#lg-washing-machine-errors

Published: 10 Jan 2021

You loaded the laundry, selected a program and pressed “Start”. The LG machine took in water, but did not turn the drum and gave an LE error. If you have a direct drive model, you may have noticed that the drum is jerking as it tries to turn.

Usually the LE error lights up at the beginning of the program, but occasionally it can appear during a spin or rinse.

Error interpretation

The LE error tells us that for some reason the motor has blocked. Typically, this error indicates that there are some problems in the electrical network (external or internal), which is why the motor is blocked.

LE and 1E errors should not be confused; they have completely different meanings.

See also -

What does the UE error mean on an LG washing machine?

E1

Failure E1 appears in the event of a malfunction in the liquid filling system. The presence of a fault does not allow washing to be performed.

Water leak

The average time it takes to fill the tank with water is 4-5 minutes. If during this period the water does not reach the required level, there is a high probability of leakage.

Causes

The causes of failure often lie in the breakdown of internal mechanisms. The error is mainly related to the drainage system and the leakage sensor.

Depressurization of elements of the filler and drain system

Depressurization occurs due to damage to the elements. In this case, it is necessary to replace or restore integrity.

Leak control sensor

Lack of leakage control leads to disruption of the drain and fill of water. A broken sensor must be repaired or replaced.

In what cases can you fix it yourself?

- The door is not closed tightly. An unlocked door does not complete the circuit, which tells the equipment that the program cannot start. Try opening the hatch again and pressing it firmly until you hear a characteristic click;

- UBL contacts have been sent. To check the serviceability of this element, you need to remove the top cover from the washing machine and check the wires and contacts. If they just move away, you can reconnect them yourself. However, if the wire breaks or is chafed, it is better to contact a specialist;

- Failure in the control unit. Sometimes it happens due to power surges or other reasons, which indicates possible equipment overload. To debug, you need to disconnect the washing machine from the power supply for about a quarter of an hour. During this time, the electronic controller must resume its functions;

- Machine overload. Most often it occurs when using the “Silk”, “Wool”, “Hand Wash” modes. The LE error appears during the spin period, when the appliance is unable to cope with the weight of the laundry exceeding the permissible limit. You can resume work by stopping the program, removing some of the laundry into a separate container, or restarting with the spin operation. The remaining items should be placed for the same operation in the second run;

- The drum is blocked by foreign objects. During the washing process, a button, bra wire, or other small hard part may come off, keys, keychains, and similar small items that were not removed from your pockets in advance may fall out. They can get between the drum and the housing close to it and mechanically block the drum. Turn off the machine and try turning the drum in different directions by hand. If the drum does not rotate, then it is necessary to disassemble the tank and remove the blocking object.

- Unstable voltage of the electrical network. For correct operation of the equipment, a stable voltage is required, so if it decreases for a short time, the machine may respond with an LE error. A voltage stabilizer will help fix the problem.

Important:

The PF error accompanying problems with the LE code indicates the presence of power supply failures. Even when eliminating errors by rebooting the machine, it is better to take care of purchasing a stabilizer.

Tachogenerator failure

This is the device that rotates the engine. The Hall sensor is called differently in honor of the inventor. Located on the electric motor shaft. If it breaks, the machine begins to hum loudly, and the drum rotates faster than it should.

Reasons that could cause a breakdown of the tachogenerator:

Follow these steps to repair the tachogenerator:

Make sure the device is securely fastened.

If the bolts securing it are loose, this may indicate various malfunctions in the operation of the device.

Malfunctions requiring repair

There are some types of breakdowns that will be technically difficult to fix using ingenuity and available tools, and it is better to entrust this work to a specialist. The table shows malfunctions that could cause the LE error to appear on the display of an LG washing machine.

| Breaking | Signs | Causes | What to do |

Mechanical damage to the handle or lock | It is impossible to close the door of the device; an unusual shaky movement of the hatch handle is felt in your hand. Plastic or metal parts have broken off. | There is mechanical damage in the lock or handle, contact is broken in the UBL circuit. | Replace damaged parts of the lock system, handle or control unit wires. |

UBL wiring is damaged | The door does not lock, despite the absence of visible damage. | Most likely, a contact break occurred in the wiring due to rubbing of the wires, disconnecting the contacts in the UBL block. | Use a multitester to check the wires going to the UBL device. If the wires are worn out, the cable must be replaced. |

UBL broke | The hatch closes, but does not lock. | UBL is broken. | Replace the UBL with a serviceable one. |

Tachogenerator (speed sensor) faulty | There is no drum rotation, which is accompanied by a strong noise from the equipment. | The tachogenerator that controls the motor speed in the washing machine has failed. Most likely one of the Hall sensors in it has broken. | Check the serviceability of the tachogenerator, its resistors and Hall sensors. Replace broken parts. |

Motor winding burned out | The washing machine does not start at all, the drum does not spin. | One of the motor windings burned out. | Depending on the nature of the fault, it may be necessary to replace the entire motor or just the stator if only one winding is damaged. |

The control unit is faulty | The washing process stops at any stage, regardless of the type of program currently running. | There is a defect in the electronic controller (control module). | Remove the control module and check the extent of its malfunction. If possible, this part is repaired if resistors are burned out, other individual elements, contacts and tracks require soldering. In case of severe melting or breakdown of the processor, a complete replacement of the unit is required. |

What does the code that the LG washing machine produces mean?

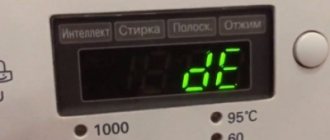

The DE error is one of the most common. Many owners of LV washing machines encounter it. It can appear at any time:

- during washing;

- when rinsing;

- during the spin cycle.

When I try to restart the program, the error occurs again. In this case, the door of the device is not blocked. Sometimes the error is coded with the letters dE1, dE2 or DOOR.

Not all LG washing machines are equipped with a display. If it is not there, then the DE error will be indicated by the simultaneous flickering of all indicators: temperature, wash and rinse.

What it is? Error DE stands for door lock. It means that the hatch is not fixed, which means that the device cannot continue to operate.

Motor winding problems

This is most often associated with the stator and rotor windings. If a short circuit occurs, the winding may break. In this case, the engine stops or reduces speed.

When the engine stopped, there was most likely a break in the stator windings, which could cause the motor housing to overheat. When the engine heats up to a temperature above 90ºС, the temperature sensor should trigger, stopping the engine. From now on, make sure that the engine of the machine does not heat above 80ºС.

To check if the winding is broken, use a multimeter as an ohmmeter. In different positions of the shaft between the lamellas, the resistance of adjacent elements should be the same - from 0.1 to 0.4 Ohm.

A short circuit in the motor winding may indicate an insulation failure. In this case, you will need to change the entire motor, or create the winding again, but this is difficult. A short circuit in the engine can also cause other problems.

Causes, diagnosis, solution to the problem

Before embarking on a serious diagnosis of the LV, you can try a reboot. To do this, unplug the washing machine for 20 minutes and then turn it on again. If there was a failure of the control module, then after switching on again the situation may level out.

Drum overload

The module is the computer of the washing machine. He is responsible for the process of all selected programs, controls washing, rinsing and spinning. The module is a board that can be easily removed, repaired, and replaced in case of malfunction.

The module may fail for several reasons:

Inspect all elements of the module for integrity and whether all connectors are connected correctly. In case of malfunction, replace the part or contact a service center.