Bosch washing machine error codes e 21

First of all, if error F21 occurs, it is recommended to disconnect the Bosch washing machine from the network, since a common cause of the malfunction is related to voltage surges and further operation of the equipment can be dangerous.

There may be other problems not related to the power supply of the device, which can harm the machine during use. If there is water left in the washer, after unplugging it from the power supply, you must drain the water manually.

Description of the error code

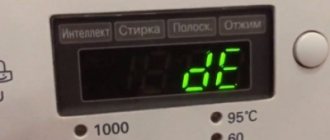

When this error occurs, the drum does not rotate when starting the equipment. When a Bosch washing machine is operating, error F21 may appear not only in the form of a code consisting of letters and numbers, but also in the form of flashing indicators located on the control panel. This happens because in some models there is no display and there is no way to display information.

With the help of flashing lights, it is not difficult to identify the problem associated with the E21 code. Three lights flash: spin speed 800 - 1000 and 600 - 800, as well as a rinse indicator. At the same time, the equipment freezes and does not respond to button presses or turns of the program switch.

Repair

To understand how a tachogenerator is repaired, you need to know what it is. The tachogenerator is a metal ring to which two wires are connected. It can be used to measure engine rotation speed. The measurement information is sent to the control module.

The tachogenerator is located on the rotating shaft. However, getting to it is not so easy. First you need to disassemble the Siemens or Bosch washing machine. How to do it?

- Turn the device towards you with the back cover.

- Remove the cover by first unscrewing the fasteners.

- Find the engine. The metal ring, which is located on its shaft, will be the tachogenerator.

The malfunction of this part is determined by how the Bosch or Siemens washing machine operates.

- From time to time the speed of rotation of the drum changes sharply.

- During the spinning process, the drum rotates slower than expected.

- When washing, the drum rotates much faster than it should.

- The laundry is not completely wrung out.

To make sure that error F21 in a Bosch or Siemens washing machine indicates a malfunction of the tachogenerator, you need to conduct a test:

- First remove the engine. To do this, you need to unscrew the bolts that hold it in place and disconnect all the wires.

- Using a special device, measure the resistance on the wires that go to the faulty part. If everything is normal, it will be approximately 60 ohms.

- Next you need to measure the voltage on the tachogenerator itself.

- After taking all measurements, it is recommended to check how securely the part is fastened. If the fastening is loose, problems with the operation of the entire device may occur. As a result, error F21 will appear on the display or indicators.

Replacing the broken element will help eliminate the breakdown. This is very easy to do:

- Remove the part cover. It is usually secured with a latch.

- Disconnect the fasteners that hold the tachogenerator.

- Remove the faulty part and put a new one in its place.

Important Details

It is worth mentioning separately about the Bosch Maxx 5 and Bosch Maxx 7 devices. Error F21 in the Bosch Maxx 5 (Maxx 7) washing machine indicates problems with the engine. In most cases, they are caused by the brushes wearing out. The error can be eliminated by replacing the brushes. If your Bosch Maxx 5 or Bosch Maxx 7 machine still displays a fault code, it needs to be reset. Here's how to do it:

- Close the door.

- Set the switch to the “Off” designation.

- Then turn it to the “Spin” program and wait until the code appears.

- Press and hold the button that regulates the number of revolutions.

- Turn the switch to “Drain”. Do not release the button for another 20 seconds.

- Release the button and return the switch to its original position.

- Repeat several times if necessary.

It is worth remembering that sometimes error F21 in Bosch Maxx 5 and Maxx 7 devices appears due to problems with the network voltage. You can eliminate it using a reset, as described above.

Error F21 in Bosch and Siemens washing machines means problems with the motor. They may be caused by malfunctions of certain parts, such as brushes or a tachogenerator. You can solve these problems yourself or by seeking help from a specialist.

Decoding fault indicators

Error code E21 stands for the inability to rotate the drum. The washing machine may try to start spinning several times; if the result is negative, code F21 appears on the control panel. Failures when trying to start the reel rotation can occur for several reasons:

Malfunction of the Hall sensor - information about the motor speed is not transmitted to the control module and it stops the operation of the washing machine.

Motor failure - a faulty motor cannot rotate the drum; the module displays an error after several startup attempts. The malfunction may occur due to wear on the carbon brushes.

Problem with the belt driving the drum - wear, stretching, weakening, misalignment or breakage of the drive belt will cause the drum to malfunction or stop rotating.

A foreign object that gets into the tub during washing can jam the drum.

Voltage drop in the network.

To identify the cause of the malfunction, it is recommended to check all points in a certain order until the problem is detected.

How to fix it?

Before resetting such an error, you need to determine why it appeared. There are several variations of scenarios that can be used to fix the failure code. Typically, troubleshooting starts from basic to complex actions, one at a time. You need to act by elimination.

Important! In order to determine the malfunction, you only need a multimeter and tools for removing the mounting bolts.

Hall sensor failure

After finding out the possible reasons for the appearance of error code F21, the question arises of how to quickly detect and fix the problem without resorting to the help of a technician.

It should be noted that there is no universal way to find a breakdown.

You need to check the above reasons in a sequence convenient for you until the malfunction is identified.

First, let's figure out how to check the Hall sensor. The first difficulty you will encounter when performing this work is the inaccessibility of the tachometer and motor of the Bosch washing machine.

You can get to these elements of the washer as follows:

- Disconnect the washing machine from the power supply,

- Pull the equipment out into free space,

- Remove the back wall of the Bosch machine body,

- Remove the drive belt

- Take photographs of the location of fasteners and wires. This is necessary so that nothing gets mixed up during assembly.

- Remove the washing machine motor.

Before removing the engine, you must first disconnect all the wiring chips from it. Next, you need to unscrew the bolts holding the motor and press on its body. It will move forward a little. Then you need to gently pull it down.

There is a tachometer located on the motor housing. It is necessary to inspect the inner surface of the Hall sensor ring. If there are traces of grease and oxide, they should be removed. Then we check the tachometer with a multimeter. If it burns out, then replace it with a new one.

Foreign object entering the drum

If you try to turn the drum by hand with the machine turned off, a foreign object will knock or grind, interfering with the scrolling. To remove a foreign object, several steps will be required.

- First of all, you should rotate the unit so that there is unobstructed access to the MCA.

- If there is a service hatch, it will need to be opened. Otherwise, you will have to resort to dismantling the fasteners and the rear wall.

- Then you need to disconnect the wires that lead to the heating element.

- The heating element itself is also pulled out from the body part. At the same time, you can descale it.

Related article: Why water from the sink gets into the washing machine

Due to perfect manipulations, a small hole will appear through which you can pull out a foreign object. This is done using a special device or by hand.

Voltage drops

This is a dangerous phenomenon that adversely affects equipment. Voltage surges may make further use of the machine impossible. Buying a voltage stabilizer will help prevent future breakdowns. It will prevent such risks from occurring.

Tachometer failure

If the cause of a malfunction in a Bosch washing machine is a malfunction of the tachometer or Hall sensor, the following procedures will be required.

- You need to unscrew the back wall of the unit and remove the drive belt. The second action will be required to ensure that nothing interferes during the repair.

- In order not to get confused in the location of the wiring with fasteners, it is recommended to photograph them before removing them.

Important! To dismantle the engine quickly, you should initially disconnect all power from it, and then unscrew the mounting bolts.

Then you can just press on the body part and lower it. With these simple steps, removing the motor will be quick and easy.

The Hall sensor is located on the engine body. Therefore, after the engine is dismantled, all that remains is to remove the tachograph and carefully examine it. Sometimes there is oxidation or lubricant on the inside of the ring. If such a phenomenon is detected, it should be eliminated. After this, you need to use a multimeter, which will report the status of the sensor.

Important! A burnt tachograph cannot be repaired.

Motor fault

Most often, electric brushes fail. This part cannot be repaired, so you will need to buy new ones. Experts advise buying original components and replacing a pair at once. The replacement process itself is easy; an ordinary user can handle it. The main difficulty lies in the correct selection of the parts themselves.

Important! In order not to make a mistake in your choice, it is recommended to remove the old electric brushes and go to the store with them.

In this way, you can use a sample to ensure that the selected part will be suitable.

Also, on a Bosch washing machine, error F21 may appear due to a breakdown of the winding turns in the motor. Due to this, there is a leak directly onto the unit body. This type of fault can be determined by using a multimeter. In most cases, if such a malfunction is detected, it is recommended to buy a new engine, since repairing the old one will cost a large sum and is characterized by numerous difficulties.

What to pay attention to

- Frame. Dark spots and paint fading are the result of engine overheating. Occurs when the windings short-circuit. One of the reasons for motor failure and error f21.

- Shaft rotation. By turning it by hand, it is not difficult to understand whether the Bosch engine is seized or not.

Collector type

- “Weak point” – graphite brushes. They wear out during use. Extreme wear of carbon tips leads to engine failure, error f21. Remove and measure length. Less than 150 mm - replace.

Bosch washing machine brushes

Only a couple. You should take 1 contact to the store as a sample.

Brushes for commutator motors of different household appliances are different, so purchase identical ones for your washing machine: similar in size, characteristics (density and other parameters).

- Carbon deposits on the collector plates and dirt between them are the cause of error f21. During operation of the washing machine, coal dust flies off from the brushes, burning on the lamellas and getting into the grooves. Cleaning with sandpaper, rinsing with an alcohol-containing solution, and drying solves the problem with the rotation of the Bosch centrifuge.

- Winding resistance. They are checked for short circuit (R=0) or open circuit (=∞). Motors of different Bosch models differ in characteristics: 20–200 Ohms is considered normal.

Bosch washing machine winding resistance Bosch washing machine winding resistance

Direct drive (inverter) type

It is still gaining popularity, but a number of washing machine models are already equipped with such motors. It is easy to identify by the absence of a belt drive.

Direct drive (inverter) type of Bosch washing machine

The design is similar to an asynchronous motor (rotor + stator), mounted on a centrifuge. Diagnostics is difficult, but you can identify some causes of error f21 Bosch yourself.

Bosch washing machine rotor Bosch washing machine rotor

- Remove the motor cover and inspect the windings. Melted varnish, smudges, bubbles, burnt areas are signs of a short or interturn circuit. The engine is changing.

- Spin the rotor. Absence or difficulty in rotation indicates a problem with the mechanical part of the motor.

Bosch error f21 is often caused by a problem with the inverter board, which converts AC mains voltage to DC to operate the engine. It is an integral part of the motor. If the mechanics are working properly, there are no visible defects in the windings, contact service. In practice, the engine changes - faster and cheaper.

Drive belt

The belt drives the drum, transmitting engine speed. If it becomes loose or worn, transmission will be disrupted. If the belt bursts or falls off the pulley, there will be no rotation at all.

What do we have to do:

- Unplug your Bosch machine.

- Remove the back wall of the washer by unscrewing the bolts.

- Check the condition of the belt. Replace if necessary.

- Select the appropriate drive for your Bosch washing machine model.

- Slide the belt onto the small pulley first, then onto the large pulley, rotating it until it fits snugly.

Solution: algorithm for identifying the cause and troubleshooting

Often error F21 in Bosch washing machines occurs due to loading too much laundry. If removing part of it and restarting it did not help solve the problem, you can proceed to the next verification step.

After freeing the machine from the laundry, you need to pay attention to whether the drum rotates when scrolled by hand. If it does not spin during washing, but rotates manually, the belt is checked. If the drum does not rotate manually, you should check the machine part for foreign objects. They can get into the space between the tank and the drum.

If after checking the cause was not found, not only the Bosch washing machine is checked, error E21 could be caused by a sharp drop in voltage in the electrical network.

Next, if necessary, the body parts are checked: tachometer, motor, carbon brushes.

Foreign object

A foreign object can damage the tank, causing water to leak and requiring costly repairs. Therefore, you need to remove it immediately:

- Disconnect the machine from the network.

- Pull the hatch cuff and check for objects.

- Remove the front panel.

- Remove the heating element.

- If necessary, remove any remaining tissue from its tube.

- Check the heating element hole for objects.

- Place the Bosch machine on its side.

- Disconnect the pipe.

Thanks to the opened hole, you can check the tank.

Hall sensor malfunction

To check the tachometer, the washing machine is disconnected from the network, after which the back panel is dismantled and the drive belt is removed.

The Hall sensor is located on the motor housing and can be removed and inspected. There may be traces of grease or oxidation on the inner surface of its ring that must be removed. Next, the sensor is checked using a multimeter. If the tachometer is faulty, it must be replaced.

Error F21 in a Bosch washing machine

When starting the Bosch washing machine, the drum does not rotate; the display shows error F 21. Let's look at what this means.

The drum may also stop mid-wash.

Electromechanical BOSCH CM models display an error by flashing (lighting) the speed (1000-800, 800-600) and rinse lights.

Note! Error code F21 for a Bosch washing machine is critical. You need to immediately turn off the power to the machine.

Difficulties with the engine

A thorough check of the engine will be required to determine where the problem is occurring. If the malfunction occurs due to wear on the carbon brushes, it is enough to replace them. In case of other engine breakdowns, in most cases, the entire engine is replaced.

After fixing the problem, you will need to reset the error. To do this, turn the program switch to the “off” position and set the selector to “spin”. After this, wait for the code to appear on the control panel and hold down the drum speed switch button for a few seconds. Then set the switch to the “drain” position and hold down the speed switch key again. The appearance of a characteristic sound signal and the simultaneous turning on of all lights for a short period of time indicate a successful reset.

We managed to determine the cause of E21, but still need a part? Order from Samodelkin: inexpensive, fast delivery, guarantee.

How can I prevent future breakdowns?

prevent problems that provoke error e21 :

- Before loading into the drum, the pockets of dirty clothes must be checked for the presence of foreign objects, buttons and other small accessories are checked for strength.

- Small items of clothing, as well as underwear and socks are washed in special mesh bags.

- Connecting the washing machine through a special voltage relay will help avoid breakdowns caused by a sudden surge in voltage in the network.

Strict adherence to all the manufacturer’s recommendations specified in the passport of the household appliance will help you operate the washing machine for as long as possible without repair.

Bosch washing machine code E21 - what is it?

The Bosch washing machine signals the impossibility of rotating the drum with error f21 (e21) on the control panel display.

In a situation where the washing machine is not equipped with an information display, you can find out about the problem that the drum rotation is blocked by the blinking indicators:

If error e21 occurs, the washing machine should be turned off immediately. Otherwise, when diagnosing and fixing the problem, there is a high risk of electric shock.

Control module failure

If this element malfunctions, absolutely any error may appear, not just E18. After all, it is he who is responsible for the functioning of the washing machine as a whole.

The Bosch machine control module contains many radio elements. Failure of one of them leads to a stop in the operation of washing equipment. This module is repairable. However, it is not recommended to undertake its repair yourself. It is better to entrust this work to a master. Otherwise, you may permanently break the part. And it has a fairly high cost.

Why does it appear and what to do?

Error e21 can be triggered by:

Diagnosis of the cause of error E21 begins with the simplest possible faults, which will not be difficult to fix with your own hands.

Checking the drum

In a situation where attempts to independently resolve error e21 were unsuccessful, a service center technician will help restore the functionality of the Bosch washing machine. It is enough to leave a request by phone or on the website of a specialized company (the coordinates are easy to find on the Internet). The application indicates the model of the washing machine, the year of manufacture of the device, and the essence of the problem.

A professional technician will carry out diagnostics, quickly determine the cause of error E21, and eliminate the malfunction. On average, the cost of services to eliminate the E21 error varies from 1,500 rubles. up to 5000 rub. (urgency of the order increases the amount due).

To avoid falling for scammers, before leaving a request, it’s a good idea to find reviews from those who have already used the services of the selected specialist. You cannot pay for repairs that have not yet been completed! Otherwise, there is a high risk of being left without money and without a repaired washing machine.

Error E21 - when you can fix it yourself

The appearance of an error does not always mean that the SMA is broken. Perhaps the cause of the error is different, and you can fix the code yourself.

- The socket is acting up. Carefully inspect the outlet and plug. You may notice carbon deposits or smell something burning. In this case, you need to replace the outlet with a new one yourself or contact an electrician.

- Low voltage in the network. There is probably unstable voltage in your home. Contact your energy supply company or, if sags occur periodically, install a voltage relay.

- The control board is stuck. It needs to be rebooted. To do this, disconnect the machine from the power supply for 10-15 minutes. If there was a one-time module failure, after rebooting and resetting the error, the code will disappear.

Note! Most Bosch machines require a manual reset of the error after eliminating the cause of its occurrence. How to do this - read our article “How to reset an error in a Bosch washing machine.”

Adviсe

Often code e21 is a signal that the washing machine drum is overloaded . To understand whether this is true, you need to unplug the power cord from the outlet, manually drain the water, reload the drum, and start a new wash cycle.

After the cause of error e21 has been eliminated, additional steps must be taken to reset the error. How to reset the code? To do this, set the selector switch to the “Off” position, then “Spin”, hold down the drum speed switch button for a few seconds, set the selector knob to the “Drain” mode, and press the speed switch button again for a couple of seconds.

What does error F21 (e21) mean on a Bosch washing machine, how to detect the problem and fix it?

The washing machine is loaded, the working cycle is started, but at some point the drum stops and the washing machine, by flashing indicators or the alphanumeric code e21 (f21), begins to signal a malfunction.

We’ll tell you in more detail what error code F21 means on a Bosch washing machine, where to look for the cause of the problem and how to fix it.

What does the error mean and why does it appear?

Error E21 most often occurs when trying to start a Bosch washing machine. The unit begins to rotate the drum only in one direction or does not rotate it at all, and then issues an alphanumeric code.

The error indicates that there is a problem with the engine electrical circuit. The following reasons can cause the E21 problem:

Some of the listed faults can only be eliminated with the help of a service. But some problems can be easily fixed with your own hands.

On some models of Bosch washing machines, the error is displayed as code F21

Attention! Sometimes E21 appears only at the moment of switching to spin mode, and washing and rinsing proceed normally.

Possible faults requiring repair

If you are unable to resolve the F21 code on your own, we recommend disconnecting your Bosch from the power supply and calling a technician. He will conduct diagnostics and determine the exact cause of the error. Here is a list of the main breakdowns that cause error E 21 to come on, and the cost of fixing them.

| Signs | Breaking | Repair or replacement | Cost* (work only) |

| Bosch does not spin the drum at all or cannot spin. Perhaps the SMA is sparking. On the screen there is code E21. | Motor brushes. The graphite brushes in the motor are responsible for transmitting voltage from the stator to the rotor. As their length decreases, the motor power decreases. With a non-critical reduction in brushes, Bosch can spin the drum during the wash, but does not gain speed during the spin cycle. When the length of the brushes becomes less than 1 cm, there is no rotation at all. Brush abrasion is the most common cause of error F21 in Bosch. | The brushes must be replaced with new ones. | from 1400 rub. |

| Code 21 appears immediately when turned on, but the drum does not rotate. | Control unit firmware failure. All work programs are stored in it. Most often, this problem occurs after power surges. | The technician removes the memory chip from the control unit, reprograms it and solders it in place. | from 2000 rub. |

| A Bosch washing machine may not spin the drum at all or only rotate in one direction. The error first appears after filling with water. But in some cases it can occur at any stage of the program: in this case, the cycle breaks down. | Control block. The radio elements in the motor circuit fail or the tracks on the board burn out. The motor control triac or reverse relay is often faulty. | The technician diagnoses the control unit and:

| |

| The Bosch machine does not rotate the drum and shows an error. | Tacho sensor. It determines the rotation speed of the motor and is located on the rotor. Often the tachometer coil burns out or the magnet becomes unscrewed. | The technician “rings” the tachometer and, if it is burned out, replaces it with a new one. If a magnet comes loose, the technician screws it back on. | from 2000 rub. |

| The washing machine takes in water, after which it writes error E21 or F 21. The drum does not rotate. Sometimes the SMA can knock out an RCD or machine gun. | Motor. There is probably a break or short circuit in the rotor or stator windings. Sometimes the reason is a breakdown in the body. | The technician inspects the motor and, based on the type of failure, repairs it or replaces it with a new one. | |

| The Bosch washing machine makes loud noises: it knocks, rattles and the drum does not rotate well. The error can occur both during washing and during rinsing or spinning. | Foreign object in tank. Clothing accessories (a bra wire, a zipper catch, etc.) or things from pockets (coins, a toothpick, etc.) got there. They prevent the drum from rotating and cause an error. | The foreign object must be removed from the tank. You can do it yourself or order it. | from 1300 rub. |

| The machine makes a lot of noise during the spin cycle and does not spin. It is possible that the drum does not rotate at all. | Bearing wear. During long-term operation of the SMA, due to vibrations, the tightness of the seal is broken. Moisture gets into it, which leads to bearing corrosion and destruction. If the process has just begun, Bosch rattles only during the spin cycle. When the bearings are destroyed, they completely block the rotation of the drum. | It is necessary to replace the bearings and oil seal with new ones. | from 3300 rub. |

| Error F21 occurs periodically. Sometimes the machine goes through the entire cycle normally, other times an emergency code is displayed. | Plug and/or power cord. Due to wear of the plug and/or cord, the phenomenon of “contact bounce” occurs when, when the circuit is closed, uncontrolled closing and opening of contacts (electrical breakdowns) occurs. | The technician “rings” the Bosch CMA plug and cord and, based on the diagnostic results, replaces it/them with a new one/s. | from 1400 rub. |

| Bosch starts the wash, draws water, but the drum does not spin, and the machine displays code E 21 or F 21 on the display. | Broken wiring or contacts in the motor circuit. Probably, due to vibrations, the contacts became loose/burnt out or the wiring was damaged. In the private sector, wires can be chewed by mice and rats. | The master “rings” the circuit, and, based on the nature of the malfunction:

| from 1500 rub. |

List of codes and troubleshooting methods

The devices are represented by such series as Maxx, Logixx, Classixx, Avantixx and Home Professional . The fault codes displayed on the sensor of a Bosch washing machine are, in most cases, the same in all series.

No. 1. Problems with the machine door

Due to the loading hatch not being closed tightly enough, code F01 . Immediately make sure that the door is slammed tightly, rearrange the laundry so that it does not interfere with the correct fixation of the hatch (you must clearly hear a click when closing).

The problem may also be a faulty hatch handle, door parts, guide part or locking element. If they break, they must be repaired or replaced.

To correct error F1, it is necessary to check the functioning of all parts of the hatch: fasteners, handle, corresponding lock mechanism and adjacent parts

Code F16 indicates that the wash does not start due to the hatch not being closed. In this case, you will need to slam the door and restart the program again.

If the error does not disappear, check the functionality of the door, locking tongue, locking element and, if necessary, update the damaged parts. Check the wiring.

Often problems are found in the door handle. It should be carefully disassembled using a screwdriver and repaired, replacing damaged elements

F34 flashes on the screen . This is one of the critical errors, so turn off the device immediately. There may be two root causes. The first is that the door does not close, and the second is that the door does not automatically lock.

In the first case, the door does not close or open again, or the hatch cannot physically close (something is in the way). This happens due to the door being skewed due to deformation, or the locking hook does not fit into the special hole, or when the plastic guide is worn out.

To identify the causes of the door malfunction (F34), it is necessary to disassemble it and carefully inspect it, also check the bolts, hinges and locking system

In the second situation, the problem is either a broken blocking element, or a clogged blocking device (debris or small objects have gotten in), or a broken control module (which happens very rarely).

You can fix it by turning off the device. Next, check the lock, hinges and the door itself, the locking system and its wiring. Then, if necessary, parts are repaired or replaced. The module is checked, and if it is burnt out, a replacement is needed, if the software has crashed, then it needs to be reflashed.

Critical error F36 indicates a malfunction of the locking system (broken lock). The reason may be an open hatch or a lack of locking. Restart the machine, check that the door is closed tightly, look at the wiring, hinges, lock and control module. Renew or repair parts.

One of the root causes of error F36 is a faulty blocking element. The part should be carefully inspected, then, if necessary, repaired or replaced

Code F61 indicates that the door has an incorrect signal (it is both open and closed at the same time). This error is critical, so press ON/OFF immediately.

The reason could be a module freeze. To resolve this, do not turn on the device for 30 minutes. At this time, call a technician or check the module, hatch lock (locking mechanism) and wiring yourself.

No. 2. Errors due to water supply problems

Code F02 appears on the display when there is no water. This error can be caused by:

- breakdown of the board, inlet valve or pressure switch;

- incorrect installation of the device;

- the tap supplying water is closed;

- lack of water or pressure in the water supply;

- clogging of the filler filter;

- does not close tightly enough or the hatch does not lock.

You can fix these problems yourself. First, reboot your controller. If this is the problem, then you should rewrite the software or replace the board; in this case, use the services of a specialist.

If not, then you need to check that the machine is connected correctly; the hose should not be pinched. Check the water pressure in the system and the handle of the tap that supplies it.

Clean the inlet filter (rinse the mesh of the hose intended for water supply under pressure). The filter itself is located at the connection point of the inlet hose, at the top of the machine.

Inspect the inlet valve, then the blocker and repair if it is faulty. Check the pressure switch (pressure sensor) and the wiring leading to the sensor for damage. Carry out the same actions with the door.

Code F03 is displayed if there are difficulties draining water and there may be several reasons for this error, namely:

- the garbage filter or sewer pipe is clogged;

- the drain hose is clogged or deformed;

- critical stretching or rupture of the drive belt;

- drain pump malfunction;

- problem with the module.

How to eliminate them? First, you should check the drain filter and clean it if necessary. If this does not help, inspect the drain hose for kinks or improper placement.

Reinstall it as needed or clean it with special chemicals. Check, correct or replace the drive belt, and do the same with the pump. It is better to entrust testing of the main board to a specialist.

To correct error F03, you need to clean the water drain filter; to do this, you need to remove it and rinse it under a stream of water. The filter is located at the bottom of the machine behind a small hatch

Code F04 indicates that water is leaking. You must quickly disconnect the device from the power supply to avoid electric shock. Then turn off the water and find the source of the leak (inspect the place where it started first), and also check the tightness of all connections.

There can be several reasons for this problem: a leak in the hose, the drain filter is not screwed tightly, problems with the dispenser, the rubber cuff has torn, the filler pipe in the tank of the device or the tank itself is damaged, the inlet valve pipe has failed, the drain pump is worn out.

A common cause of leaks is damage to the hose or a loose connection to the unit. If damaged, the hose must be replaced

To eliminate it you need to:

- inspect the hose, renew if damaged;

- screw the filter plug tighter;

- take out the washing powder bin, rinse, dry, and replace if damaged;

- if the seal is not too damaged, try to repair it; if they are worn out, replace them with new ones;

- in case of serious damage, replace the cuff;

- If the tank malfunctions, it should be replaced.

Code F17 occurs if water does not flow. On some models this error may appear as E17 .

Its occurrence can be triggered by:

- closed tee tap supplying water;

- water pressure less than 1 atmosphere;

- clogged filter or water supply hose;

- the electronic controller or intake valve does not function;

- The pressure switch stopped functioning.

Removing the error is simple: open the water supply tap, after which the cycle will end, and the pump will drain the water in a couple of minutes. Reboot the electronic board, and if it is the problem, replace the unit or reflash it.

Clear the strainer and any blockage in the hose if there is one. Check the voltage on the valve coil, as well as the pressure switch, sensor controller and its pipe, change parts if necessary.

When the machine does not draw water for some reason, you should check the inlet valve and water supply hose for damage.

When the water in the washing machine does not drain at the right time, code F18 .

Signs and types of errors:

- water may drain slowly due to a program failure, for the same reason the machine freezes before draining;

- irregular drainage (every other time);

- after rinsing there is no drain;

- The laundry is not spun.

This happens due to a clogged “garbage” filter, incorrect installation of the water drain hose (it could be bent), if the pump does not rotate or the controller malfunctions.

Error F18 will appear on the display if the Bosch washing machine has stopped draining water. First, carefully check the water drain hose, then see if the siphon to which the hose is connected is clogged

To solve the problem, reboot the washer. If it doesn’t help, then turn off the power, remove the filter and clean it from the blockage.

Then perform the following steps one by one:

- the hose must be straightened and installed correctly; check the blades (threads or debris could be wrapped around them);

- if the pump is faulty, then replace it;

- check the control unit;

- inspect the wiring connecting the module to other elements; to fix such problems, it is better to call a technician.

When the Aqua-Stop function is activated, code F23 . You immediately need to disconnect the machine from the network, tighten the valve, drain the water, and check for leaks.

The simplest version of the AquaStop system is a pan with a float that shuts off the water supply if a leak is detected.

Also inspect the connecting circuits for breaks, the inlet hose and pipe, the hose with the solenoid valve, and the pressure switch. All of these components need to be replaced in case of breakdown.

If the turbidity sensor (code F25 ) does not work, the program will complete the wash without rinsing. The reason may lie in the formation of limescale on the water sensor, a faulty pressure switch, clogged filler or drain lines if dirty water comes in.

The fill and drain filters need to be cleaned. Replace the aqua filter (turbidity sensor) or descale it. To flush the system, run a wash without any laundry at the highest water temperature. Contact a plumber or install a flow filter yourself. Replace faulty parts.

When code F29 , it indicates that there is no water flowing through the flow sensor. There may be several reasons: the machine is installed incorrectly, the hatch is poorly closed, there is no or weak pressure, the filter mesh is clogged, the fill valve or pressure switch is broken.

First, check the hatch, pressure and straighten the hoses. Then look at the filter, valve and pressure sensor. After eliminating the root cause, the draining process will begin after 5 minutes, then you can resume the interrupted cycle.

Code F 29 indicates problems with the flow sensor; in this situation, a comprehensive check of some machine parts is required

If the permissible amount of water is exceeded (fault code F31 ), the wash cycle will not complete until the water is drained. This is a critical error; if it occurs, you must immediately unplug the device from the outlet.

It occurs due to illiterate installation and connection of the device, due to a violation of the location of the hose. The pressure switch, water intake valve, pump or controller turn out to be faulty.

Error 31 often occurs due to improper operation of the pressure switch. To troubleshoot problems, you need to test the device and update it if it breaks

To fix it, normalize the position of the hoses, if necessary, install a special valve on the drain hose and turn on the drain mode. If this does not help, then reinstall the machine correctly or check and replace the faulty part.

No. 3. The heating process is disrupted

If there are problems with water heating, code F19 flashes. The reason may be low voltage or voltage fluctuations, scale formation, burnt-out heating element, malfunction of the temperature sensor or board.

The heating element is the cause of several errors in the operation of Bosch machines. It must be carefully removed and cleaned or replaced with a new one.

To resolve this, reboot the device and normalize the voltage. If there are no changes, then it is necessary to check and update the thermostat, heating element and wiring to it. In some cases, cleaning the heating element from scale helps.

The diagram shows the location of the heating element in a Bosch car and what actions need to be taken to remove it painlessly

Code F20 informs the user that unplanned water heating has occurred (the temperature is higher than the set temperature, things are shedding, the device is getting very hot).

The error can be caused by a program failure, a broken thermostat, or a failed heater relay (heater). Each element must be checked and replaced, having first disconnected the device from the network.

When the NTC sensor (thermistor) fails, F22 .

There may be several reasons:

- the connection to the water supply is broken - not enough water circulates in the system, so there is no heating;

- low voltage in the electrical network or its absence;

- breakdown of the controller, its wiring or electric heater;

- incorrectly selected washing program;

- failure of the level sensor or thermistor.

To resolve the problem, check the inlet hose and its location. Then - the electronic board; the element may need repair or replacement. Module wiring or electrical circuit may need to be repaired due to burnt contacts. Check the heating element and the functionality of the temperature sensor, update if they break.

Often, the failure of the machine to work and heat water is associated with a violation of the insulation of the internal wiring of sensors and system components. In this case, you will need to disassemble the unit and replace damaged wires.

Test the operation of the pressure switch and if it is broken, replace it. It makes sense to connect a stabilizer that will “save” you from power surges.

Code F37 means that problems with water heating are associated with a breakdown of the NTC sensor. In this case, the sensor itself or its wiring leading to the board could break.

Please note that there are different sensors: bimetallic, gas-filled, electronic. Each of them requires different repairs. Immediately rule out a system failure and check the thermistor, wiring, control board, then replace the necessary parts.

The location of the temperature sensor in a Bosch washing machine is shown and how it can be reached for replacement or inspection

A thermistor short circuit will appear as F38 on the display. You should immediately turn off the machine from the network. The cause of the accident may be a breakdown of the thermistor, voltage surges, or a malfunction of the module. You should inspect the NTC sensor and check the voltage, first turning off the washing machine from the network.

No. 4. Problems with sensors

If F26 , then the pressure sensor (pressostat) in the machine may be broken, which protects the device from voltage problems; it is also needed to measure the amount of water in the tank.

This is a critical error, you need to fix it like this:

- turn off the washing machine for 30 minutes. (ON/OFF button) to reboot it;

- check how the pressure switch functions;

- check that the connecting circuits are not broken.

If this sensor is not configured, F27 . In this case, you need to restart the machine, check the pressure switch, wiring, water pressure and inlet hose. If necessary, correct problems or replace broken parts.

When the tank does not fill with water, F28 . This happens due to a faulty flow sensor. First, reboot the system. Then diagnose the flow sensor, fill valve, and also check the wiring for faults (debris has entered, no pressure). Update faulty parts.

If the flow sensor fails and it produces too high, or, conversely, low value, then the code F60 can be seen on the display. The cause may be low or high pressure in the water supply, problems with the fill valve, lack of water in the system, failure of the level sensor or circuit board, breakdown of the blocker or heater, or problems with the drain pump.

If the reason for the washing machine failure lies in a malfunction of the inlet hose and valve, they need to be replaced with new parts

Check that the wiring, flow sensor, and filter in the fill valve are functioning properly. If there is a problem with the plumbing, it can be easily solved on your own or by inviting a specialist. In other situations, it is necessary to check all specified parts and replace them.

Code F59 appears when the 3D sensor is not functioning and a measurement error occurs. The reason is a module error, the electronic board cable is coming off, the sensor is burnt out or faulty.

In such a situation, you must first reboot the device, then check the correct position of the magnet, wiring and 3D sensor of the device, module and troubleshoot.

The reason for the malfunction of the sensor system may be a failure in the connection to the washing machine’s control unit. You can fix it yourself

No. 5. Incorrect drum rotation

Unrealistic engine speed that cannot be controlled causes code F42 . The error is critical, so reboot the device using the Power button and check the module.

F42 also occur due to a damaged TACH sensor (controls the speed of the device), due to a breakdown of the engine, or a malfunction of the triac on the board. The problem can be corrected by replacing the speed sensor, repairing the engine and its wiring or a section of the electronic board.

If the motor is blocked and the drum does not rotate at all, then code F43 . This critical error occurs due to laundry getting stuck between the drum and the tub.

To fix it, you need to:

- restart the machine;

- see if the laundry loading limit has been exceeded;

- check the serviceability of the TAKH generator;

- Verify that the module and wiring are functioning correctly.

This error requires immediate repair. Therefore, check the drum and internal parts of the device, and replace them if necessary.

If the problem is in the motor, then you cannot use the washing machine, as this can cause a short circuit and fire. If error F43 occurs, immediately unplug the machine to avoid an accident.

When there is no rotation only in the opposite direction, F44 . The error is critical, so you need to enable a restart, and then check the module and parts responsible for rotation.

A malfunction can be caused by a failed triac, an imbalance of the drum, an overloaded tank or a broken reverse relay. It is necessary, after testing first, to replace the triac on the board, relay or controller.

No. 6. Engine malfunctions

Code F21 hides a motor breakdown, since the rotation of the drum depends on it. When you see this code, you must immediately stop washing, unplug the device, drain the water, remove the laundry, wipe the inside of the drum and call a technician.

The following may be to blame for this error:

- too large load of laundry;

- stretched or damaged drive belt;

- control board failure;

- breakdown of the TAKH sensor, worn out engine brushes;

- breakdown of the motor itself;

- an object stuck in the tank, blocking rotation;

- The bearings are worn out and leaking.

To resolve, check the drive belt for breaks - it may need to be corrected or updated.

The integrity of the drive belt is the key to the smooth operation of the washing machine engine. It should be checked for damage and tears.

Inspect the wiring and control unit, wires and contacts - sometimes the module may need to be replaced. If the machine operates on a commutator rather than a direct-drive motor, then its important part – the carbon brushes – could be damaged. They cannot be repaired and require replacement.

Carbon brushes are one of the key parts of the Bosch machine engine; if any faults are detected, replace them with new ones.

Next, test the motor, repair it or replace it with a new one if necessary, disassemble the washer body and remove the foreign object, renew the bearings.

If there are problems with the operation of the motor, a critical error E02 . Turn off the device immediately, otherwise there is a risk of fire in the wiring or motor and call a technician. He will check whether the graphite brushes of the engine, the motor, its resistance, connecting contacts, key modules, as well as engine modules, and the TAKH sensor are in good condition.

No. 7. Software malfunctions and system protection

Code F67 indicates a breakdown or overheating of the card (controller). Reboot the machine immediately. If the code appears again, then there may be an error or failure in the card encoding between the power and control modules.

It is necessary to call a specialist to replace it with a new working part or reprogram the module. Repairing the card is possible if the processor is fully functional.

Thanks to the control module, all the electronics of the washing machine work; sometimes it can freeze. Therefore, if any errors occur, first reboot the system by turning it off for 30 minutes

Code E67 is visible if the washing machine module has failed. The error may be displayed due to unstable voltage, faulty wiring or network fluctuations, breakdown or burnout of key parts (capacitors, triggers, fuses) or erratic pressing of control panel buttons.

If the module overheats, to reboot it, unplug the machine from the outlet for 30 minutes. When the voltage stabilizes, the code should disappear. Those with technical skills will be able to independently repair the card and replace the board, reprogram the controller, otherwise call a specialist.

To repair the controller yourself, you need to have certain technical skills. If you are not confident in your abilities, then call a specialist

When the machine's functional protection is triggered, F63 . The error may occur after a short circuit. The cause may be a software malfunction or a processor failure.

To eliminate it, you need to reset the program by turning ON/OFF, then see how the module works. Code F63 is not displayed - everything is fine. Otherwise, you should call a specialist to conduct a full diagnosis and find out the cause of the problem.

Critical error F63 occurs if functional protection is triggered. If our advice does not help, you should call a specialist to diagnose the problem.

There may be several such reasons. Most often, the machine can knock out traffic jams or an automatic machine. This occurs due to a breakdown of the heating element, the “Start” button or the engine. The root cause of element failure lies in high humidity or oxidized contacts; they are the ones that knock out the plugs or the machine.

If the machine does not start and F40 , this means that there has been a failure in the power supply. In simple words, the washing machine does not start.

This error may occur when:

- voltage below 190 W;

- if traffic jams or a machine breaks;

- RCD is triggered;

- the cord, plug, socket is broken or the interference filter is damaged.

The cause may also be a breakdown of the start button or board.

In such cases, you should consult an electrician to troubleshoot the problem, or check and replace the parts yourself.

Bosch washing machine - error F21

If error F21 appears in a Bosch washing machine, technicians advise immediately disconnecting the machine from the electrical network. After this, call a specialist who will fix the problem. It is unsafe to search for and fix the problem yourself, as there is a chance of getting an electric shock. But don’t get scared ahead of time. Let's find out what this error means and what needs to be done when it occurs.