quite a long time in one direction and then in the other.

- The thermoelectric heater of the washing machine either overheats the water or leaves it cold, neglecting the readings of the temperature sensor.