Sodium hydroxide is of great importance for industry, which is why it is widely used. Caustic, or caustic soda, is used in almost all areas of human life - from chemical production to the food industry. Despite its corrosive properties, this alkali is registered as a food additive E524. This does not mean that it is not harmful to health at all, although caustic soda is not dangerous in minimal doses.

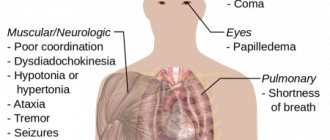

Sodium hydroxide is extremely dangerous in excess dosages

TECHNICAL CAUSE SODIUM GRADE RM (membrane solution)

Container, shipment and packaging in steel railway and road tanks. At the consumer's request, the technical caustic soda solution is poured into special containers with a capacity of 1000 dm3, consisting of a metal lathing, a wooden pallet and a plastic container (Eurocube).

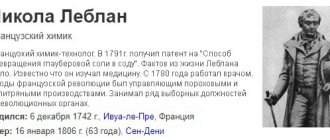

Caustic soda (sodium hydroxide). Chemical formula Na-OH Molecular mass (according to international atomic masses 2011) - 39.997. The density of the substance is 1.5 g/cm3 . Other names are caustic soda, caustic, caustic alkali. The history of the trivial names of both sodium hydroxide and other alkalis is interesting - the name “caustic alkali” is determined by the property of corroding skin, paper, glass and causing severe burns. Until the 17th century, alkali (French alkali) was also called sodium and potassium carbonates. In 1736, the French scientist A. L. Duhamel du Monceau first distinguished these substances: - sodium hydroxide was called caustic soda, and sodium carbonate was called soda ash (after the Salsola Soda plant, from the ash of which it was extracted), potassium carbonate in turn we named it - we'll potash it. Today, sodium salts of carbonic acid are commonly called soda. In English and French, the word sodium means sodium and potassium means potassium.

History of the discovery of the substance

The first mention of a compound whose properties are reminiscent of caustic soda appears in ancient times. Even the Bible contains some information about the substance neter, extracted from the Egyptian lakes. Presumably this was caustic soda.

Aristotle, Plato and other ancient Greek and Roman philosophers and scientists also mentioned the substance nitrum, which was extracted from natural reservoirs and sold in the form of large differently colored pieces (black, gray, white). After all, nothing was known about purification methods at that time, so it was not possible to separate the compound from the coal that polluted it.

Soap making was introduced in 385 BC. The process was based on caustic soda. Its formula, of course, was not yet known, but this did not stop it from being extracted from the ash of plants of the Solyanka genus, from lakes and used for cleaning household items, washing clothes, and making various soaps.

A little later, the Arabs learned to add essential oils and aromatic substances to the product. Then the soap became beautiful and smelling good. The active development of soap-making processes and technologies began.

Until the 17th century, caustic soda, the properties of which were widely used, remained unstudied as a chemical compound. It was combined with substances such as soda, potassium hydroxide, potassium and sodium carbonates. All of them were called caustic alkalis.

Later, the scientist Duhamel du Monceau was able to prove the difference between these substances and divided them into alkalis and salts. Since then, caustic soda received its true and constant name to this day.

Industrial methods for producing sodium hydroxide

On an industrial scale, sodium hydroxide is produced by electrolysis of solutions of halite (rock salt NaCl) with the simultaneous production of hydrogen and chlorine:

2NaCl + 2H2O = H2↑ + Cl2↑ + 2NaOH

Today, caustic alkali and chlorine are produced by three electrochemical methods. Two of which are electrolysis with a solid asbestos or polymer cathode (diaphragm grade RD and membrane grade RM production methods), the third is electrolysis with a liquid mercury cathode (mercury production method - grade RR).

Technical caustic soda, depending on the production technology, is produced in the following PP grades - mercury solution, obtained directly at the stage of mercury electrolysis; TR - solid mercury (flaked), obtained from a mercury solution of caustic soda grade PP by evaporation, drying and flaking; RD is a diaphragm solution obtained from a primary diaphragm solution of caustic soda (12% - 15%) by evaporation to 44% - 50%; TD - solid diaphragm (fused), obtained from a diaphragm solution of RD grade caustic soda by evaporation; RM-B is a membrane solution obtained directly at the stage of membrane electrolysis; RM-B is a membrane solution obtained from a solution of caustic soda grade RM-B by evaporation to 46% - 48%; MA is a membrane solution obtained by evaporation to 48% - 52% of the primary sodium hydroxide solution at the stage of membrane electrolysis with special preparation of the initial sodium chloride solution. Of all the electrochemical production methods, the easiest and most convenient method is electrolysis with a mercury cathode. However, this method causes significant harm to the environment due to evaporation and leakage of metallic mercury. The membrane production method is the most effective, least energy-intensive and most environmentally friendly. But this method is not so simple, since it requires raw materials of higher purity. Caustic alkalis that are produced using electrolysis with a liquid mercury cathode are much cleaner than those produced by the diaphragm method. This is important for some industries. Thus, in the production of artificial fibers, only caustic obtained by electrolysis with a liquid mercury cathode can be used. World practice accepts all three methods for producing chlorine and caustic soda, with a clear tendency towards increasing the share of membrane electrolysis. In the Russian Federation, approximately 35% of all caustic soda produced is produced by electrolysis with a mercury cathode and 65% by electrolysis with a solid cathode (diaphragm and membrane methods). Application and production of caustic soda More than 57 million tons of caustic alkali are produced and consumed annually in the world. Caustic soda is used in various industries and for domestic needs: in the pulp and paper industry in the production of paper, cardboard, artificial fibers, and fiberboards. in civil defense for degassing and neutralization of toxic substances, in rebreathers (self-contained breathing apparatus (IBA), for cleaning exhaled air from carbon dioxide. in chemical industries - for neutralizing acids and acid oxides, as a reagent or catalyst in chemical reactions, in chemical analysis for titration, for aluminum pickling and in the production of pure metals, in oil refining - for the production of oils, for the production of biodiesel - obtained from vegetable oils and used to replace conventional diesel fuel, for saponification of fats in the production of soap, shampoo and other detergents. as an agent for dissolving blockages of sewer pipes. in food preparation: in the production of chocolate and cocoa, drinks, ice cream, caramel coloring, for softening olives and in the production of bakery products. Registered as a food additive E524. Technical sodium hydroxide GOST R 55064-2012 Technical caustic soda (sodium hydroxide) is developed for the chemical, petrochemical, pulp and paper industries, non-ferrous metallurgy and other sectors of the national economy. The physical state of sodium hydroxide (GOST 55064-2012) implies a liquid and solid state (flaky). Liquid technical sodium caustic is produced in the following grades: RR - mercury solution; < RD - diaphragm solution; RM(A, B, C) is a membrane solution. Technical purified caustic soda GOST 11078-78 Purified caustic soda grade RR, which is obtained by electrolysis of a sodium chloride solution using a mercury cathode, is used in the production of: pure metals, chemical threads and fibers, pulp and paper, and other industries . Differences in caustic soda by grade Purified caustic soda is produced in two grades, depending on the area of application: grade A - for the production of chemical fibers, ion-exchange resins, reagents, and the medical industry; grade B - for the production of non-edible cellulose film, pure metals, in the pulp and paper industry, for the production of mineral fertilizers. We sell Caustic soda (caustic soda RD 46%) Caustic soda, brand RD - diaphragm solution 46% premium grade GOST 2263-79. Caustic soda of the RD brand is an aqueous solution of sodium hydroxide (a product of the chemical process of diaphragm electrolysis of a solution of table salt). Caustic soda grade RD is used in the production of viscose silk and in the bleaching of fabrics. It has also found application in soap making, in the aniline dye industry, in the production of aluminum and sodium metal. Alkaline batteries and soluble glasses are also produced using RD grade caustic soda in production. In the chemical industry, caustic soda is used in the production of synthetic phenol, dyes, glycerin, and plastics. RD is also relevant for the purification of petroleum and mineral oils. Store liquid caustic soda in specialized containers that are resistant to corrosion by alkali. Sold in bulk with delivery throughout Russia.

Sodium hydroxide is a chemical reagent with the formula NaOH. It also has other names: caustic, caustic alkali, caustic soda. The reagent is a powder of tiny flakes or pieces of round or semicircular shape of pure white color. Quickly dissolves in aqueous and alcoholic media. There can be two types: analytical grade - pure for analysis and chemically pure - pure purified. You can buy caustic soda technical granulated GR highest grade STO 00203275-206-2007 wholesale and retail from Khimexpert LLC at the best prices. Buy technical caustic soda granulated GR premium grade STO 00203275-206-2007 in Nizhny Novgorod at the best price. You can view product descriptions, terms of payment and delivery, and leave a request. I will sell technical caustic soda granulated (caustic soda, sodium hydroxide NaOH). Granulated caustic soda (caustic). STO 00203275-206-2007. Technical sodium hydroxide granules are packaged in two-layer valve polyethylene bags, in valve bags, moisture-resistant, closed, with a fabric laminate, for bulk chemical products. Technical granulated sodium caustic is transported by rail, road and water transport in packaged form. By rail, cargo is transported by railcar shipments in covered wagons. Loading and unloading of sodium caustic is carried out directly from the supplier or consumer. For questions regarding the purchase of technical granulated caustic soda and obtaining detailed advice on product properties, delivery conditions and conclusion of an agreement, please contact our managers. Buy caustic soda at a competitive price on the offer of the leading supplier ChemExpert. Inexpensive prices for caustic soda only in Nizhny Novgorod. Technical caustic soda (flakes), I will sell technical caustic soda granulated/flaked (caustic soda, sodium hydroxide NaOH) in Nizhny Novgorod, wholesale and retail price, where to buy in the KhimExpert company you can buy caustic soda at the price of rubles per ton, as well as order delivery of a chemical substance to various regions of Russia and the CIS. We sell certified raw materials produced by the most famous and proven Caprolactam Plant in Dzerzhinsk, Khimprom OJSC, Novocheboksarsk, KCCHK OJSC, Kirovo-Chepetsk; OJSC "Novomoskovsky Chlorine" Novomoskovsk, OJSC "Kaustik" Sterlitamak.

Receiving in different ways

For laboratory and industrial purposes, caustic is obtained in different ways, but there are the most popular methods that are easy to use and allow you to obtain a high-quality product.

Diaphragm method

It is considered the simplest in terms of organization and materials used for the design of the electrolyzer. According to this method, the brine solution is supplied to the anode through the cathode grid by an asbestos diaphragm. In this case, hydrogen is removed using a special tube, without penetrating through the mesh due to the countercurrent, due to which the production of alkali is separated from chlorine. The release of oxygen harms the process and can lead to destruction of the anode.

The diaphragm process is one of the most common methods for the synthesis of sodium hydroxide

The alkali solution obtained as a result of the reaction is evaporated, the impurities that precipitate are removed, and brought to crystallization. The chlorine released during the reaction is liquefied or used in the production of chlorine-containing products. The diaphragm method is valued for its simplicity and low cost, so it is still widely used for producing caustic soda.

Membrane production

This method is considered the most effective, but it is quite difficult to organize. The processes are similar to the diaphragm method, but instead of a permeable diaphragm, the anode is separated from the cathode by a dense membrane through which anions cannot pass, while cations leak freely. In this case, production is cleaner, with a minimum amount of by-products and impurities. Another feature is the presence of two pots, and not one, as in diaphragm synthesis.

Despite the complexity of membrane production, it can produce a purer alkali

The saline solution penetrates the anode in the same way, and deionized water is supplied to the cathode. As a result, alkali and hydrogen flow out of the cathode space almost without impurities, and in addition, they practically do not require evaporation, since they are in an acceptable concentration.

Membrane systems are quite complex and require careful preliminary purification of the supplied solutions due to the vulnerability of cation-exchange membranes to impurities and the high cost of the material from which they are made. In addition, it is necessary to install management and control systems for the process, which in itself is difficult and expensive.

The membrane production process is extremely expensive and complex, so it is rarely used

Using liquid mercury cathode

Electrolysis using mercury produces a much purer product than the diaphragm method. In addition, when compared with the membrane method for producing caustic soda, the mercury method is much simpler.

The installation consists of the following components:

- electrolyser;

- amalgam decomposer;

- mercury pump;

- supply tubes.

The cathode is a continuous flow of mercury supplied by a pump; anodes are most often made of graphite or carbon. In parallel with the mercury flow, a solution of table salt passes through the electrolyzer.

Mercury is extremely expensive and is very harmful to the environment, so the mercury method is almost never used for the production of alkali

At the anode, the process of oxygenation of chlorine ions from the saline solution occurs by releasing chlorine. Chlorine is removed from the spent anolyte, the chlorine is extracted, and the anolyte is saturated and freed from impurities, after which it is fed back into the electrolyzer.

A weak solution of sodium in mercury is formed at the cathode - sodium amalgam. Next, the amalgam enters the decomposer along with highly purified water. There, the sodium amalgam is almost completely decomposed by water as a result of a spontaneous chemical process. As a result, a caustic solution, hydrogen and mercury are formed.

As a result of the mercury method, the sodium solution contains almost no impurities and is considered high quality. The mercury purified from sodium is sent back to electrolysis, the hydrogen is subject to purification.

However, due to the high cost of mercury and the unenvironmental friendliness of the method, the use of a mercury cathode is gradually being replaced by other methods for producing sodium alkali, in particular, the membrane method.

Features and properties of caustic soda in assortment

In the company's catalog you can buy liquid technical caustic soda of the following concentration: caustic soda solution 46% or technical caustic soda solution 50%. offers to buy caustic soda (caustic soda) in bulk at competitive prices. From us you can buy granulated caustic soda (caustic soda) wholesale from the manufacturer with delivery throughout Russia. I sell caustic soda, granulated caustic soda (caustic soda) of the GR brand, flaked caustic soda of the TR brand (Caustic soda), reagent grade caustic soda (Soda caustic), liquid sodium hydroxide brand RD (caustic soda ash). Flaked sodium hydroxide (other names: caustic soda, caustic soda, caustic soda, caustic alkali) is the most common alkali, chemical formula NaOH. It is a scaly white mass, highly hygroscopic, “disperses” in air, actively absorbing water vapor from the air. It dissolves well in water and releases a large amount of heat. The caustic soda solution is soapy to the touch. Sodium hydroxide is obtained from a solution of purified sodium hydroxide. Sodium hydroxide “technical” flake is a chemically pure reagent (pure for analysis, with a substance content of at least 98%) in the form of thin white flakes. The substance actively absorbs moisture from the environment and gradually spreads. At the same time, it absorbs carbon dioxide, turning into sodium carbonate. Dissolution in water is accompanied by the release of a large amount of heat. Aggressive towards organic materials, destroys proteins and fats. The solution is very caustic and dangerous, causing severe chemical burns. Reagent of the 2nd class of danger to humans. When working with it, you must use splash goggles, rubber gloves, and special clothing. There are several industrial methods for producing sodium hydroxide, but the most cost-effective is electrochemical - electrolysis of a solution of the natural mineral halite (fossil salt NaCl). Caustic soda is used in soap making, the pulp and paper industry, chemical industry, textile industry, metallurgy, oil refining, food industry, cosmetology and in many other areas. Demanded in everyday life for clearing blockages in pipes. In civil defense - a means to neutralize acids and some toxic substances. Used in self-contained breathing apparatus to remove CO2 from exhaled air. Caustic soda is a strong alkali that reacts with almost all chemicals, regardless of conditions. Moreover, each reaction is accompanied by an intense release of heat. The melting point of this hygroscopic chemical product is +299C. By reacting with acids and oxides, caustic soda forms salts, with which its active reaction is also possible. Sodium hydroxide is soluble in glycerin and alcohols. It interacts with non-metals and metals. The release of large amounts of hydrogen and heat occurs during exothermic reactions with aluminum, zinc and tin. Caustic soda is produced by the electrolysis method, then purified from impurities, granulated or reduced to a powder state. Technical caustic soda is produced in accordance with GOST 2263-79.

Chemical properties of sodium hydroxide. Chemical reactions of sodium hydroxide:

Sodium hydroxide is a chemically active substance, a strong chemical base.

Aqueous solutions of NaOH have a strong alkaline reaction (pH of a 1% solution = 13.4).

The chemical properties of sodium hydroxide are similar to those of other alkali metal hydroxides. Therefore, it is characterized by the following chemical reactions:

1. reaction of sodium hydroxide with sulfur:

3S + 6NaOH → 2Na2S + Na2SO3 + 3H2O (t = 50-60 °C).

The reaction produces sodium sulfide, sodium sulfite and water. In this case, sodium hydroxide is used as a starting material in the form of a diluted solution.

2. reaction of sodium hydroxide with chlorine:

2NaOH + Cl2 → NaCl + NaClO + H2O.

The reaction produces sodium chloride, sodium hypochlorite and water. In this case, sodium hydroxide is used as a starting material in the form of a cold diluted solution.

The reactions of sodium hydroxide with other halogens proceed similarly.

3. reaction of sodium hydroxide with aluminum:

2Al + 6NaOH → 2NaAlO2 + 3H2 + 2Na2O (t = 450 °C).

The reaction produces sodium aluminate, hydrogen and sodium oxide.

4. reaction of sodium hydroxide with aluminum and water:

2Al + 2NaOH + 6H2O → 2Na[Al(OH)4] + 3H2.

As a result of the reaction, sodium tetrahydroxoaluminate and hydrogen are formed. In this case, sodium hydroxide is used as a starting material in the form of a concentrated solution.

This reaction was used in the first half of the 20th century in aeronautics: to fill balloons and airships with hydrogen in the field, since this reaction does not require sources of electricity, and the starting reagents for it can be easily transported.

5. reaction of sodium hydroxide with zinc:

Zn + 2NaOH → Na2ZnO2 + H2 (t = 550 °C).

As a result of the reaction, sodium zincate and hydrogen are formed.

6. reaction of sodium hydroxide with zinc and water:

Zn + 2NaOH + 2H2O → Na2[Zn(OH)4] + H2.

As a result of the reaction, sodium tetrahydroxozincate and hydrogen are formed. In this case, sodium hydroxide is used as a starting material in the form of a concentrated solution.

7. reaction of sodium hydroxide with phosphoric acid:

H3PO4 + NaOH → NaH2PO4 + H2O.

As a result of the reaction, sodium dihydrogen orthophosphate and water are formed. In this case, the following starting materials are used: phosphoric acid in the form of a concentrated solution, sodium hydroxide in the form of a diluted solution.

8. reaction of sodium hydroxide with nitric acid:

NaOH + HNO3 → NaNO3 + H2O.

As a result of the reaction, sodium nitrate and water are formed. In this case, nitric acid is used as a starting material in the form of a diluted solution.

9. reaction of sodium hydroxide with nitric acid:

NaOH + HNO3 → NaNO3 + H2O.

As a result of the reaction, sodium nitrate and water are formed. In this case, nitric acid is used as a starting material in the form of a diluted solution.

The reactions of sodium hydroxide with other acids proceed similarly.

10. reaction of sodium hydroxide with hydrogen sulfide:

H2S + 2NaOH → Na2S + 2H2O,

H2S + NaOH → NaHS + H2O.

As a result of the reaction, in the first case, sodium sulfide and water are formed, in the second, sodium hydrosulfide and water. In this case, sodium hydroxide in the first case is used as a starting substance in the form of a concentrated solution, in the second case - in the form of a diluted solution.

11. reaction of sodium hydroxide with hydrogen fluoride:

HF + NaOH → NaF + H2O,

2HF + NaOH → NaHF2 + H2O.

As a result of the reaction, in the first case, sodium fluoride and water are formed, in the second, sodium hydrofluoride and water. In this case, sodium hydroxide and hydrogen fluoride in the first case are used as a starting material in the form of a diluted solution, in the second case, hydrogen fluoride is used in the form of a concentrated solution.

12. reaction of sodium hydroxide with hydrogen bromide:

HBr + NaOH → NaBr + H2O.

As a result of the reaction, sodium bromide and water are formed. In this case, sodium hydroxide and hydrogen bromide are used as a starting material in the form of a diluted solution.

13. reaction of sodium hydroxide with hydrogen iodide:

HI + NaOH → NaI + H2O.

As a result of the reaction, sodium iodide and water are formed. In this case, sodium hydroxide is used as a starting material in the form of a diluted solution.

14. reaction of sodium hydroxide with zinc oxide:

ZnO + 2NaOH → Na2ZnO2 + H2O (t = 500-600 °C).

Zinc oxide is an amphoteric oxide. As a result of the reaction, sodium zincate and water are formed.

15. reaction of sodium hydroxide with zinc oxide and water:

ZnO + NaOH + H2O → Na[Zn(OH)3] (t = 100 °C),

ZnO + 2NaOH + H2O → Na2[Zn(OH)4] (t = 90 °C).

Zinc oxide is an amphoteric oxide. As a result of the reaction, in the first case, sodium trihydroxozincate and water are formed, in the second case, sodium tetrahydroxozincate. In this case, sodium hydroxide is used as a starting substance in the first case in the form of a 40% diluted solution, in the second - in the form of a 60% diluted solution.

16. reaction of sodium hydroxide with aluminum oxide:

Al2O3 + 2NaOH → 2NaAlO2 + H2O (t = 900-1100 °C).

Aluminum oxide is an amphoteric oxide. As a result of the reaction, sodium aluminate and water are formed.

17. reaction of sodium hydroxide with aluminum oxide and water:

Al2O3 + 6NaOH + 3H2O → 2Na3[Al(OH)6],

Al2O3 + 2NaOH + 3H2O → 2Na[Al(OH)4].

Aluminum oxide is an amphoteric oxide. As a result of the reaction, in the first case, sodium hexahydroxoaluminate is formed, in the second case, sodium tetrahydroxoaluminate. In this case, sodium hydroxide is used as a starting material in the second case in the form of a concentrated hot solution.

18. reaction of sodium hydroxide with iron oxide:

Fe2O3 + 2NaOH → 2NaFeO2 + H2O (t = 600 °C, p).

Iron oxide is an amphoteric oxide. As a result of the reaction, sodium ferrite and water are formed. The reaction occurs when the starting substances fuse.

The reactions of sodium hydroxide with other amphoteric oxides proceed similarly.

19. reaction of sodium hydroxide with carbon monoxide (carbon dioxide):

NaOH + CO2 → NaHCO3.

As a result of the reaction, sodium bicarbonate is formed.

20. reaction of sodium hydroxide with sulfur oxide:

SO2 + NaOH → NaHSO3.

As a result of the reaction, sodium hydrosulfite is formed. In this case, sodium hydroxide is used as a starting material in the form of a diluted solution.

21. reaction of sodium hydroxide with silicon oxide:

2NaOH + SiO2 → Na2SiO3 + H2O (t = 900-1000 °C),

4NaOH + SiO2 → Na4SiO4 + 2H2O.

As a result of the reaction, in the first case, sodium silicate and water are formed, in the second case, sodium orthosilicate and water. In this case, sodium hydroxide is used as a starting substance in the second case in the form of a concentrated solution.

22. reaction of sodium hydroxide with aluminum hydroxide:

Al(OH)3 + NaOH → NaAlO2 + 2H2O (t = 1000 °C),

Al(OH)3 + NaOH → Na[Al(OH)4].

Aluminum hydroxide is an amphoteric base. As a result of the reaction, in the first case, sodium aluminate and water are formed, in the second case, sodium tetrahydroxyaluminate. In this case, sodium hydroxide is used as a starting substance in the second case in the form of a concentrated solution.

23. reaction of sodium hydroxide with zinc hydroxide:

Zn(OH)2 + 2NaOH → Na2[Zn(OH)4].

Zinc hydroxide is an amphoteric base. As a result of the reaction, sodium tetrahydroxozincate is formed. In this case, sodium hydroxide is used as a starting material in the form of a concentrated solution.

24. reaction of sodium hydroxide with iron hydroxide:

Fe(OH)3 + 3NaOH ⇄ Na3[Fe(OH)6].

Iron hydroxide is an amphoteric base. As a result of the reaction, sodium hexahydroxoferrate is formed.

The reactions of sodium hydroxide with other amphoteric hydroxides proceed similarly.

25. reaction of sodium hydroxide with ferrous sulfate:

FeSO4 + 2NaOH → Fe(OH)2 + Na2SO4 (kat = N2).

As a result of the reaction, iron hydroxide and sodium sulfate are formed.

26. reaction of sodium hydroxide with copper chloride:

CuCl2 + 2NaOH → Cu(OH)2 + 2NaCl.

As a result of the reaction, copper hydroxide and sodium chloride are formed. In this case, sodium hydroxide is used as a starting material in the form of a diluted solution.

27. reaction of sodium hydroxide with lead nitrate:

Pb(NO3)2 + 2NaOH → Pb(OH)2 + 2NaNO3.

As a result of the reaction, lead hydroxide and sodium nitrate are formed. In this case, sodium hydroxide is used as a starting material in the form of a diluted solution.

28. reaction of sodium hydroxide with aluminum chloride:

AlCl3 + 3NaOH → Al(OH)3 + 3NaCl.

As a result of the reaction, aluminum hydroxide and sodium chloride are formed. In this case, sodium hydroxide is used as a starting material in the form of a diluted solution.

The reactions of sodium hydroxide with other salts proceed similarly.

Application of caustic soda in industries and industries

Caustic soda is intensively used: at pulp and paper mills, using sodium hydroxide, they produce cardboard, some types of papers, and fiberboards; at petrochemical industry enterprises, the substance is used to purify petroleum fractions and oils; as a food additive, E524 is used to regulate the acidity of some products, as well as for cleaning and disinfecting equipment; in the production of cosmetics it is used as an emulsifier and saponifier in soap, shampoos and creams; in enterprises producing household chemicals, it is used to prepare disinfectants. Caustic soda (caustic soda) Caustic soda is widely used in modern industries. For example, in the pulp and paper industry it is used for delignification of cellulose. This type of soda is used in the manufacture of detergents, shampoos, and soaps for saponification of fats. In the chemical industry, this substance is indispensable and is used in the production of almost any product. Since caustic soda has such wide applications, it is necessary to choose a reliable supplier from whom you can buy quality raw materials. One of the main selection criteria is production experience and the scale of the enterprise. The larger the supplier, the less likely it is to receive low-quality products.

Synonyms of names

It should be noted that the name of this substance is not the same and has several synonyms. In total there are 6 different options:

- sodium hydroxide;

- caustic soda;

- caustic soda;

- sodium lye;

- caustic;

- caustic alkali.

This compound is called caustic soda in common people and industry. In chemical syntheses, it is more correct to say sodium alkali or caustic soda. This does not change the formula. The most common name is caustic. The correct name from the point of view of the systematic nomenclature of substances is sodium hydroxide.

Safety precautions when handling caustic soda

As the name suggests, caustic soda is a dangerous substance. In production it is used in the form of an aqueous solution. If handled incorrectly, it can have serious consequences for human health. Failure to comply with safety precautions can lead to chemical burns of varying severity and cause irreparable harm to appearance and health. If an aqueous solution gets on the skin, it is necessary to immediately remove the substance from the skin with a special means, after which the burn site should be rinsed under running water. Neither liquid nor solid soda can be washed off with water, since contact between them will result in a chemical reaction. To prevent negative consequences, it is necessary to conduct safety training, as well as constant monitoring of its compliance. No enterprise is insured against accidents, so you should not neglect the means that can eliminate the consequences of dangerous contact. The gaseous state of this substance, sodium hydroxide, has a detrimental effect on human health. Of course, a liquid technical solution requires a long evaporation time. Provided proper storage conditions are provided, it is harmless to human health. This is achieved due to the low concentration of the substance in the air. But even if all storage standards are observed, safety rules should not be neglected.

Chemical formula and molecule structure

If we consider this substance from a chemical point of view, it will consist of two ions: sodium cation (Na+) and hydroxide anion (OH-). Bonding with each other due to the electrostatic attraction of differently charged particles, these ions form caustic soda. The empirical formula will be NaOH.

The hydroxo group is formed by a covalent polar bond between oxygen and hydrogen, while it is held by an ionic bond with sodium. In solution, alkali completely dissociates into ions, being a strong electrolyte.

Loading and packing of caustic soda

In what container is caustic soda shipped? Carrying out analyzes related to the determination of mass fractions of total nitrogen, aluminum and other heavy metals. Any manufacturer is required to carry out such analyzes, and no less frequently than on every twentieth batch of goods. This is required by regulatory standards. Widely used in soap making at home and industrial scale. Acts as the main reagent. Moreover, in soap making sodium hydroxide can be used not of high purity, but of ordinary purification. Production of chemical fibers and other reagents. It can also be used in medicine, pulp and paper, gas, petrochemical and metallurgical industries. Hazard class Caustic soda is a fairly caustic substance belonging to hazard class 2. May cause severe chemical burns. Analyzes with this reagent are carried out strictly according to the instructions. Store the jar with the reagent only in a dry, dark place with the lid tightly closed. As with any alkali, precautions must be taken to avoid contact of the powder with the skin or eyes. It is unacceptable to use a reagent of dubious origin without compliance with GOST, with an expired expiration date, or in case of violation of storage conditions. Conditions for transportation and storage of caustic soda. Transportation of caustic soda is permitted by all types of transport in packaged form in covered vehicles in accordance with the rules for the transportation of dangerous goods in force for this type of transport. Loading rate into wagons: when packed in bags with a weight capacity of 25 kg to 60 tons, these are tank trucks and railway tanks for caustic soda solution, respectively. Packaged caustic soda must be stored in closed warehouses that prevent moisture from entering, in stacks on pallets, flooring, and gratings. Caustic soda packed in polypropylene bags with a valve must not be stored in a vertical position. When stored in heated warehouses, bags and transport packages with caustic soda are placed at a distance of at least one meter from heating devices. Guaranteed shelf life is one year from the date of manufacture.

Special properties of caustic soda

Is a caustic substance. Refers to highly hazardous substances. If it comes in contact with the skin, it causes chemical burns. Fire and explosion-proof.CAUSID SODIUM SOLUTION: Caustic soda solution is transported by all types of transport, except aviation, in accordance with the rules for the transportation of goods in force for this type of transport: in bulk in railway tanks in accordance with the rules for the transportation of dangerous goods approved by the Ministry of Railways; in containers, barrels and small containers - by road; in containers and barrels - by water transport. The degree (level) of tank filling is calculated taking into account the full use of their capacity (carrying capacity) and the volumetric expansion of the product with a possible temperature difference along the route. Containers, barrels and small containers are filled to no more than 98% of their capacity. When the air temperature is below 10 °C, the product must be heated before unloading from the tanks.

Liquid sodium lye

In addition to crystalline, there is also an aqueous solution of caustic soda. Its formula is the same as for solid. Chemically, solutions are more applicable and convenient to use. Therefore, caustic is used more often in this form.

Caustic soda solution, the formula of which is NaOH, is used in all of the above areas. It is only inconvenient during transportation, since it is better to transport dry caustic. In all other properties it is in no way inferior to crystals, and in some even surpasses them.

CAUSE SODIUM PURIFIED SOLUTION GOST 11078-78 application in production

For the production of: chemical fibers; ion exchange resins; reagents; medical industry; non-edible cellulose film; pure metals; in the pulp and paper industry; mineral fertilizers. CAUSED SODIUM, FLAKED, AND ALSO GRADES RD, RM-B, RM-V is used: in the pulp and paper industry, in the production of paper, cardboard, artificial fibers, wood-fiber boards; for saponification of fats in the production of soap, shampoo and other detergents . used in the field of industrial washing to clean stainless steel products from grease and other oily substances, as well as mechanical processing residues; in the chemical industries - for neutralizing acids and acid oxides, as a reagent or catalyst for chemical reactions in oil refining - for the production of oils; for the production of biodiesel fuel; as an agent for dissolving blockages in sewer pipes, in the form of dry granules or in gels (along with potassium hydroxide). Sodium hydroxide disaggregates the blockage and facilitates its easy movement further along the pipe. In civil defense for degassing and neutralizing toxic substances; in the textile industry - for the mercerization of cotton and wool. With short-term treatment with caustic soda followed by washing, the fiber acquires strength and a silky shine; for washing tire molds; in cooking: for washing and peeling fruits and vegetables, in the production of chocolate and cocoa, drinks, ice cream, caramel coloring, for softening olives and giving them a black color in the production of bakery products. Registered as a food additive E-524; in cosmetology for the removal of keratinized skin, warts, papillomas; in photography - as an accelerating substance in developers for high-speed processing of photographic materials.

Caustic soda properties and uses

The chemical formula of caustic soda is NaOH. It has other names: caustic soda, caustic soda, sodium hydroxide, caustic alkali. It looks like small, scaly, white, odorless granules or a colorless liquid. It has the following properties: hygroscopic, granules spread in air, absorbing water; dissolves in water, releasing a large amount of heat; does not react with plastic, rubber, steel, cast iron; contact with zinc, aluminum surfaces gives a violent reaction; effectively dissolves fat and all organic substances: hair, paper, food debris; is volatile, stored in a tightly closed container. Precautions and safety precautions. Caustic soda is a strong poisonous alkali. If its solution gets on the skin, burns and ulcers may occur. It belongs to hazard class 2, so when using it is necessary to take precautions: work in a mask, goggles, rubber gloves, special clothing; ventilate the room well; > store closed in places inaccessible to children and animals; in case of contact with skin, neutralize with vinegar , rinse the affected area with water; if it gets into the eyes, rinse with plenty of water.> Caustic soda is a product of chemical synthesis; such a substance does not exist in nature. It is sold in hardware stores, household chemical departments, packaged in plastic jars or thick plastic bags weighing from 250 g to 30 kg. Caustic soda has a very wide range of applications in various industries: textile, chemical, food, oil, etc. Most washing powders, shampoos, detergents, cleaning products contain caustic. It is used in the production of paper, viscose, olives, ice cream, cocoa, and chocolate. In the food industry it is known as food additive E524. In everyday life, the main purpose of sodium hydroxide is to combat fatty and organic contaminants. It is used for cleaning sewers, degreasing surfaces, making soap by hand, bleaching and washing clothes, controlling garden pests, and sanitizing premises. Cleaning sewers. Sewer pipes tend to become clogged: grease, soap scum, and organic residues settle on their inner surface. All this is compressed, reducing the lumen of the pipe, the water does not drain well, and an unpleasant odor appears from the drain hole. The reasons can be both technical and operational: incorrect slope of the sewer system; roughness, burrs on the inner surface of the pipes; many rough joints; lack of a grate on the drain hole of the sink or bathtub, and as a result, organic contaminants entering the drain - hair, paper, pieces of food; frequent draining of fatty food debris without subsequent rinsing of the pipes with hot water.

Cleaning cesspools using alkali (caustic soda)

All sewage is drained into cesspools in a country house or in a private house. Most of them have a liquid fraction, which leaves through the earthen walls, and a thick fraction accumulates at the bottom and is removed as necessary. Very often the walls of cesspools are covered with a dense organic film, and the water stops draining. As a result, sewage waste quickly fills the pit. Caustic soda is used to dissolve the film and clean the earthen walls. Its quantity is taken at the rate of 4 kg per 1 cubic meter of cesspool. Having previously dissolved the soda in water, carefully pour the caustic alkali solution into the pit. The effect occurs after 2-3 days. The film gradually dissolves, the liquid level decreases, and a silty sediment remains at the bottom.

Alkali as a means for cleaning contaminated surfaces

Caustic soda is used to clean enamel sinks, stove surfaces, and heavily soiled kitchen utensils from grease, soot, and carbon deposits. To do this, you need to mix it with liquid detergent or washing powder, dilute it with water to a paste consistency, and apply it to the surface. After 20–30 minutes, rinse with plenty of water. A proven and effective cleaning method is to boil contaminated dishes in a solution of the following composition:> water - 5 l; caustic - 100 g; laundry soap shavings - 50 g; stationery glue - 75 g. The boiling container should be enameled or steel. The solution should be stirred well, brought to a boil, and all dirty dishes should be placed in it. Keep metal dishes on low heat for 2 hours, glass and porcelain dishes for 10 minutes. Then take it out and rinse well. Caustic soda cannot be used on galvanized, aluminum and Teflon surfaces. They can be ruined.

Caustic soda in crop production

Sodium hydroxide is used in the fight against garden pests and plant diseases, for the disinfection of vegetable stores, barns, animal cages, and greenhouses. To treat plants, make a solution: add 1 spoon of caustic to 2 liters of water, stir thoroughly, spray on trees and shrubs. This helps get rid of aphids, weevils, fungal infections: late blight, powdery mildew. To disinfect premises, use a 4% NaOH solution. To do this, take 10 tbsp. l.soda is dissolved in 5 liters of water and the contaminated surfaces are treated several times.

Sale of caustic soda GOST

I will sell technical granulated caustic soda STO 00203275-206-2007, flaked caustic soda GOST R 55064-2012, caustic soda solution GOST R 55064-2012, purified soda solution GOST 11078-78. Types of caustic soda come in solid and liquid form, solid - scales, soap, liquid - solution. The name options are as follows: technical granulated caustic soda, caustic soda, sodium oxide hydrate, caustic soda, sodium hydroxide. Synonyms: sodium alkali, caustic soda, caustic soda, caustic soda, caustic alkali, sodium hydroxide. Sodium hydroxide formula: NaOH. Molar mass: 39.997 g/mol. CAS number: 1310-73-2. Chemical properties of sodium hydroxide. Sodium hydroxide is a white solid, also known as sodium hydroxide. Has the ability to attract moisture from the air. Sodium hydroxide dissolves well in water and produces a large amount of heat. Caustic soda can be purchased from our company and delivered directly to production. We will give the price including delivery, in various containers. It is used to pickle aluminum for the production of oils and oil compositions. In order to obtain white, high-quality paper, cardboard or wood-based boards, sodium hydroxide is also used. Caustic soda (caustic soda NaOH) in packaging from 25 to 60 kg in solid form at wholesale prices, and in road tankers and railway tanks, as well as in Eurocubes in liquid form. Buy caustic soda at a price for 100% of the substance, i.e. net weight per ton, as well as order delivery of the chemical to various regions of Russia and the CIS. We sell certified raw materials produced by the most famous and proven Caprolactam Plant in Dzerzhinsk; JSC "Khimprom" Novocheboksarsk; OJSC "KCHKhK" Kirovo-Chepetsk; JSC "Novomoskovsky Chlorine" Novomoskovsk; OJSC "Caustic" Sterlitamak. Buy caustic soda wholesale in Moscow and the region. Caustic soda, caustic soda, sodium hydroxide (technical) are different names for caustic soda (NaOH). This is a powerful alkali. The substance is small scaly granules of white color, without a pronounced odor. International name: sodium hydroxide. Scope of application: One of the main products of the chemical industry, pulp and paper industry, oil refining - for the production of oils, production of biodiesel fuel. There is flaked caustic soda and granular caustic soda. Where to buy flaked or granulated caustic soda wholesale or retail. Liquid sodium hydroxide (liquid caustic soda) is a colorless or colored liquid, a caustic substance. The solution is poured into railway tanks, containers, barrels or small containers. From us you can buy granulated caustic soda (caustic soda) wholesale from the manufacturer with delivery throughout Russia. Caustic soda is used in the chemical, pulp and paper industries, non-ferrous metallurgy, in organic synthesis processes, in the refining of petroleum products, in the textile industry in the production of viscose silk and in the bleaching of fabrics, in the paper and aniline paint industry, in soap making, in the production of aluminum and metallic sodium , soluble glass, alkaline batteries, Trilon B. Flaked caustic soda (flaked technical caustic soda) is a flaked mass of white color, highly hygroscopic, highly soluble in water and alcohol, formula NaOH. Flaked technical caustic soda is obtained by evaporating liquid caustic soda grade A.

Chemical indicators of caustic soda (Table 1)

| No. | The name of indicators | Brand TR | Brand RD | |

| Top grade | First grade | |||

| 1 | Appearance | White scaly mass. Light color allowed | Colorless or colored liquid, crystallized sediment is acceptable | |

| 2 | Mass fraction of sodium hydroxide, %, not less | 98,5 | 46,0 | 44,0 |

| 3 | Mass fraction of sodium carbonate, %, no more | 0,8 | 0,6 | 0,8 |

| 4 | Mass fraction of sodium chloride, %, no more | 0,05 | 3,0 | 3,8 |

| 5 | Mass fraction of iron in terms of Fe2O3, %, no more | 0,004 | 0,007 | 0,02 |

| 6 | Mass fraction of sodium chlorate, %, no more | 0,01 | 0,25 | 0,3 |

| 7 | Mass fraction of mercury, %, no more | 0,0005 | — | — |

Storage of sodium hydroxide

Caustic soda packed in polypropylene bags with a valve must not be stored in a vertical position. When stored in heated warehouses, bags and transport packages with caustic soda are placed at a distance of at least one meter from heating devices. Guaranteed shelf life is one year from the date of manufacture. Caustic soda appears as a white solid. It has the amazing property of absorbing moisture better than any sponge. If you take a piece of soda and hold it in the open air for a while, it will soon blur as it absorbs moisture from the air. Thanks to this unusual property, caustic soda dissolves very well in water, but it does not dissolve easily, and it also generates heat. Caustic soda can only be stored in a closed container. In the open air it evaporates quickly. Alkali loses its active properties 12 months after its manufacture. Caustic soda is suitable not only for cleaning pipelines and sewer drains; it can be used to destroy organic waste that has accumulated in a cesspool. International name: SODIUM HYDROXIDE sodium hydroxide, sodium hydrate, caustic soda (caustic soda), caustic soda, caustic alkali. Catalog number for sodium hydroxide CAS: 1310-73-2. Description of sodium hydroxide (sodium hydroxide, caustic soda, NaOH). Sold in white granules, coloring is allowed. The most common and long-known alkali, sodium hydroxide is hygroscopic; when it combines with water, a large amount of heat is released. Description. Preparation: Flaked technical caustic soda is obtained from purified caustic soda solution according to GOST 11078-78. Description of appearance: Caustic soda (sodium hydroxide, caustic soda, caustic soda, caustic alkali) of the TR brand (solid mercury) is a white flake mass, highly hygroscopic, highly soluble in water and alcohol.

Physical properties

White powdery substance, sometimes colorless. It can be in the form of a fine crystalline powder or in the form of flakes. Most often in the form of large crystals. The melting point is quite low - 65.1 ° C. Absorbs moisture very quickly and transforms into the hydrated form of NaOH 3.5H2O. In this case, the melting point is even lower, only 15.5°C. Almost unlimitedly soluble in alcohols and water. It feels both solid and liquid soapy.

Very dangerous in concentrated and diluted form. It can damage all the membranes of the eye, including the optic nerves. Contact with eyes may result in blindness. Therefore, working with this connection is extremely dangerous and requires protective equipment.