Whirlpool washing machines are reliable appliances that enjoy well-deserved consumer trust. But, as with any household appliance, breakdowns and malfunctions can occur with them.

In such cases, the self-diagnosis system displays an error code on the display. In some situations this may be F08.

We will tell you what error F08 means in a Whirlpool washing machine in this article.

Possible faults requiring repair

If “rebooting” the module did not help, and error F08 still appears on the display of your Whirlpool, then we are talking about a breakdown of the washing machine. According to the experience of RemBytTech specialists, the following components fail in Whirlpool with this code.

| Signs | Breaking | Repair or replacement | Cost* (work only) |

| The Whirlpool machine writes error F08 immediately after turning on the program or takes in water, spins the drum several times and goes into error. In some cases, the washing machine may knock out the machine or RCD. | heating element (heater). The heating element is burnt out or breaks through to the housing. Most often, heating elements fail due to scale (it is formed from impurities in tap water, powder residues and lint from things). Trying to heat the water to the required temperature, the “overgrown” heating element works “for wear and tear”. As a result, either the spiral burns out or its body burns out. In the second case, the machine knocks out the plugs. |

*Prices are given only for the work of the master. Spare parts are paid extra.

If your Whirlpool washing machine has issued an emergency code F08 and is no longer washing, it’s time to contact the professionals. Call RemBytTech:

We arrive promptly: within 24 hours from the date of request for repairs. We carry out all work at the client's home. We confirm the quality with a warranty card for up to 2 years. We will do everything to ensure that your life returns to normal, and that your equipment delights you with trouble-free operation for many years to come!

Calling a specialist: where to find and how much to pay a specialist?

Carrying out diagnostics and repairs of washing equipment cannot always be done on your own. If you lack skills or lack time, a specialist from a specialized company can help. Depending on the complexity of the breakdown and the company’s pricing policy, the cost for the work performed is determined.

In the capital, Whirlpool repair prices on average are as follows:

- wiring repair – from 2000 rubles;

- Firmware recovery – from 2500 rubles;

- repair of the control unit – from 2500 rubles;

- replacement of a temperature sensor – from 1600 rubles;

- replacement of heating elements - from 1800 rubles.

After the repair is completed, the operation of the washing machine is tested, and the technician issues a guarantee. In order not to make a mistake in choosing a specialist, you should seek help from a company that has been operating on the market for more than one year and has a good reputation.

How to fix error F08 on a Whirlpool washing machine

Whirlpool automatic machines are distinguished by their build quality, reliability and high washing efficiency, and serve their owners faithfully for a long time. However, not a single household appliance is completely immune from breakdowns. For example, a situation may occur in which the user starts the washing process, the machine starts working normally, but after a while it stops and displays error code F08. We’ll talk further about what this designation means and what actions to take to fix the breakdown.

What would that mean?

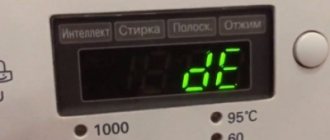

A similar code may appear on the digital display at any washing step. It indicates that the temperature of the water in the tank does not correspond to the parameters specified by the program. This kind of malfunction on a Whirlpool washing machine can indicate either a minor problem or a serious defect that only a qualified technician can handle. It also happens that the error appears due to a short-term failure, and in fact there is no breakdown.

Before you undertake repairs yourself or invite a specialist, you need to make sure that this is not a normal malfunction of the washing machine. To do this, follow these steps:

If you have rebooted the unit and made sure that even with the standard parameters of the washing mode, this fault code appears on the display, you should start looking for a breakdown. Where to begin?

Let's deal with light bulbs

The LEDs on the control panel of older Whirlpool models are located above the program switch knob. You need to count the light bulbs from left to right. So, the first indicator will be “No water supply”, the second will be “Pre-wash”, the third will be “Wash”, the fourth will be “Rinse”, the fifth will be “Water Hold”, the sixth will be “Drain/Spin”, the seventh will be “Door Open”. As for the lower ones, the eighth is considered the “Clean filter” diode, the ninth is “Service”.

It is through the blinking of some of these nine lights that the technology indicates a failure that has occurred in the system. It is necessary to count which LEDs are lit and figure out what kind of malfunction is indicated by a Whirlpool washing machine without a display.

Let's limit the range of breakdowns

The heating element, a tubular heater, is responsible for heating the water in the washing machine tank. In most cases, the F08 designation occurs precisely when the heater fails. If this is indeed the case, you need to replace the part with a new one. But a malfunction of the heating element is not the only reason for the appearance of such an error. The code can mean something else.

To begin with, you need to “weed out” the most minor and easily fixable faults. For example, diagnose a heating element, then a pressure switch or temperature sensor, and only after checking that this is not the reason, call a technician who can make a professional decision about the condition and performance of the control module of the Whirlpool automatic machine.

List of the most common breakdowns

Since a modern washing machine is a complex device, it consists of a number of components and assemblies, the list of potential breakdowns is extremely extensive. Among other things, there are a number of specific malfunctions that occur most often:

- blockages in the drain tract;

- jamming or breakdown of the pump;

- leaking tank seals;

- wear of electric motor brushes;

- belt breakage (in belt-driven machines);

- bearing wear;

- failure of the heater or thermostat;

- various failures of the control module.

Another common problem that is typical for both vertical loading machines and traditional front-loaders is the entry of foreign objects into the tank. Despite the apparent insignificance of the incident, in most cases, to solve the problem you will have to almost completely disassemble the washing machine.

Let's check the heating element

Often error F08 appears as a result of a heater malfunction. You can check the heating element very quickly. To do this, perform the following algorithm of actions (the sequence of steps described will help owners of machines with a front-loading type; for vertical machines, the manipulations will be slightly different):

Important! The heating element is located at the bottom of the machine, under a plastic casing; only by removing the protective cover can you gain access to the contacts of the heating element.

Next, disconnect the power contacts, take a multimeter and connect its probes to the terminals of the heating element, set the resistance on the device to 200 Ohms, analyze the results. If the value on the multimeter screen remains approximately the same as it was set, then the heater is fully operational. When the number 1 appears, this indicates a break inside the part and will have to be replaced. When the device displays the number 0 (or a number very close to zero), it means that a short circuit of the heater can be diagnosed, in which case you will also have to install a new heating element.

If the heater passes the first test with a multimeter, just in case, check it for breakdowns. To do this, switch the test device to buzzer mode. You will be notified that the mode has been selected correctly by a lit light and a characteristic signal that will appear when the wires are connected. Connect one multimeter probe to the heating element terminal, and attach the second to the element body. If the device does not make any sounds, everything is fine; if a characteristic squeak is heard, there are breakdowns in the body of the part, and the heater will have to be replaced.

Some troubleshooting tips

Often Whirlpool washing machine errors appear spontaneously, seemingly for no apparent reason, but many of them, in particular those related to poor drain performance, can be the result of careless handling of the device.

The occurrence of a number of malfunctions can be prevented; to do this, it is worth using a few tips. All models of Whirlpool washing machines have a drain filter. This simple device is designed to protect the drainage path from debris, threads, and scraps of fabric. To ensure that drainage errors occur as rarely as possible, you should regularly remove and clean the filter. The frequency of cleaning is indicated in the instructions for each specific model; in any case, the procedure must be performed at least two to three times a year. Caked detergent can clog the ducts inside the machine, causing the program to stop unexpectedly. It's easy to avoid this. You just need to periodically remove the powder tray and rinse it with running water. It is worth inspecting and, if necessary, cleaning the intake filter at least twice a year. This is a mesh located at the entrance to the car. The frequency of cleaning largely depends on the condition of the plumbing and the quality of water in the system. A dirty mesh can cause water to flow slowly into the drum or stop completely. After each wash, when the laundry has already been removed, you should not immediately close the door; you should leave it ajar so that the “insides” of the machine dry out. Washing with hot water helps clean the inside of the machine. It is useful to sometimes run a wash program at 95 degrees with a small amount of detergent added

This will remove dirt accumulated in the drum and pipes. It is important to monitor the condition of the drain hose. This is one of the weakest points of the car

You can accidentally step on it, place a heavy piece of furniture, or bend it too much. Kinks and blockages are a common cause of faulty drainage. The condition of the inlet hose is equally important. The appearance of kinks and cracks is unacceptable; such a hose must be replaced immediately. To avoid leaks during washing, you need to regularly monitor the condition of the hatch cuff. It must be soft, elastic and always intact. To increase the service life of the cuff, it is recommended to wipe it with a damp cloth after washing.

In order for the machine to serve for a long time and have an attractive appearance, its surface must be periodically cleaned. A damp cloth is suitable for this. If serious contamination occurs, you can use cleaning products, but they should not contain abrasive particles, otherwise the panels may be scratched, which will affect the appearance of the device.

The appearance of errors on the washing machine display is not a reason to panic, it is a signal to the owner, a reminder that the device requires care. If you keep the machine clean, periodically clean it and do not allow water to stagnate inside, errors will rarely occur, and the machine will last a long time.

Let's check the thermistor

If the heating element has been fully tested and has proven that it copes with its functions perfectly, it’s time to check the thermistor. Just, it is located between the contacts of the heater. To remove the temperature sensor, perform the following manipulations:

The temperature sensor is a small metal cylinder. After the thermistor is removed from the washer body, you need to check the resistance in it using a tester.

When the temperature sensor fails, the old part should be replaced. The thermostat cannot be repaired. If the element is fully operational, we continue the diagnostics further.

We will inspect and test the pressure switch

It is easy to provide access to the water level sensor of the Whirlpool washing machine; it is located in the upper part of the unit, directly under the lid. Very rarely the pressure switch is located at the bottom. To get to the part, carefully unscrew the mounting screws and remove the upper wall of the SMA housing, after which the algorithm of actions will be as follows:

If after an external examination no defects were identified, you need to check the pressure switch with a multimeter. The device is switched to resistance measurement mode, the tester probes are connected to the sensor contacts. If the values on the screen change, it means that the contacts are actuated and the pressure switch is working. When the resistance value remains fixed, it means that the liquid level sensor has failed.

So, when you have checked the functionality of the main elements that can trigger the F08 error code, no faults have been identified, you should invite a professional to determine the root cause of the code. After all, the problem may come from the main control board, and it is not recommended to deal with it yourself.

Compliance with operating rules

Before you begin installing and starting the device, you must read the manufacturer’s instructions, which indicate the types of functions, the programs used and how to control them.

When determining the location of a top-loading washing machine, it is worth taking care of free access to the upper space where laundry will be loaded and unloaded.

Correct installation of the device is of great importance. Leveling will prevent it from vibrating during the execution of specified programs. The floor surface must be level. Judging by user reviews, many people use special soft claw stands to ensure proper installation and reduce vibration. They are made of soft rubber and are able to absorb strong vibrations of the device during spinning.

Compliance with the basic requirements for using top-loading washing machines will increase their service life. The manufacturer recommends:

- do not exceed the weight limit for loading laundry into the drum;

- correctly select the program depending on the type of product, as well as taking into account the degree of its contamination;

- do not exceed the amount of detergent;

- Perform periodic maintenance of equipment;

- prevent foreign objects from entering the tank.

How to fix error F08 on a Whirlpool washing machine

Whirlpool automatic machines are distinguished by their build quality, reliability and high washing efficiency, and serve their owners faithfully for a long time. However, not a single household appliance is completely immune from breakdowns. For example, a situation may occur in which the user starts the washing process, the machine starts working normally, but after a while it stops and displays error code F08. We’ll talk further about what this designation means and what actions to take to fix the breakdown.

What would that mean?

A similar code may appear on the digital display at any washing step. It indicates that the temperature of the water in the tank does not correspond to the parameters specified by the program. This kind of malfunction on a Whirlpool washing machine can indicate either a minor problem or a serious defect that only a qualified technician can handle. It also happens that the error appears due to a short-term failure, and in fact there is no breakdown.

Before you undertake repairs yourself or invite a specialist, you need to make sure that this is not a normal malfunction of the washing machine. To do this, follow these steps:

If you have rebooted the unit and made sure that even with the standard parameters of the washing mode, this fault code appears on the display, you should start looking for a breakdown. Where to begin?

Prevention measures

Compliance with preventive measures helps prevent breakdowns and extend the life of Whirlpool equipment. These include:

- For washing, use only detergents that are designed for automatic processing.

- Do not send items for washing from which lint and pellets are separated.

- If power surges often occur in the house, then it is better to install a stabilizer in advance.

- Washing only at a high temperature or, conversely, only at a low temperature, contributes to a faster formation of plaque on the heating element.

- If the quality of tap water is low, it is recommended to install a filter at the entrance to the apartment to catch foreign impurities.

- It is necessary to clean the washing machine periodically.

Sma whirlpool error f08

Whirlpool washing machines are equipment for people. The creators of this household appliance have provided for virtually every nuance of using washing machines. Whirlpools differ in low price, good quality, and great functionality. These machines are quite energy efficient. Many models of various types, design solutions, are equipped with an abundance of functions, including protection from children, low noise levels, the ability to adjust the spin speed, and many others. Some models have a self-diagnosis function.

This type of equipment traditionally serves correctly, allowing owners to wash things and immediately save electricity. It is extremely unpleasant when such washing machines break down.

In the case of the Whirlpool machine, the situation is completely real and quite common - a person starts the wash, after a certain time after starting, the process suddenly stops, and the housekeeper reports error f08, displaying the code on the monitor. What does it mean? What to do? Is it possible to cope with this problem without the help of others, or in any case will you need a washing machine repair shop?

The meaning of error code f08 of the Whirlpool washing machine

Error f08 can pause washing at any step. This code indicates a discrepancy between the water temperature inside the tank and the characteristics shown on the monitor. The problem can be extremely simple, solved by a qualified technician in no time, or it can indicate a serious breakdown. There are also cases when in reality there is no breakdown at all. Before you call home professionals, make sure that this is not an ordinary failure, that the problem is not caused by your inattention:

Nothing helps? This means that the help of a specialist is required.

Problems causing error f08 of the Whirlpool washing machine

A tubular electric heater is responsible for the water temperature. Most often, error f08 is caused specifically by a breakdown of the heating element. This part requires replacement. But a malfunction of the electric heater or problems in its circuits are far from the only breakdown that can force the machine to display this code. Among the most common mistakes are the following:

All these tasks will be easy, familiar work to any specialist in our workshop. Contact us and we will solve all the problems of your washing machine. Our service center means 100% quality, low prices, professionals visiting your home and quickly completed, not bad work. Contact us and you won't regret it!

Basic codes

If your Whirlpool washing machine suddenly stops working, be sure to pay attention to the dashboard. Using LEDs, the machine will indicate the error code and significantly narrow the range of possible problems. To restore the unit, you will have to figure out what failure occurred in the system and carry out the repair yourself or with the help of a technician.

You need to count the light bulbs from left to right, and very carefully so as not to confuse the serial number of the LED.

Let's look at the main fault codes for Whirlpool washing machines and the LEDs corresponding to each error.

If repairs to the main control unit are required, it is better to contact specialists so as not to damage the equipment even more.

To clean the powder tray, remove it by pressing on the plastic tab located in the rinse aid compartment.

As you can see, the same error can indicate different failures. Therefore, it is necessary to carefully understand the problem and conduct additional diagnostics of the equipment. The explanation of the fault codes is presented in the instructions for the Whirlpool washing machine.

Let's limit the range of breakdowns

The heating element, a tubular heater, is responsible for heating the water in the washing machine tank. In most cases, the F08 designation occurs precisely when the heater fails. If this is indeed the case, you need to replace the part with a new one. But a malfunction of the heating element is not the only reason for the appearance of such an error. The code can mean something else.

To begin with, you need to “weed out” the most minor and easily fixable faults. For example, diagnose a heating element, then a pressure switch or temperature sensor, and only after checking that this is not the reason, call a technician who can make a professional decision about the condition and performance of the control module of the Whirlpool automatic machine.

Reset error

The appearance of an error message is not always a sign of a serious accident. The reason for such a situation could be, for example, a failure caused by a voltage drop. If the error appears for the first time, there is no need to panic; first, you should try to reset the error. A few simple steps will restore the device's functionality or eliminate the possibility of an accidental system failure.

To reset the error you need to do the following:

- disconnect the washing machine from the network (unplug the plug from the socket)

- keep it switched off for at least 15 minutes;

- turn it on again and try to continue washing.

If there was a failure, the machine will continue to work normally, otherwise you will have to study the instructions, figure out what this error means and look for a way to solve the problem.

Repairing malfunctions of the Whirlpool washing machine

Repairing malfunctions of the Whirlpool washing machine

The principle of repairing a Whirlpool washing machine is practically no different from other brands. At the moment, SMs are produced, with vertical and horizontal loading, in the territory of the former Soviet Union, vertical ones are more common, but now more and more machines with horizontal loading are being repaired. Here it should be noted that both types have the same weak points, first of all we are talking about the control unit, which really does not like voltage drops. As for the module, it is better not to repair this spare part yourself, but rather give it to a specialist. So, let’s put aside everything that has to do with brains and start talking about what you can do yourself. Next, I will list the error codes of Whirlpool washing machines and will immediately give a full explanation of how to repair a particular malfunction

Whirlpool washing machine errors

There are error codes that can be easily reset by pressing the Start/Pause button twice. Of course, not every error can be reset, for example, if a breakdown related to the heating element is highlighted, then in order to clear this code, you will need to either replace the heating element or change the relay

Necessary actions

If you find error E01 on the display, you should diagnose the control board. Before starting work, turn off the power to your Whirlpool washing machine. Then you can begin to remove the board from the case and inspect it. Usually, a damaged element on the board can be seen with the naked eye.

First of all, inspect the Z0103 triac; it can literally “explode” on the board due to small voltage surges.

Then you should inspect a pair of resistors in the circuit, namely R9 - 1 kOhm and R36 - 470 Ohm. If the problem is a failed triac, you will have to dismantle it and replace it, along with the resistors described above. While working, it is advisable not to rush, but at the same time clean and solder the tracks on the control board. This will improve the contact of the elements.

Replacing the sunroof locking device can help fix the problem. It is the UBL ZV-446 that often breaks down. If, when carrying out repairs yourself, you decide to simply clean the part from carbon deposits and reinstall it, a recurrence of error E01 is inevitable.

Let's check the heating element

Often error F08 appears as a result of a heater malfunction. You can check the heating element very quickly. To do this, perform the following algorithm of actions (the sequence of steps described will help owners of machines with a front-loading type; for vertical machines, the manipulations will be slightly different):

Important! The heating element is located at the bottom of the machine, under a plastic casing; only by removing the protective cover can you gain access to the contacts of the heating element.

Next, disconnect the power contacts, take a multimeter and connect its probes to the terminals of the heating element, set the resistance on the device to 200 Ohms, analyze the results. If the value on the multimeter screen remains approximately the same as it was set, then the heater is fully operational. When the number 1 appears, this indicates a break inside the part and will have to be replaced. When the device displays the number 0 (or a number very close to zero), it means that a short circuit of the heater can be diagnosed, in which case you will also have to install a new heating element.

If the heater passes the first test with a multimeter, just in case, check it for breakdowns. To do this, switch the test device to buzzer mode. You will be notified that the mode has been selected correctly by a lit light and a characteristic signal that will appear when the wires are connected. Connect one multimeter probe to the heating element terminal, and attach the second to the element body. If the device does not make any sounds, everything is fine; if a characteristic squeak is heard, there are breakdowns in the body of the part, and the heater will have to be replaced.

Let's check the thermistor

If the heating element has been fully tested and has proven that it copes with its functions perfectly, it’s time to check the thermistor. Just, it is located between the contacts of the heater. To remove the temperature sensor, perform the following manipulations:

The temperature sensor is a small metal cylinder. After the thermistor is removed from the washer body, you need to check the resistance in it using a tester.

When the temperature sensor fails, the old part should be replaced. The thermostat cannot be repaired. If the element is fully operational, we continue the diagnostics further.

We will inspect and test the pressure switch

It is easy to provide access to the water level sensor of the Whirlpool washing machine; it is located in the upper part of the unit, directly under the lid. Very rarely the pressure switch is located at the bottom. To get to the part, carefully unscrew the mounting screws and remove the upper wall of the SMA housing, after which the algorithm of actions will be as follows:

If after an external examination no defects were identified, you need to check the pressure switch with a multimeter. The device is switched to resistance measurement mode, the tester probes are connected to the sensor contacts. If the values on the screen change, it means that the contacts are actuated and the pressure switch is working. When the resistance value remains fixed, it means that the liquid level sensor has failed.

So, when you have checked the functionality of the main elements that can trigger the F08 error code, no faults have been identified, you should invite a professional to determine the root cause of the code. After all, the problem may come from the main control board, and it is not recommended to deal with it yourself.