Error E10 usually occurs in Electrolux machines at the very beginning of the cycle. At the same time, the washer does not draw water. Rarely does the error come on before rinsing: in this case, washing proceeds normally, but during rinsing the machine does not fill with water and displays code E10.

What does the code that the Electrolux washing machine produces mean?

Problems with water entering the tank (the process is blocked or water enters the tank very slowly) are displayed on the display of the Electrolux washing machine with error E 10 (alternatively, code C1 may be displayed).

If the washing machine does not have a display, the error code is read by the blinking of the indicators located on the control panel.

There are several options for deciphering signals about a malfunction. For Electrolux washing machines with an EWM 1000 control module, the error code is read by two indicators, one of which is located near the “Start/Pause” button, and the second near the “Wash End” button.

The indicators flash alternately. The number of blinks of the first indicator corresponds to the number of the error code, the number of blinks of the second indicator corresponds to the second number of the code.

Models of Electrolux washing machines with an EWM 2000 control module are distinguished by a more complex scheme for recognizing error codes. To decrypt, use eight light bulbs located on the right side of the control panel. The four upper lights are responsible for the first digit of the code, the four lower lights for the second digit of the washing machine error code.

The serial number of the indicator is determined from top to bottom. In case of error E10, only the first of the top four indicators is lit.

You can find out exactly which control module is installed on a specific Electrolux washing machine on a plate attached to the body of the household appliance or by markings that can be seen on the back of the control panel.

Adviсe

Before starting repair work, you must make sure that the device is disconnected from the electricity , water supply and sewerage networks.

Provided that all components and mechanisms are in good working order, a reboot will help quickly resolve the E10 error in the Electrolux washing machine.

The household appliance must be unplugged, wait ten minutes, and then start the washing process again.

Possible reasons

In practice, there are many reasons that can lead to error E10. The SM can record an information code on the monitor in the following cases:

- in the absence of water in the general household water supply system, in other words, the cold water supply is turned off;

- if the water intake hose is damaged;

- when the filling valve fails;

- if the pressure switch is faulty.

In some cases, self-draining of water from the tank occurs, and spontaneous leakage of water from the tank of the washing machine occurs - it becomes the result of some serious internal failure. Some Electrolux machines of the latest models with an extensive coding database can clarify the reason for the suspension of the unit, indicating a specific malfunction in the operation of the entire system.

However, the vast majority of the company’s units do not have this option, so they are limited to the E10 information code. If the washing machine could not indicate a specific part that had failed, then when carrying out repair work you will have to keep in mind all of the listed factors.

How to fix it?

You need to start repair work with the most basic action - make sure that cold water enters the system. This is not difficult to do - you just need to open the bathroom or sink faucet and see if water flows from it. If everything is in order, then it’s worth checking to see if the valve where the inlet hose is attached is blocked - often equipment owners forget to open it before turning on the machine.

The issue of error E10 can also be affected by the water pressure - it should not be too weak. Owners of dachas and country houses often face a similar problem in the summer, when during irrigation hours all the neighbors turn on the water en masse. The pressure is noticeably reduced, this can lead to freezing of the working SM.

If there is a filter between the tap and the inlet hose, then you need to check it carefully - it may become clogged with sand or other impurities contained in the process water. A similar inspection should be carried out on the catch grid, which is located in the area where the hose enters the SM. It is possible that the blockage is located directly in the hose - then you need to disconnect it, carefully inspect it and make sure it is passable, that is, check whether it allows liquid to pass through.

Please note that any dirt plugs in the hose can only be removed under strong water pressure. The use of sharp wire and chemical reagents damages the integrity of the part.

Be sure to make sure that the collected liquid does not come out of the reservoir on its own. To do this, you need to lean towards the operating unit and listen. If you notice that water is bubbling in the drain, and then the unit displays error E10 and the operation of the machine is suspended, it means that you need to correct the situation and eliminate the self-draining. First, they look at the condition of the drain hose; it is probably twisted, jumped off, moved, or is below the permissible level. Under no circumstances should it pass along the floor; it should be raised by 50-70 cm.

There should be some air circulating in the hose, so do not lower it too deep into the drain.

If it is not technically possible to install the machine in strict accordance with the rules, then you should additionally resort to using a check valve; it will protect the machine from unauthorized draining. This part is quite inexpensive, and you can always install it yourself.

If the drainage is organized according to the requirements, and the liquid flows into the machine unhindered, but the volume of washing liquid is still not enough, most likely the breakdown concerns internal elements - the water level sensor, inlet valve or pressure switch. It is difficult to diagnose a pressure switch without basic skills and knowledge. To do this, you need to disconnect the washing machine from the electrical mains, turn off the tap responsible for supplying liquid to the tank and remove the top cover of the washing machine by unscrewing the screws holding it. Having carried out these steps, you will gain access to the sensor, then carefully press out the clamp holding it and moving it and disconnect the pressure hose.

To check the operation of the pressure switch, you will need a tube of the same diameter as the sensor fitting. It needs to be attached to the fitting and slightly blown. If the sensor is in good condition, you will hear 1 or 3 clicks - they indicate that the contacts have worked. After this, the pressure switch should be inspected for visible defects; if you notice dirt or debris inside the pipe, carefully rinse the part under running water.

To check the functionality of the pressure switch, a multimeter is usually used. This device is set to resistance mode and its probes are placed on the sensor contacts - the readings on the device monitor should change. If they remain the same, then the element is faulty and requires a complete replacement. Less commonly, the cause of the malfunction is the failure of the electronic module; problems with it are indicated by the following signs: water is being filled into the tank, the washing is running, but from time to time the unit pauses and displays error E10.

After turning the Start button off and on again, the program continues to work. This directly indicates problems with the electronics; they may be the result of improper factory assembly, unstable mains voltage parameters, or physical wear and tear.

This type of breakdown is considered one of the most serious and requires the involvement of a washing machine repair technician.

Let's check the tachometer

The first on the list for diagnostics is the tachogenerator. To check it and, if necessary, repair it, you must first find the device. There will be no problems with this: for all washing machines, regardless of the brand, model and year of manufacture, the Hall sensor is located in the same place - on the motor shaft. You can access the device in a simple way.

We disconnect the washing machine from the network, disconnect the drain and water supply hoses. Prepare screwdrivers and a multimeter. Unscrew the back panel of the case. Remove the drive belt. We find an electric motor. Pay attention to the small metal ring on the motor shaft - this is the Hall sensor.

- We mark the wiring connected to the engine or record all the phases on the camera, otherwise there is a high probability of making a mistake in the connection during reassembly and burning the motor.

- Unscrew the screws holding the engine.

- With both hands we swing the engine from side to side, after which we sharply remove it from the seat. You should be prepared for the fact that the part is very heavy.

As soon as the engine and tachogenerator are in your hands, you can begin diagnostics. First, we carry out a visual inspection: for the presence of external mechanical damage and the reliability of the fastenings. Often the clamps in the terminals become loose or the contacts come loose, and the solution to the problem is to restore the previous balance.

If visually everything is in order, then testing with a multimeter is necessary. There are two ways to carry out the test. In the first case, we set the device to measure Ohms, after which we release the contacts and attach the probes to the exposed contacts. Next, we evaluate the numbers on the display: if a value of 60-70 Ohms is displayed, then the sensor is working properly.

Another option is to measure the current generated by the tachogenerator. To do this, turn on the “Voltage” mode on the multimeter, apply the probes and accelerate the engine by hand. If a value within 0.2 Volt appears on the screen, then the Hall sensor is working. Otherwise, we replace the faulty device with a new one.

How to reset?

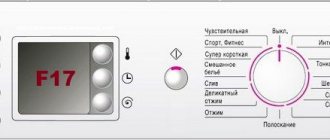

In order to reset the error code in a washing machine with a program selector, you need to simultaneously press the buttons as shown in the figure:

For washing machines without a selector, the error is reset by simultaneously pressing buttons 2,4 (see figure):

Call the master

For those who understand little about the workings of a washing machine, diagnosing the E10 error code can be a real problem. Service center technicians will help resolve the issue of restoring the functionality of household appliances.

In the instructions for the washing machine (on the last page) or on the Internet you can find contacts of the necessary specialists . When making a request to call a technician, you need to specify the model of the washing machine, year of manufacture, and describe the problem that has arisen in as much detail as possible. After the diagnostics have been carried out, the technician will be able to determine the full cost of repairing the washing machine.

Depending on the identified cause, eliminating the E10 error will cost from 1,700 to 2,500 rubles.

In what cases can you fix error E10 yourself?

Problems that can be solved on your own are usually not related to automation, but are caused by external factors. These are the ones that can be easily eliminated without the involvement of specialists:

- The lack of water or weak supply depends on the water pressure in the plumbing system. This may be due to its complete absence on the line (accident, planned maintenance, etc.). Possible low pressure due to large water intake by many users at the same time. Another reason (most often happens in metal water pipes) is corrosion of the inner surface of the pipe and a narrowing of the diameter of the watercourse. Having resolved the issue with water pressure, we deal with the E10 signal. The error is reset by disconnecting and reconnecting the washing machine to the network.

Please note! To avoid the error occurring again, you should wait until the water pressure required for the washing machine appears, and only then start washing.

- There may be no water in the machine if the tap through which it is supplied is closed. Another possible version of the same problem is that the valve is not fully open, and it flows very slowly. After fully opening the shut-off valve and restarting the washing process, the error is guaranteed to disappear if there are no other reasons interfering with the operation of the SMA.

- When an error appears, the washing machine may respond to a slow flow of water due to a squashed or bent hose. To ensure the free flow of water, it is necessary to check the condition of the flexible supply tube and, if necessary, free it from kinks, clamps, etc. Repeated turning off and on removes the problem with error E10.

- The filter mesh of the filler tap, designed to retain mechanical impurities from the water supply system, is clogged. Often, the absence of a coarse filter (usually installed in front of the water meter) leads to the mesh filter quickly becoming clogged and requiring periodic cleaning. It is better to replace it with a new one, since cleaning it with a needle or soaking it in a special solution to remove limescale is a long and labor-intensive task. After completing all the steps and turning on the washing machine again, the error should disappear.

Attention! Work on cleaning or replacing the filter mesh must be preceded by disconnecting from the network and turning off the tap.

- Self-draining water. This problem occurs due to improper connection of the drain hose to the sewer pipe. Their connection must be at a level of 60 cm or higher, otherwise, even with normal pressure, water will drain from the tank. The problem can be solved simply; for this purpose, an additional loop is created above the specified height, but not more than 100 cm. A plastic arc-shaped holder from the washing machine kit serves this purpose. You can purchase it separately or bend and secure the drain hose yourself. The error when turning on the machine to the network will go away if this was the reason.

On a note! If for some reason the hose cannot be secured according to the rules, purchase a return valve and install it on the drain. Its task is to prevent arbitrary water from leaving the washing chamber of the machine. It costs little and is easy to install.

- A one-time failure of the control module can cause an error code to appear on the display. The most common cause is power surges. Unplugging for a few minutes helps.

If the listed reasons for the appearance of the E10 signal have been checked, and the error is still displayed on the control panel, then the problem is not with them.

Possible faults requiring repair

In a situation where all possible cases of an error have been investigated, but the cause cannot be found, only one conclusion is possible: a breakdown of one of the mechanisms or devices of the washing machine. It is difficult to determine them on your own, so calling a specialist would be the most correct solution. In what cases can you not do without it:

- The control unit is damaged. Cause: burnt out circuit elements. Both repair and installation of a new module are possible;

- The water supply solenoid valve has failed. There may be two reasons: a blockage or a burnt out coil;

- breakdown of the level sensor (pressure switch), which most often gets stuck due to accumulated dirt. In such cases, it signals that the tank is empty. In another situation, overflow is possible due to the fact that the sensor did not send a “stop” signal to the control unit. There may also be problems with the hose connecting the sensor tube to the camera. The repair consists of cleaning the pressure measuring chamber from dirt deposits, replacing the supply hose or the level sensor itself with a new pressure switch.

All elements are working properly, but the error signal does not disappear

We figured out how to fix the problem. But sometimes a situation arises in which an error known to us can disrupt the operation of a washing machine for no reason. To be more precise, the problem still exists, but it is not related to the flow or drainage of fluid, and the units responsible for this function normally. It turns out that the machine is washing, but an alarm signal is displayed on the screen.

In this case, an experienced specialist will have to deal with this situation, since it is not recommended to dismantle and test the control unit module yourself if you do not have the appropriate skills for this.

Causes

Each of the error codes has a reason (and often more than one) for its occurrence. Thus, error code E11 usually occurs when one of the water inlet valves or its control circuit on the electronic controller breaks down. This is the most common, but not the only reason. Among others, there is insufficient resistance of the valve winding (the norm is 3.75 ohms), insufficient water pressure in the water pipes, and clogged water inlet path.

If problems arise with draining water (error code E21), it is worth checking the serviceability of the drain pump, the permeability of the filters, pipe and drain hose. It is the malfunctions and contamination of these elements and components of the machine that most often become the cause of this type of breakdown. It also makes sense to check the voltage of the drain pump winding (the norm is 170 Ohms). Finally, the cause of this type of error can also be a malfunction of the electronic controller.

Error EF1 may also be associated with exceeding the drain time, and the display of code EF2 indicates an increase in foaming, the root cause of which is also a clogged drain line. In this case, the origins of the problem are sought in the drain hose or sewer; it makes sense to check the filter above the drain pump for clogging.

The causes of failure of the pressure switch are mainly caused by clogging of the tube, malfunctions in the electrical network, and failures in program settings. The pressure switch is responsible for the overall performance of the washing machine, otherwise it is called a water sensor and a voltage sensor. That is why the failure of this element leads to the appearance of completely different “symptoms” - premature start of washing, inability to activate the laundry spin function.

The causes of errors E40-E43 are related to the hatch door not being tightly closed. This could be due to debris or foreign objects getting into the lock. That is, the search for the cause of the malfunction begins precisely from this zone. If everything is in order with the lock, then the cause of these error codes may be a misalignment of the door. That is, the screws in the bolts have become loose, the door has “slipped”, so it is impossible to close it correctly. It is clear that in this case you should tighten the bolts with a screwdriver and return the door to the desired position.

Sometimes the reason for a door that is not tightly closed may be hidden in voltage surges. You can check this in a simple way - unplug the washing machine from the power supply for 10-15 seconds, and then turn it on again. As an option, try manually pressing the door to the hatch with your hands and wait to see if a characteristic click is heard and a lock icon appears on the display.

Finally, the cause of the door not closing tightly can be wear and tear on the machine parts. On average, they are all designed for a 5-year service life. Problems with the operation of the electric motor can be identified by the appearance of error E50 on the display. Moreover, the cause of its occurrence may be a malfunction of the relay, bearings, or lack of a signal from the tachogenerator.

The reasons for this are also different - from a washer that has slipped off the thread to serious malfunctions of the tachogenerator and its natural wear.

One of the weak points of washing machines is the heating element. One of the common causes of heating element failure is the formation of scale on its surface. Scale does not allow heat to pass through, that is, the heating element begins to overheat, and the heating of water during washing turns out to be insufficient.

The formation of scale is usually associated with high levels of water hardness, the presence of foreign impurities in it, primarily calcium and magnesium salts (this is why deep cleaning filters for water pipes are recommended for use), and too aggressive detergents.

Sometimes the heating element, on the contrary, heats the water too quickly and too much. In this case, the temperature sensor is to blame and should be replaced. The relays that control the functioning of the heating element may also fail.

Error codes for Electrolux washing machines (description of codes)

The Electrolux company produces a wide range of washing machines. Each model has its own characteristics, which the owner of the equipment must familiarize himself with before carrying out repairs. The instructions that are given to the consumer upon purchase can help with this.

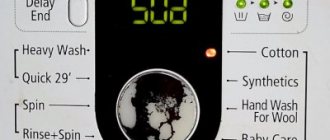

With modern SMs equipped with a display, everything is simple - an alphanumeric error code is displayed.

Zanussi, LG, Electrolux - any of these popular cars has its weaknesses. Such technical weaknesses lead to typical breakdowns. How to determine what the problem is?

Thanks to the self-diagnosis system, owners can find out about the causes of the malfunction without calling a technician to their home.

Almost all modern Electrolux models are equipped with a digital display. It is much easier for owners of such equipment to detect a breakdown. The equipment independently diagnoses its components and displays the result - an error code.

If your Electrolux washing machine suddenly stops working and an unknown code appears on its display, you should not immediately look for a technician and service center numbers.

Knowing the error codes of Electrolux washing machines, you can quickly identify the weak point and eliminate the problem. The code looks like: E11, E13, E24, E94, etc. Each of them hides certain information. There are many error codes. This article will discuss the most common ones.

E20

The most common malfunction is a breakdown of the drain system. It will appear on the display as “E20”. This code occurs when the equipment does not drain the water. In rare cases, it appears due to a malfunction of the electronic module. The signal about an empty tank simply does not reach the module. The cause of E20 may be: a breakdown of the level sensor, a malfunction of the drain pump, or a blockage.

With this error, there may be a blockage in the drain system.

E10

Code E10 may appear on the display at the beginning of the wash. It signals slow water supply or no water supply at all. The reasons can be different: from the most banal to the serious. The first is the lack of water in the tap, the clamping of the inlet hose. Sometimes users simply forget to open the shut-off valve. More serious causes of error E10: clogged filter, incorrect installation of equipment, failure of the control module.

The reason for this error may be a simple lack of pressure in the water supply.

E40

Electrolux washing machines issue error E40 less often. This indicates a broken door lock. Determining the cause of the malfunction is quite simple. You need to enter diagnostic mode (you can see how to do this in the instructions). Then the unit will clarify the problem. One of the codes will appear on the display: E41 (the door is not hermetically closed), E42 (the locking device is broken), E43 (the triac is broken), E44 (the door sensor is broken), E45 (the electrical circuit has become unusable).

It is necessary to check the rubber cuff and the lock to see if foreign objects have gotten into it (coins from pockets often get in).Other errors

Other common mistakes include:

- E13 – violation of the tightness of the entire system of the unit;

- E35 – too much water in the drum;

- E3A – heater protective relay is broken.

If it is impossible to repair it yourself, you must contact a service center.

Elimination

So, one of the common problems is the absence of signals on the display when the machine is connected to the network. Simply put, she does not react in any way to such actions. First of all, you should check whether there is electricity in the network - plug in other equipment into the outlet.

You can try to reset the washing program and enter it again.

If everything is ok, check the power cord and plug. If damage is found, do not isolate, but replace. The cause may also be oxidation of the control panel contacts or burnout of the surge protector or its elements. Troubleshooting this type of problem begins with removing the top cover (just unscrew the bolts). You will see the filter against the wall. When it burns out, swelling will be noticeable. In this case, the filter must be replaced. To check the keys, you must first remove the tray, after which the buttons will be visible (behind the module).

In case of contact oxidation, the element is replaced.

If there are problems with water intake and drainage, the first thing to do is close the shut-off valve and unscrew the hose from the housing. A filter will be found behind it; it is removed and washed under water; the same should be done with a hose. It makes sense to immediately dismantle the back cover and check the inlet valve located behind it with a multimeter (the norm is 2-4 Ohms).

If there is water left in the tank, you should also clean the drain. You can find it behind the door located at the bottom of the machine (from the front). When you open this door, you will see a filter that needs to be unscrewed. Attention, at this moment water will flow out of the hole, so you should immediately prepare rags and buckets. After unscrewing the filter, it is washed, as well as the space that it covers.

It is worth wiping the filter dry and screwing it back in.

If the drum begins to wring out clothes poorly, and the machine vibrates strongly, you should check the tension of the drive belt. To do this, you need to unscrew the back panel of the device. If the belt comes off, you will immediately see it; just return it to its place (on the engine pulley). When the belt wears out, it must be replaced. In machines with a classic engine, brushes may need to be replaced. You need to check their graphite rods (remove them from the case, disconnecting the contacts).

If more than half of the brushes are worn, they must be replaced.

What does the code that the Electrolux washing machine produces mean?

Error code E20 appears in Electrolux washing machines if draining water from the tank continues for more than 10 minutes.

This may be due to malfunctions of the following parts:

- drain hose and sewer;

- drain pump (pump);

- filter, which is located in front of the pump;

- corrugated pipe between the tank and the pump;

- water level sensor (pressostat);

- an electronic control unit (ECU), which reads the sensor signals and starts the pump.

As a rule, during the washing process the user sees only code E20. You can more accurately determine the location of the breakdown using the diagnostic (test) mode.

To enable this function, you need to hold down the “Start” button and the one closest to it, and then switch the program selector to one of the positions. The drain and spin test is carried out in the eighth position of the handle.

After starting the diagnostics, another code may appear on the display: E21, E23 or E24. There are separate codes to indicate breakdowns of the pressure switch (E31-E35, E38), so error E20 most often indicates problems with other components of the drain system.

In automatic washing machines (CMA) without a display, the code is displayed using special indicators, which are located on the right side of the front panel. The eight light bulbs are divided into 2 groups: upper and lower. You can determine the error code using the number of the lit indicator in the group.

Indication of drain system errors on SMA without display:

| Indicator | E20 | E21 | E23 | E24 |

| Upper | ||||

| №1 | — | — | — | — |

| №2 | + | + | + | + |

| №3 | — | — | — | — |

| №4 | — | — | — | — |

| Lower | ||||

| №1 | — | + | + | — |

| №2 | — | — | + | — |

| №3 | — | — | — | + |

| №4 | — | — | — | — |

In older models with an EMW1000 series control module, the error code can be determined by the number of flashes of the two indicators located near the Start button.

Failures associated with water entering the drum

Problems in the operation of units associated with the lack of water in the tank are common among Electrolux models - for example, such as the W4180H. Given that the quality of tap water leaves much to be desired, large amounts of sediment can often be observed deposited in hoses, filters and drain pumps. This makes it difficult or stops transporting water into or out of the tank.

Error E10 in Electrolux washing machines is one of the most common

Error E10 in Electrolux washing machines, as well as E11 in some models, indicates that there are certain problems with the intake of liquid into the drum: water does not flow or its pressure is so low that the level does not reach the optimal level in the allotted time.

During diagnostics, the pressure in the inlet line through which the liquid flows is checked. Often the water in our houses is turned off or the owners turn it off themselves and then forget to turn it on. Therefore, such reasons are quite common. In addition, the inlet hose and filter are checked for clogging.

The intake valve may not open due to the lack of a control signal or due to a broken winding in the electromagnet (possible error EC1). You can check the winding with a multimeter - if it is working properly, the device should show a resistance in the range of 3.6–3.8 kOhm. The electronic control unit (hereinafter also referred to as ECU) contains symmetrical thyristors - triacs (hereinafter also referred to as triacs) that control the valves. If there is a malfunction in this unit, water will not flow into the tank.

All of the above breakdowns can be eliminated by cleaning the intake manifold and clogged parts or replacing faulty elements.

Causes, diagnosis and solutions

The causes of a malfunction of the drain system can be:

- Mechanical blockage of the hose, filter, internal pipe, pump or sewer.

- Kink in the drain hose.

- Damage to the pump impeller due to a foreign object.

- Failure or manufacturing defect of the pump's electrical system.

- Disconnection, destruction or oxidation of the contacts of the pump and the electronic unit.

- Combustion of tracks and radio elements on the ECU board.

The appearance of code E20 on the display does not always indicate a critical breakdown. It can occur due to a one-time malfunction of the electronic module or a slight blockage that can be eliminated within 1-2 minutes.

When error E20 appears, you must:

- disconnect the SMA from the power supply for 10-15 minutes;

- inspect the drain hose for kinks;

- remove it from the sewer pipe, place it in a large basin or sink;

- start the drain program.

If the error occurs again, you must turn off the unit and begin diagnostics. If the water is draining normally, you should check the permeability of the sewer and install the hose in place.

Clogged drain filter, pipe or hose

A clog in the drain system is one of the easiest SMA problems to fix. To restore the operation of the unit, you must:

- Turn off the washing machine.

- Remove the bottom panel on the front of the unit, behind which is the drain filter.

- Cover the floor under the filter with an absorbent cloth and place a wide, low container. Turn the handle and remove the part.

- After removing water from the tank, disconnect the drain hose and check it for blockages using a stream of running water.

- Inspect and wash the filter. Use your fingers to clean the seat.

On Electrolux top-loading models, the drain filter is accessed through the tank, so you need to remove the laundry before draining the water.

To check the pipe, you will need to partially disassemble the washing machine. This part is secured with clamps at the outlet of the tank and the inlet of the drain pump.

Drain pump failure

If the drain is not blocked, then the problem may be a faulty pump. Error E20 can appear in several cases:

- the pump impeller is jammed with a small object;

- one or more pump blades are broken;

- the pump electric motor burned out;

- The pump contacts have oxidized or become disconnected.

To check and repair the pump, you will need to disassemble the SMA and disconnect the wires and hoses. After this, you need to dismantle the pump, examine the impeller and check the resistance at the contacts with a multimeter (nominal value is about 170 Ohms).

A breakdown of the pump motor can be determined by the absence of a characteristic hum at the beginning of the drain. If the motor or impeller is broken, the sump pump will need to be completely replaced. In other cases, the part is repairable.

Electronic unit malfunction

If, if the pump is clogged or malfunctioning, only errors E20 and E21 appear on the display, then if there is a problem with the computer, codes E23 and E24 may also appear.

Problems with draining water may occur due to the following failures of the electronic module:

- broken wires or oxidation of contacts (E20, E24);

- module firmware failure (E20, E21);

- breakdown of the pump control triac (E23);

- defective pump control circuit on the board (E24).

To restore the operation of the SMA, the technician checks the functionality of the radio elements, cleans and solders the defective tracks, and, if necessary, reprograms the board. If a large number of tracks or the processor is damaged, a complete replacement of the module is necessary.

What is this code that the Electrolux washing machine produces?

The Electrolux washing machine signals problems with the hatch locking with error E40. There are many reasons why the seal of the hatch closure is broken. Deciphering the E40 information code helps to more accurately determine what exactly caused the malfunction.

To enter the diagnostic mode of the Electrolux washing machine without a software selector (the washing mode is selected by pressing individual buttons), you must simultaneously press and hold two buttons in the right corner of the control panel (pictured item 1) and one large round button located on the right sides (pictured item 2).

As soon as all the indicators flash simultaneously (a signal that entry into the diagnostic system was successful), a code will appear on the display that pinpoints the cause of the washing machine malfunction:

- E41 - the hatch door is not tightly closed;

- E41 - the hatch locking device has failed;

- E43 - the triac responsible for the operation of the UBL has failed (additional diagnostics of the control module is required);

- E44 - the hatch door opening sensor is faulty;

- E45 - break in the eclectic circuit between the triac and UBL.

For models of washing machines with a program selector (the washing mode is selected by turning the knob of a special switch), to enter the diagnostic system, you must press and hold the two outermost buttons on the right side of the control panel (item 2 in the photo).

In Electrolux washing machines without a display, problems associated with locking the hatch door are indicated by flashing indicators.

In models with the EWM 1000 control module, the code is transmitted by two indicators: one located near the “Start/Pause” button, the second - near the “Wash End” button. The indicators flash in turn, with a short pause. The number of flashes determines the two-digit value of the fault code. In the specific case of error E40, the indicators flash once four times.

For washing machine models with an EWM 2000 control module, error code recognition is carried out in a slightly different way. To obtain the necessary information, count the number of blinks of the eight indicators located on the right side of the control panel. The number of blinks of the four upper indicators is the first digit of the error code, the number of blinks of the second four indicators is the second digit of the code.

For a specific error E40, only the third indicator out of the top four blinks four times. The serial numbers of indicators are determined from bottom to top.

Why does it appear and what to do?

The process of eliminating error E40 of the Electrolux washing machine is carried out according to a clearly defined algorithm, starting with the simplest actions, gradually moving towards more complex repairs that require certain knowledge and training.

Checking the tightness of the hatch door

The first thing you need to do when the washing machine signals a malfunction with error E40 is to open the door, check the rubber seal of the hatch for stuck debris, and close the hatch door again (press until it clicks).

Additionally, check the condition of the hinges (door misalignment can also trigger error E40). It is enough to tighten the fasteners that have become loose over time so that the hatch door fits hermetically to the body of the washing machine again.

Testing and changing the hatch locking device (UBL)

The absence of a characteristic click when closing the hatch doors is a signal that the possible cause of the E40 error lies in a malfunction of the hatch locking device (UBL).

Algorithm of actions:

- Open the hatch of the washing machine.

- Using a flat screwdriver, carefully pry it off and tighten the metal ring (clamp) holding the rubber seal of the hatch inlet.

- Having bent the cuff, using a Phillips screwdriver or a tool with an asterisk attachment, we unscrew the fasteners holding the UBL.

- By pulling the lock to the left, carefully remove it from its seat.

- We check the dismantled lock with a tester. To do this, switch the multimeter to the “Resistance” mode. We apply one probe to the neutral contact, the second to the phase. The tester changes the readings - the UBL is working.

- We apply the tester probe to the neutral and common contact. If “0” is displayed on the multimeter display, the UBL is faulty and requires replacement.

- We disconnect the faulty lock from the wiring and connect a new part in its place.

After replacing the lock, return the clamp and rubber cuff to their original place, and run a test wash.

We eliminate contact breaks between the UBL and the control module

Very strong vibration of the washing machine, long-term operation of the household appliance in a damp room leads to disruption of the integrity of the contacts between the hatch locking device and the control module. In addition to error E40, a similar problem is indicated by a burning smell that occurs when starting the wash.

To troubleshoot the problem you must:

- carefully inspect the UBL contacts for breaks, burnt areas (additionally, the wiring is tested with a multimeter);

- clean damaged areas, solder breaks.

Before starting work, you must make sure that the washing machine is disconnected from the power supply.

Restoring the operation of the control module

Very often, error code E40 (in diagnostic mode E43, E45) indicates that the reason for the lack of locking of the hatch doors lies in the control module. Sudden voltage surges or moisture entering the washing machine body lead to burnout of elements in the UBL circuit.

To diagnose and fix the problem, you must:

- Remove the cover of the washing machine (unscrew the rear panel bolts).

- Remove the powder receptacle, unscrew the fasteners in the opened niche, and remove the control panel from the latches.

- Having carefully examined the control module, determine the burnt-out elements (damaged areas are distinguished by black color, convex capacitor caps), and resolder the necessary areas.

In the absence of knowledge, experience and skills in repairing the control module, it is better to entrust such work to the professionals of the service center.