The word “soda” refers to several complex chemical substances. Food, drinking, sodium bicarbonate, chemical formula NaHCO3, acidic sodium salt of carbonic acid. Calcined, linen, sodium carbonate, chemical formula Na2CO3, sodium salt of carbonic acid.

Caustic, sodium hydroxide, chemical formula NaOH. There are also some technical types of soda - crystalline hydrates containing sodium carbonate, and various brands of caustic soda. The above compounds have different properties and chemical formulas. But they all dissolve well in water, and their solutions have a more or less pronounced alkaline reaction. Let's take a closer look at them.

What is crystal soda

Crystalline soda is a mineral substance consisting of sodium carbonate molecules Na2CO3, NaHCO3. In nature, soda exists in three main forms:

- Food grade - sodium bicarbonate NaHCO3, which is a fine white powder without a specific odor. From an electrolytic point of view, a substance has an ionic crystal lattice, so it is depicted as an ion pair:

- Caustic - alkali NaOH (caustic soda), is a large white crystal.

- Calcinate is sodium carbonate Na2CO3, exists in the form of large white crystals.

From a chemical point of view, the formula of crystalline soda is defined as crystalline hydrate Na2CO3 * 10H2O.

Indications for use

Sodium bicarbonate is prescribed for poisoning, infections, to relieve an attack of heartburn, and for the symptomatic treatment of cough.

A solution of baking soda is used locally to rinse the mouth, throat, eyes, soften ear plugs, and as a compress to relieve itching after insect bites.

Also, products with sodium carbonate are indicated for people with problem skin: it can reduce the number of rashes and remove redness.

Chemical properties

Sodium bicarbonate - NaHCO3 (molar mass M = 84 g/mol)

The chemical properties of baking soda include:

- good solubility in water (9.59 g / 100 g of water), in which the aqueous solution is called a buffer solution (the concentration of the substance does not affect the pH value);

- interacts with strong acids to form new salts;

- at high temperatures (from 60 ° C) it decomposes with the formation of CO2, H2O, Na2CO3.

Baking soda is used in baking

Caustic soda - NaOH (Molar mass M = 40 g/mol)

The chemical properties of sodium hydroxide include:

- Interaction with acids through a neutralization reaction with the formation of salts.

- Interaction with acid oxides.

- It dissolves completely in water, releasing a lot of heat (a highly exothermic reaction).

Sodium carbon - Na2CO3 (Molar mass M = 106 g/mol)

The chemical properties of soda ash include:

- insoluble in acetone, carbon disulfide, ethanol; good solubility in glycerin and water raw materials;

- it reacts with stronger acids to form salts, CO2, H2O, since carbonic acid does not exist in free form.

How does sodium carbonate affect the human body?

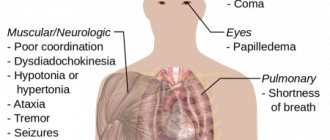

According to official data, the described compound belongs to the safe category of food additives. When used correctly, the substance is not capable of harming humans. However, individual reactions to the reagent should be taken into account. People with hypersensitivity may experience such manifestations as impaired respiratory function, fainting, allergic reactions, malfunctions of the liver, and brain activity.

Beneficial properties of sodium carbonate

In this case we will talk about baking soda.

The positive properties of the described substance include the ability to neutralize the increased acidity of gastric juice, due to which it is used to eliminate pain caused by gastritis and peptic ulcers. The ability of sodium carbonate to neutralize acids has ensured its widespread use in acid poisoning.

In addition, sodium carbonate is able to thin sputum, which is why it is often used in mucolytics used for respiratory diseases. It helps thin mucus and reduce cough.

Soda solution is also used to rinse the mouth, relieve pain from insect bites and skin damage, as an antiseptic and antifungal agent.

In cosmetology, a scrub based on sodium bicarbonate gives good results.

What is baking soda made from?

Baking soda, also known as baking soda or baking soda, is a white powder made up of small crystals that has a characteristic salty taste and dissolves easily in water. All of them are familiar and used in cooking, medicine, pharmaceuticals, chemical and light industries, and for household needs.

Baking soda is identified on food labels as E500.

Soda can be obtained in two ways: dry and wet. The process is based on saturating a heated sodium carbonate solution with carbon dioxide under pressure.

When wet, soda ash is dissolved in water, and when dry, baking soda is used. The finished bicarbonate is precipitated, and the separated liquid is reused.

Another technology is based on a saturated saline solution, which reacts with ammonia. The resulting compound is treated with carbon dioxide. Baking soda is formed and heated to form baking soda.

Absolutely harmless, non-toxic, explosive and fireproof. Has a slight irritant effect on mucous surfaces. Supplied in paper bags and plastic bags of various packaging.

Type of food additive, hazard and toxicity class, storage conditions

The following compounds fall into this category:

- sodium carbonate E 500(i);

- sodium bicarbonate E 500(ii);

- mixture of sodium carbonate and hydrogen carbonate E 500(iii).

The purpose of additives of this type is to facilitate the technological process of food production.

The described compounds belong to hazard class 3 and are non-toxic. Soda is highly hygroscopic, so it is important to store it in a hermetically sealed container in a dry place. After opening the package, it is recommended to limit contact with moist air and water.

Liquor.

The name "alkali" (K2CO3, Na2CO3, NaOH) was given to the products obtained by leaching wood ash. It contains about 70% potassium carbonate (potash), which is mainly used in the production of soap and glass. Sodium carbonate (soda ash) is the main component of some vegetable ash (salmon). When treated with slaked lime (calcium hydroxide), sodium carbonate is converted into caustic soda (sodium hydroxide), which is used for domestic and industrial purposes under the name "lye" or "caustic soda."

Production of soda ash.

Along with mineral acids and fertilizers, the most important products of the basic chemical industry are soda-based products: sodium carbonate, caustic soda and sodium bicarbonate.

Sodium carbonate is widely used in many industries, as well as for domestic needs. Up to 25% of sodium carbonate is used in the chemical industry to produce sodium bicarbonate, caustic soda and other sodium salts, glass, aniline and paint and varnish industries. The main consumers of soda ash are non-ferrous and ferrous metallurgy, oil, food, pulp and paper, textile and other industries.

Sodium carbonate - Ka2CO3 - is a white crystalline powder with a melting point of 852 ° C, density 2533 kg/m3. The bulk density of sodium carbonate ranges from 500 to 700 kg/m3. A special type of soda is also produced - the so-called “heavy” soda. The apparent density of “heavy” soda is from 800 to 1000 kg/m3. Sodium carbonate is a hygroscopic salt. It dissolves well in water, releasing heat. When the solution is heated above 32.5 °C, the solubility of soda decreases.

The quality of soda ash from nepheline raw materials is determined by the requirements of GOST 10680-70.

Methods for producing soda. Sodium carbonate is produced in three ways: ammonia, from natural soda and by complex processing of nepheline. In our country, the ammonia method is the main one. The process of processing nepheline for the production of alumina, soda products (soda and potash) and cement based on the apatite-nepheline deposit of the Kola Peninsula, as well as nepheline minerals in Siberia, is gradually becoming increasingly important. In some foreign countries, soda ash is obtained from natural soda.

In the total production volume, the share of synthetic soda produced by the ammonia method is 84%, and from nepheline - 16%. Capacities for the production of ammonia soda are used at 95-100%, nepheline soda at 85-95%.

PRODUCTION OF SODA USING THE AMMONIA METHOD

Raw materials.

The main raw materials for the production of soda ash are gypsum or limestone and sodium chloride solution. In addition, a number of auxiliary materials are used - ammonia, water, steam and electricity.

Carbonate raw materials. To produce carbon monoxide (IV) and lime, soda plants use limestone or gypsum, called carbonate feedstock. The normal operation of a soda plant largely depends on the quality of carbonate raw materials. The use of limestone is more desirable than the use of chalk. With increasing humidity of gypsum, fuel consumption for its combustion increases and, as a consequence, air consumption for fuel combustion increases. With increasing air flow, the concentration of CO2 in the flue gas decreases. In addition, the strength of gypsum is lower than that of limestone. The CaCO3 content in limestone according to OST 21-27-76 in terms of dry product must be at least 92%. The consumption of carbonate raw materials (100% CaCO3) per 1 ton of soda is 1.1-1.25 tons. Soda plants are usually located near deposits of carbonate raw materials.

Table salt is widely distributed in nature both in solid form and in the form of solutions. When producing soda using the ammonia method, it is not solid salt that is used, but brine, the cost of extracting which by leaching the salt is many times lower than the cost of extracting solid salt. At soda factories, the brine has the following requirements: it must be saturated or close to saturated. The maximum concentration of NaCl in water at 15 °C is 317 g/l.

In the soda industry, the concentration of solutions is usually expressed in so-called normal divisions (nd). Normal division corresponds to the content of 1/20 equivalent of substances in 1 liter of solution. In practice, a brine containing 305-310 g/l NaCl is used, which corresponds to 104.3-106.0 N e. An increase in the concentration of NaCl has a beneficial effect on the degree of its use, which leads to a decrease in the specific consumption of brine, a decrease in the consumption of ammonia, limestone, steam, water and electricity per 1 ton of soft drink.

To produce 1 ton of sodium carbonate, about 1.5 tons of sodium chloride are required.

Ammonia in soda production operates in a closed cycle: after regeneration in the distillation section, it is returned to production. To compensate for the inevitable losses, ammonia water containing up to 25% NH3 is introduced into the cycle. Ammonia water from coke ovens contains ammonium sulfide, which protects steel equipment and pipelines from corrosion. When using synthetic ammonia water, Na2S is introduced into the soda production process along with ammonia water.

General production scheme.

The complex soda production process can be divided into several stages (so-called stations or departments):

1) preliminary purification of the brine from calcium and magnesium salts;

2) absorption - saturation of the brine with ammonia and partially carbon monoxide (IV) to obtain ammonia brine;

3) carbonization - saturation of ammonia brine with carbon monoxide (IV) with the formation of sodium bicarbonate in the form of a suspension;

4) filtration - separation of a suspension of sodium bicarbonate from the filter liquid;

5) distillation - regeneration of ammonia and carbon monoxide (IV) from the filter liquid;

6) calcination (calcination) - decomposition of sodium bicarbonate into sodium carbonate (soda ash), water and carbon monoxide (IV).

In addition to the main processes in the production of soda, there are a number of side processes that are not directly related to the production of soda. Ammonia is reduced from ammonium chloride by treating the solution with lime milk:

2NH4СL + Ca (OH) 2 = 2NH3 + 2H20 + CaCl2

In the distillation section, the resulting ammonia is extracted from the solution by steam and sent to the absorption section. Calcium chloride solution is a waste product.

To obtain lime milk, lime CaO is required, which is obtained in soda factories by firing carbonate raw materials (gypsum or limestone) in lime kilns at a temperature of 1100-1200 ° C. Carbon monoxide (IV) is used, which is formed during roasting during the carbonization process, and lime CaO is quenched with excess water to obtain lime milk:

CaO + H2O = Ca (OH) 2

Thus, the production of soda using the ammonia method can be represented in the form of a diagram showing the relationship between the individual stages of the process:

In Fig. Figure 1 shows a general technological scheme for the production of soda ash using the ammonia method.

An aqueous solution of sodium chloride containing 305-310 g/l, previously purified from calcium and magnesium salts, flows by gravity into washer 1, where it absorbs carbon monoxide (IV) from the gases coming out of the carbonization column 7, and ammonia from the carbonization gases. from vacuum filters 5. After absorbing CO2 and NH3, the exhaust gases are released into the atmosphere. From gas purifier 1, the brine enters absorber 2 to absorb ammonia and carbon monoxide (IV) contained in the gases of distillation column 3. Gases not absorbed by absorber 2 are sent to washer 1 using a vacuum pump. Ammonite brine, pre-cooled in refrigerator 6, continuously enters the carbonization column 7, filling it almost to the top. Pre-washed and purified lime kiln gas 10 (37–40% CO2) and mixed gas (a mixture of lime kiln gas and soda kiln gas) are also supplied. The mixed gas contains 60-80% CO2 - with two gas injections into the carbonation column - and about 50% CO2 - with one injection. Gases are supplied to column 7 using compressors 8 and 12.

Rice. 1. Technological scheme for producing sodium carbonate using the ammonia method:

1 gas washing machine; 2-absorber; 3-distillation, 4-mixer; 5 - vacuum filter; 6 - refrigerator for ammonia brine; 7 - carbonization column; 8, 12 - compressors; 9 — refrigerator gas purifier; 10 - lime kiln; 11- devices for extinguishing lime; 13 - washing machine-refrigerator, 14 - soda oven.

The main reaction of the formation of sodium bicarbonate occurs in the carbonization column 7. A suspension of crystalline sodium bicarbonate in a solution of ammonium chloride and unreacted sodium chloride is sent to a vacuum filter 5 to separate sodium bicarbonate. The mother liquor containing ammonium carbonate and ammonium chloride (filtered) is fed by vacuum filters into the distillation column 3, where ammonia is regenerated from the solution containing ammonium chloride and ammonium carbonate. When the solution is heated to 70–80 °C, ammonium carbonate decomposes; The decomposition of ammonium chloride is carried out in the distiller-mixer 4, from where it comes from column 3.

Lime milk is also supplied here, obtained by removing lime in device 11. Regenerated ammonia and carbon monoxide (IV) are separated from the solution by water vapor supplied to the bottom of device 4 and enter absorber 2 for absorption from the brine. After the ammonia is removed, the resulting solution mainly contains calcium chloride and unreacted sodium chloride. This solution, called distillation liquid, is a waste product.

The NaHCO3 precipitate is washed on a vacuum filter 5 and fed into a rotating soda furnace 14 for calcination to form soda, water vapor and carbon monoxide (IV). Soda ash from furnace 14 goes to the warehouse and then to packaging.

Chemical parameters of crystalline soda

If we consider sodium bicarbonate as a crystalline hydrate, its physicochemical properties, as well as its structure, directly depend on temperature. Going from 32°C to 35°C will cause irreversible deformation of the molecule's structure:

Na2CO3 * 10H2O → Na2CO3 * 7H2O → Na2CO3 * H2O

The main physical and chemical indicators of the substance include:

| Parameter | Na2CO3 * 10H2O | Na2CO3 |

| Melting point, ° C | 32 | 852 |

| Density of the substance, g/cm3 | 1,446 | 2,53 |

| Heat capacity, J/mol * K | – | 109,2 |

| Solubility | H2O | glycerin H2O |

Recommendations for use

In everyday life, calcium carbonate is still one of the most popular substances. This is due not only to its cleaning properties, but also to the low cost of the product, which, moreover, can be produced regardless of the available bicarbonate.

Application cases:

- To restore a clean tile surface, dissolve 60g of sodium carbonate crystals in a liter of lukewarm water. Dip the hard cup and remove the dirt. Residues are removed with a clean damp cloth.

- If necessary, it is easy to independently prepare a good composition for washing and degreasing dishes. You need to measure out 3 tablespoons of homemade soda. Dilute it with a liter of warm water. Kitchen utensils washed with the product are rinsed well with running water.

- To clean the stove, add soda ash to 200 ml of warm water - 1 tbsp. L. Add detergent and silicate glue - 1 hour each. Mix until smooth. Spread on contaminated surfaces. After 15 minutes, clean with a damp sponge.

- To properly wash plumbing items, laundry soap is ground into shavings. To do this, use a grater or a sharp knife. Mix in equal volumes with sodium carbonate. By adding water, the mixture is brought to the consistency of a paste. Distribute evenly over the surface to be cleaned. After an hour, wash off with clean water.

- A simple method will help restore the whiteness of an enamel bath. First, dampen a soft cloth with vinegar (9%) and wipe all interior surfaces. After 10 minutes, soda ash is poured out in a thin, even layer. They are cleaned with a brush, then the remaining product is washed off with cold water.

Application of the substance

Thanks to scientific research, many ways to use crystalline soda have been discovered, and therefore this substance can rightfully be called a universal remedy. Soda is most widely used in the industrial sphere, in everyday life and cooking, in medicine and cosmetology.

The industrial sector gives its preference to caustic soda, where this substance is used for the following purposes:

- to make fabrics clean;

- for the production of paper and cardboard;

- for purification of petroleum products and production of oil products;

- to neutralize poisonous gases;

- to strengthen the foundation of buildings under construction;

- for cleaning equipment of industrial enterprises;

- for degreasing instruments;

- for creating cosmetics.

Any type of crystalline soda is a traditional remedy used at home as a cleaner for various types of contaminants. So, with the help of this substance you can remove stains from tiles, sinks, plumbing fixtures, dishes or carpets. Some modern powders can destroy the surface of linoleum, marble, and sinks made of artificial stone with their aggressive effects, but this phenomenon does not apply to crystalline soda.

In addition, you can easily get rid of scale on the heating elements of your washing machine, and in this case, soda ash is most suitable. Eliminate blockages in sewer pipes, get rid of unpleasant odors in the refrigerator, whiten bed linen - all these are problems that can also be solved by crystalline soda, which is a real assistant to every housewife.

Read also: Increased eye pressure: symptoms and treatment with folk remedies

In the field of cosmetology, baking soda is mainly used; its use allows solving the following problems:

- lose extra pounds;

- eliminate dead skin cells;

- eliminate pimples and acne;

- get rid of puffiness under the eyes: remove oily shine from the face, reduce oily hair.

In addition, you can treat makeup or manicure tools with a soda solution - this will not only clean them of dirt, but also remove germs from surfaces.

Due to its ability to have a destructive effect on bacteria and pathogenic microorganisms, soda is used in medicine to treat various diseases caused by such pathogens, but the powder is also known to be used in the treatment of some independent diseases, as well as their accompanying symptoms.

In this area, crystalline soda and, in particular, baking soda perform a number of specific tasks: relieves fungal diseases:

- thrush, onychomycosis;

- eliminates heartburn;

- reduces swelling and itching from insect bites or when an allergic reaction occurs;

- relieves pain from burns and promotes rapid tissue regeneration;

- restores fluid lost by the body during poisoning, prevents dehydration;

- relieves infections localized in the oral cavity;

- fights urolithiasis;

- prevents the appearance of caries;

- whitens teeth enamel.

And, of course, the most famous use of crystalline soda is still its use in cooking. However, in this area, only baking soda, that is, sodium bicarbonate, can be used, since this particular substance is characterized by a weak alkaline reaction. Due to the reaction of sodium bicarbonate with an acidic environment, carbon dioxide is released, which gives confectionery products or, for example, an omelet a loose, porous structure and a fluffy appearance.

Being in nature

Crystalline sodium bicarbonate is a natural fossil formed from algae deposits. In nature, it can be found in various forms of crystalline hydrates. Hence, sodium bicarbonate is known as nahcolite, a crystalline hydrate with 2 water molecules (Na2CO3 * NaHCO3 * 2H2O) is trona, with 10 water molecules is sodium and with one water molecule is thermonatrite.

According to geologists, the main reserves of soda in Russia are located in Western Siberia and the Trans-Baikal Territory. Also known are the salt lakes of Tanzania (Natron) and California (Searles).

The throne was first mentioned in the state of Wyoming, USA. In the mid-twentieth century (1938), an exploratory expedition discovered a soda field in Green River).

Potash.

Although in the chemical industry potassium is primarily called potassium carbonate (K2CO3), in agriculture this name covers all potassium salts used in fertilizer production, but mainly potassium chloride (KCl) with a small mixture of potassium sulfate (K2SO4).

Common methods for producing potassium are the electrolysis process involving potassium hydroxide and the most common process based on the chemical reaction of a mixture of potassium chloride and magnesium carbonate with carbon dioxide. As a result of this reaction, an insoluble double salt of potassium bicarbonate and magnesium carbonate is formed, which, when heated, decomposes into potassium and magnesium carbonates, water and carbon dioxide.

Potassium carbonate is used in the production of glass, potash, paints and inks. Potassium carbonate is an important component of special glasses, such as optical and laboratory glasses.

Sodium hydroxide NaOH gets its name from its strong corrosive effect on animal and plant tissue.

Caustic soda is made by electrolyzing a solution of sodium chloride (NaCl) to form sodium hydroxide and chlorine or, less commonly, using an older method based on reacting a solution of sodium carbonate with slaked lime. A large amount of soda ash produced worldwide is used to produce caustic soda.

Harmful effects of sodium carbonate on the human body

The reagent, which is in powder form, can cause irritation to the skin, respiratory system, and eyes. It is especially important to prevent sodium carbonate from coming into contact with the mucous membranes of the eyes and mouth.

The soda ash solution has a highly alkaline environment, so it is advisable to use gloves when working with it. They will protect the skin from redness and possible chemical burns.

Eating too much sodium carbonate may cause the following effects:

- a sharp increase in blood pressure;

- discomfort in the stomach;

- swelling of the whole body;

- a decrease in the level of potassium in the body and, as a result, fatigue, muscle cramps and heart rhythm disturbances.

Application

Due to its antiseptic effect, NaHCO3 is used for medicinal purposes in the treatment of diseases of the gastrointestinal tract (heartburn, belching), burns (relieves pain).

Soda ash, or soda ash, is used in everyday life as a stain remover and also in gardening for pest control.

Sodium hydroxide is used in the chemical and petrochemical industries as a reagent (biodiesel production) and also as a neutralizer for acidic impurities in wastewater systems. In the pulp and paper industry, sodium hydroxide is the main component in the cooking of sulfates. The use of alkali in soap making is relevant: the property of NaOH to wash away fats and oils is used in the production of detergents.

Caustic soda is used only in everyday life

Medical uses of baking soda

Carbonic acid forms two groups of salts: carbonates (mediums) and bicarbonates (acids). The commonplace name for carbonates - soda - appeared in ancient times. Medium and acidic salts should be distinguished by names, formulas and properties. Na2CO3 - sodium carbonate, disodium carbon dioxide, sodium carbonate. It serves as a raw material for glass, paper, soap, and is used as a detergent. NaHCO3 - sodium bicarbonate. The composition suggests that the substance is a monosodium salt of carbonic acid. This compound is distinguished by the presence of two different positive ions: Na and H. Externally, the white crystalline substances are similar, they are difficult to distinguish from each other.

The substance NaHCO3 is not considered sodium bicarbonate because it is taken orally to quench thirst. However, this substance can be used to make a fizzy drink. A solution of this bicarbonate is taken orally in case of increased acidity of gastric juice. In this case, the excess H protons are neutralized, which irritate the walls of the stomach, causing pain and burning.

Baking soda is called high purity baking soda. It undergoes more complete purification from impurities, resulting in more than 99% pure substance remaining. It is used both in official medicine and in traditional treatment.

Baking soda comes in several types:

- Powder for the preparation of solutions used in infusion therapy. Available in packages of 50 g.

- 4% ready-made solution for infusion therapy. Available in containers of 2 ml, 5 ml, 100 ml, 250 ml. Also available in 100 ml, 200 ml and 400 ml bottles.

- Powders for the preparation of solutions for topical use (for washing the skin, mucous membranes, upper respiratory tract, etc.) or for oral administration. Available in paper bags of 10 g, 25 g and 50 g.

- Tablets in dosages of 0.3 and 0.5 grams.

- Suppositories for rectal administration. Available in strengths of 0.3 g, 0.5 g and 0.7 g. Suppositories are sold in packs of 10 suppositories per pack.

It is also worth mentioning the drug “Fleet phospho-soda”, which acts as a laxative.

In pharmaceuticals, the formula for baking soda powder looks like this: the main substance is NaHCO3, the content of which is at least 99.3%. Additional components: Na2CO3 with a content of no more than 0.3% and other impurities, the amount of which does not exceed one hundredth of the main volume.

With the simultaneous use of medicinal soda and tetracycline antibiotics, the effectiveness of the latter is reduced, so doctors do not recommend the simultaneous use of soda therapy and the use of tetracycline antibiotics.

The quantity of each substance is carefully monitored and controlled at the production stage, and the finished product is subject to control testing before release.

The shelf life of the drug is 2 years; it should be stored at a temperature of 15-30 ° C in a place protected from light.

The main difference between baking soda and baking soda is the composition of the substance. Powdered baking soda is produced in compliance with all pharmacological requirements and contains 99.3% sodium bicarbonate, 0.5% sodium carbonate and a minimum amount of sulfates and chlorides.

Pharmacy soda has found application in the treatment of a wide range of diseases:

- Various types of acidosis, including postoperative acidosis or acidosis caused by diabetic coma.

- Increased acidity, stomach and duodenal ulcers.

- Inflammatory processes occurring in the oral cavity (stomatitis, gingivitis, etc.) and in the upper respiratory tract. It is also used as a means to thin thick secretions in the bronchi.

- Inflammatory eye diseases.

Also used for:

- Relief from discomfort during inflammatory processes of the urinary tract. In this case, it is prescribed in the absence of complications.

- Removing earwax.

- Relief from symptoms of air sickness and motion sickness.

Droppers are used strictly under the supervision of a doctor who checks the pH of the blood. The infusion is carried out with a pure solution or in combination with a 5% glucose solution prepared in a 1: 1 ratio. For adults, the solution is administered intravenously using a dropper or rectally, for children - only intravenously. The daily infusion dose for adults should not exceed 200 ml.

Soda tablets are recommended for the appearance of inflammatory processes in the bronchi, accompanied by difficult sputum discharge. For oral administration for heartburn, it is recommended to use soda tablets only as a last resort and after mandatory consultation with a doctor - in its pure form, soda has a strong irritating effect on the stomach, which leads to an increase in the production of hydrochloric acid.

The medicinal solution is widely used for inhalation, treatment of the skin in case of acid contact, rinsing in the treatment of inflammation in the mouth and pharynx, and rinsing. For rinsing, use a 0.5-2% solution, which is prepared from powder. For leather treatment - 2.

Use in everyday life

Crystalline soda is considered a universal remedy, since it can be used both in the industrial sector and in everyday life. Due to their chemical properties, sodium salts of carbonic acid, due to which hydrolysis occurs and the formation of an alkaline reaction of water, are used in various industries.

The designated substance can be used:

- When washing to bleach white fabrics, and to give cleanliness to all types of fabric materials.

- For degreasing tools and cleaning equipment from oily contaminants.

- Can be used to remove various stains on tiles, plumbing, and carpets.

- As a means of clearing clogged sewer pipes.

- Sodium carbonate copes well with various types of scale, including limescale.

Crystal soda is considered one of the best means for eliminating unpleasant odors in the refrigerator, on flooring and more. Also, a solution of crystalline soda can be used as a disinfectant in the fight against bacteria and pathogenic microorganisms.

Soda ash. Production methods. Main types and applications

Sodium ash - sodium carbonate, anhydrous sodium carbonate, chemical formula - Na2CO3

In nature, soda is found in the form of minerals: trona Na2CO3 × NaHCO3 × 2H2O, soda (synonyms sodium and natron) Na2CO3 × 10 H2O and thermosatrite Na2CO3 H2O. Soda crystallizes in a monoclinic system, forms white granular or powdery masses and quickly loses water to the air. Density - 1420 (soda) kg/m3.

The production of sodium carbonate is carried out by the ammonia method by reacting a saturated aqueous solution of sodium chloride and carbon dioxide in the presence of ammonia to form sodium bicarbonate and its subsequent calcination.

NH3 + CO2 + H2O + NaCl → NaHCO3 + NH4Cl + Q

The company produces heavy (grade A) and light (grade B) soda).

The main raw materials for the production of technical soda ash:

Ø high-quality limestones from the Crimean Peninsula;

Ø ecological Sivash brine;

Ø coal - Donbass anthracite;

Ø ammonia water, sulfur compounds from coke plants in Ukraine

Due to the characteristics of the raw material - brine, brines are purified from hardness salts in two stages, which gives the brine a high degree of purity and a low content of insoluble impurities in soda ash.

When high-quality limestone is foamed in shaft kilns, it decomposes into carbon dioxide and calcium oxide.

When purified brine is saturated with carbon dioxide using ammonia as a catalyst, sodium bicarbonate is formed, which is converted to sodium carbonate in steam decarbonizers at high temperatures.

Heavy soda (grade A) is produced on the farm using the monohydrate method from light soda. Heavy soda has the same chemical formula as light soda, but has a high bulk density and is produced in granules. This improves its consumer properties, due to which it is in primary demand in the foreign market.

Carbon dioxide is obtained by calcining limestone in furnaces at a temperature of 1100-1200 ° C according to the reaction:

CaCO3 = CaO + CO2 - Q.

When calcining sodium bicarbonate at a temperature of 150-160 ° C, sodium carbonate is obtained according to the equation:

2NaHCO3 = Na2CO3 + H20 + CO2-Q

The ammonia necessary for the technological process is obtained from ammonium chloride obtained by the action of slaked lime:

2NH4C1 + Ca (OH) 2 = 2NH3 + CaC12 + H20 + Q

The waste product in this process is calcium chloride, which has limited use. Sodium carbonate produced by the ammonia method, called "technical soda ash", is used as a raw material in the production of sodium bicarbonate and caustic soda, it is widely used in the soap, oil, textile, paint and varnish industries and in the production of paints, in the production of various sodium salts, chemicals fibers, artificial leather, dyes, alumina, in water and brine purification and other sectors, as well as in everyday life as a detergent. According to GOST, sodium carbonate obtained by the ammonia method must contain at least 99% Na2CO3.

Mineral nepheline p

(Na, K) 2O-A12Oz • SiO2, serves as a raw material for the production of alumina. However, with complex processing, cement, soda and potash are obtained from nepheline.

The constant need for alumina leads to an increase in the production of soda ash from nepheline raw materials. From the sintered mass, consisting of a mixture of nepheline and limestone, the sodium silicate precipitate used in the production of cement is separated by leaching with water, and the resulting solutions of sodium and potassium aluminates are converted during the carbonization phase into aluminum hydroxide and a solution of soda and potash:

2 (Na, K) A1O2 + CO2 + 3H2O = 2A1 (OH) 3 + (Na, K) 2CO3.

From solutions obtained by evaporation and drying of soda, potash and their mixtures are produced. When processing nepheline ore, about 1.6 tons of soda and potash and up to 10 tons of high-quality cement per 1 ton of alumina are obtained. Although more than 75% of soda ash is currently produced by the ammonia method, the production of soda from nepheline is more promising, since it allows for waste-free use of raw materials and reduces labor costs per unit of production compared to the ammonia method. However, in terms of impurity content, this soda is of lower quality and contains up to 13% potassium sulfate and carbonate.

The resulting “technical soda ash from nepheline raw materials” has a bulk density of about 1.0 t/m3 and is used in the glass and pulp and paper industries, ferrous and non-ferrous metallurgy and other branches of the chemical industry where impurities are harmless.

Applications of sodium carbonate

The described substance is widely used in various sectors of the national economy and everyday life. Sodium carbonate has achieved its greatest popularity in industry, and in particular in glass production, metallurgy, oil production and refining.

Glass production

Sodium carbonate acts as a flux, reducing the melting point of silicon (IV) oxide from 2500 to 500°C. Untreated glass dissolves in water, so in order to avoid this, soda is added to the mixture, which helps reduce the ability of the material to dissolve. So, sodium carbonate is present in almost all window glass and bottles that you see. In addition, the compound is used to produce the following types of glass:

- optical;

- electrovacuum;

- for medical purposes;

- crystal;

- glass blocks and ceramic tiles;

- frit.

Technical soda ash

Metallurgy

Calcium carbonate is necessary in the production of metals: zinc, strontium, tungsten, chromium, lead.

In ferrous metallurgy, soda ash is responsible for the processes of desulfurization and dephosphation of cast iron.

It is also involved in systems responsible for the purification of industrial gases and the neutralization of acidic wastewater.

Chemical industry

The described compound is the starting product in the synthesis of such reagents as sodium hydroxide (NaOH), sodium tetraborate (Na2B4O7), sodium hydrogen phosphate (Na2HPO4). In addition, soda ash is used in the production of synthetic detergents, fatty acids, soap making, and aniline-based dyes.

Oil production and refining

Sodium carbonate, in combination with surfactants, reduces the tension between the water and oil, which allows for better results in oil field development.

Other Applications

The reagent is also in demand in the following areas:

- textile and paper-pulp industry - sodium carbonate is often used in the production of textiles and paper;

- reducing water hardness - sodium carbonate is added to water, the mixture is allowed to brew, and then used for household needs. You cannot drink such liquid;

- impregnation for cigarette filters;

- one of the components for the developing solution in the photo business;

- a food additive that is designed to regulate acidity, increase the shelf life of meat products, act as an emulsifier and leavening agent, and also prevent clumping of bulk products;

- removing peels from vegetables and fruits - a solution based on sodium carbonate is poured into special devices that peel potatoes, carrots, apples and pears;

- cosmetology;

- pharmacy – stabilizer E500 has pronounced antacid and antibacterial properties, due to which it is widely used in the production of antibiotics and anti-tuberculosis drugs. Thus, soda is added to solutions for drip infusions, tablets, solutions for washing damaged areas of the skin and oral cavity, toothpastes and cleansing lotions for skin prone to rashes.

Using soda in everyday life

Sodium carbonate has achieved no less popularity in everyday life. As mentioned above, it was previously used to remove stubborn stains and wash dishes.

In addition to the properties already mentioned, soda ash helps to cope with scale, carbon deposits, and grease stains on the surface of dishes, stoves, and sinks.

It is designed to combat blockages, removes almost any contamination from plumbing equipment (rust, calcified deposits, mold, etc.). So, in order to remove the blockage, pour half a glass of soda into the drain, and then pour 2-3 liters of boiling water over it and leave for half an hour. After 30 minutes, the mixture is washed off with plenty of water.

To get rid of stubborn dirt, sprinkle a damp sponge generously with soda and water, then wipe the contaminated area. Grease, dirt and other contaminants disappear in a matter of minutes.

The reagent in combination with ammonia or hydrogen peroxide solution acts as an effective stain remover and bleach. Laundry soda is used for washing cotton products.

During renovation work, soda ash is used to remove old paint. To do this, sodium carbonate is poured onto the painted surface, covered with a thick damp cloth and left for 10-12 hours. After this time, the paint comes off easily from any surface.

Soda Ash

Sodium carbonate is also used to gently bleach fabrics and remove stains from favorite things. To do this, soda ash is mixed with warm water and applied to the stain, after 15 minutes the solution is washed off. If the stain does not disappear, repeat the procedure. To speed up the effect, you can add ammonia to the mixture.

When baking culinary products, only sodium bicarbonate (another name for baking soda) is used. Soda ash is not used for these purposes - it is not suitable for human consumption and poses a danger to human health.

But baking soda can be found in powdered milk, as well as products made with chocolate or cocoa powder. In addition, the compound is used to process vegetables using alkaline peeling technology.

When working with non-food varieties of sodium carbonate, it is important to take precautions: protect the sensitive skin of your hands, keep the product used as far as possible from the mucous membranes of the mouth and eyes.