The life of a modern housewife is made easier by household aids: washing machines, dishwashers, microwave ovens and other appliances.

However, not all issues can be resolved with their help. For example, mending clothing items requires manual labor.

The author of the article, Rozalia Khamitova, publishes tips for the home craftsman on affordable ways to repair a zipper lock with your own hands on clothes, shoes or a bag, demonstrating them with explanatory pictures and a video.

- Lock selection criteria

- Waxing

How the lock works

Lightning works on this principle:

- The latch is driven into the lightning socket;

- The pawl stretches upward to close, securely interlocking the teeth;

- If the dog goes down to open, it disengages the lock teeth.

- To prevent the zipper from spreading after closing, the eye of the dog is slightly pressed down. They simply fix it in a given position.

There are several types of lock:

- Machine. The pawl automatically fixes the position of the lock in the closed or open state. Amenable only to hand movement. Does not move up or down the zipper randomly. This dog has a special lock inside.

- Haberdashery type. It does not have a lock and can be pressed lightly in the top closed position to prevent the zipper from unfastening.

How to choose a new slider

When a zipper breaks or even falls out, some people resort to replacing the entire zipper. In this case, it is enough to change only the slider. But first, you need to buy a new one, identical to the previous one. On the back you can see a stamp that will help you determine the type of lock.

The number on the back indicates the size of the dog in millimeters. The standard size lies in the range from 3 to 10. At the same time, steel locks can go beyond these limits: be less than 3. Or vice versa, more than 10. In addition, the letter marking also has its meaning.

- A - the lock does not have a connector;

- B - one lock and a connector;

- C - two locks and a connector;

- D — two locks and two connectors;

- F — twisted zipper with one lock;

- G - no connector, lock without lock;

- H - no connector, but there are two locks;

- L - the clasp does not have a connector, but has one lock;

- X is a molded zipper without a connector and with two locks.

Another indicator of the type of runner will be its shape. So, usually a cast zipper has an oval slider, an iron zipper has a triangular slider, and a tractor zipper has a trefoil-shaped slider. Other forms other than the classic variants are extremely rare.

If the broken slider is not preserved, you can take the jacket with you to the store and show it to the seller. It will help you choose the right type of slider. Experienced professionals are able to determine the type of slider just by looking at the zipper.

Problem 1 – the zipper comes apart

One of the most common problems with zippers is that they start to separate. Not everyone knows that this difficulty, especially at first, can be solved very easily. After all, the reason that the zipper diverges is the slider (popularly this part of the zipper is often called the “dog”): it has expanded from frequent use and has ceased to press the teeth of the snake tightly against each other. How to deal with this problem?

Take pliers and squeeze firmly first one side of the slider, and then the other. The main thing here is not to overdo it, otherwise the slider will stop moving altogether. Zip up. Usually such simple repairs are enough for the zipper to start working properly.

Screwdriver

Source: Instagram (@repairshoe)

You can also use a screwdriver if the zipper comes apart. This method is mainly used in conjunction with the first one in order to better fit the zipper onto the teeth if the zipper begins to diverge. A screwdriver, like pliers, should not be used when repairing plastic zippers.

What to do

Insert the tip of the screwdriver into the slider hole at the top. Turn it so that the lock space becomes a little larger, and then take the pliers and press lightly.

Is it possible to rearrange the slider?

In principle, it is possible, but this applies to things where it is not fundamentally important which way the lock opens (handbags, cosmetic bags, etc.)

Repairing the “snake” in this case is extremely simple. Move the runner to the opposite side and sew the loose ends together to prevent the runner from slipping.

If the “dog” is completely broken, do not waste time fixing it and buy a new one at a sewing store. If you are unable to select the exact product, do the following:

- Unbend the limiter.

- Insert a slider.

- Rub the teeth of the lock with paraffin or stearin candle.

All! You can use the lock.

How to close a bag with a straw?

Place the washed products in a ziplock bag, insert a cocktail straw and zip the bag up to the straw. Using your hands, squeeze out as much air as you can, and then use the straw to remove any remaining air. The hardest thing is not to let the air back in while you close the bag completely.

Interesting materials:

Where does wild rosemary bloom? Where is the top of the shoe? Where does the Ishim River begin? Where is Samsung's calculator? Where did Alexey Chumakov participate? Where did Bogdan Khmelnitsky participate? Where do you study to become a jeweler in Samara? Where did Irina Volk study? Where did Lyudmila Gurchenko study? Where did Svetlana Loboda study?

Types

The types of zippers are determined by the functional features of the locks: the presence or absence of protection against spontaneous unfastening.

There are locks:

- auto-lock, A/L – automatic;

- pin-lock, P/L – semi-automatic;

- non-lock, N/ – haberdashery.

The use of locks depends on the type of fastener.

Auto

The A/L lock has a slider mechanism that engages the links and prevents them from moving apart, regardless of the position of the suspension. The brake is served by spring-loaded spikes located inside the runner. Disengagement occurs when a pulling force is applied to the key fob. Automatic locks are used on detachable models with large teeth.

Semi-automatic

The P/L lock has a slider with spikes located in the key fob. When the tongue is lowered, the spikes fit between the teeth and prevent the pawl from moving. To unfasten the zipper, you need to lift the puller. Semi-automatic devices are used in detachable types.

Haberdashery

Clasp with N/L lock: the slider does not have an automatic mechanism or stopper, it moves without being secured. Such sliders are installed on permanent connections.

The zipper sticks and doesn't fasten well

Trouble begins when, at the most inopportune moment, the zipper gets stuck and begins to be difficult to fasten.

The zipper can be smeared with chapstick

Usually, the first thing that comes to mind in this case is to start tugging at it and trying to move the zipper slider, but most often this leads to breakage and forced replacement of the fittings.

There is a fundamental difference in the quality of fasteners made of plastic and metal .

To restore the smooth sliding of the lock, you should use different materials that will help improve the movement of the fastener.

You should absolutely not pull, try to forcefully move the product, or make any sudden movements - all this will lead to breakage of the product.

Damage Prevention

To prevent lightning damage, you need to follow a few simple tips:

- When washing the jacket, all zippers should be zipped and the item should be turned inside out.

- When ironing clothes with zippers made of non-heat-resistant materials, avoid getting the iron into the zipper area.

- To extend the life of the lock, it must be periodically treated with special care products, such as hydrophobic lubricant. This substance provides the fastener with water-repellent and windproof protection.

- Before pulling the slider from below, you need to insert both parts into the lock all the way.

- It is sometimes necessary to treat the teeth and lock with a soft pencil lead or other substance to lubricate the surface.

- You need to fasten the zipper without haste or force; at this moment the tape should be in a taut position.

To prevent wear, all parts of the zipper should be cleaned periodically using a small brush. It is recommended to use a toothbrush, as its fibers are quite soft and small. With careful and careful handling, any item can last for many years without a single repair.

When washing, fasten all zippers and turn the item inside out.

When ironing, avoid getting the iron into the zipper area. To extend the life of the lock, periodically treat with care products.

Insert both parts of the slider into the lock until they stop. Process the teeth and lock

Fasten without haste or force

Replacing the pawl on a one-piece zipper

The permanent fastener is used in such types of clothing as trousers, skirts, and dresses. The clasp is also used in leather goods - in bags, backpacks, wallets. You can try to insert the popped pawl in the plastic zipper from above by inserting both parts of the braid with links into the slider connectors and carefully moving the slider down to the bottom stop. If this cannot be done without damaging the plastic teeth of the zipper, the pawl is installed in the same manner as for a metal fastener:

- Removing the lower limiter. Unlike the upper limiter, the lower one on quality products is made of durable and hard metal. To remove it, you need to apply force. For work, pliers and a flat-head screwdriver are used.

- The slider is positioned flat side down. Both parts of the braid with links are simultaneously inserted into the connectors from above.

- The dog carefully moves up. The teeth of the chain close and the zipper closes.

- The removed bracket of the lower limiter is installed in its old place.

Installation of the lower limiter is necessary only on the leather fastener, where it is visible. A permanent zipper in clothing, such as trousers or a skirt, is partially hidden under the seam allowance. The link chain can be fixed by fastening with several stitches of strong thread.

Similar to a regular zipper, a pawl is inserted on a secret fastener in a woman's dress or skirt. This zipper is made without a lower stop. In the lower part, the teeth are fused into a single whole; to separate them, just pull the ends of the zipper with force in different directions. The slider is inserted from below. This is possible, since the machine stitching does not reach the bottom of the chain 3 cm. After closing the links, the zipper is fixed with a needle and thread.

How the lock works

The zipper is popular for its simplicity and convenience. It is often found on clothing, shoes and bags.

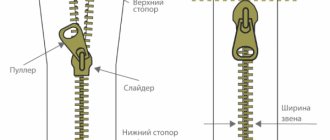

Description of design

The zipper consists of:

- two strips of fabric;

- lock (slider);

- rings;

- pendants (dog, keychain, duper);

- links;

- limiters;

- pins;

- detachable limiter with socket;

- sealing tape.

How does the lock work?

Two textile tapes with attached zipper links and a stopper on each are assembled with a lock into a common tooth engagement.

Closing work

If you pull the pawl with your fingers, the slider begins to slide along the links of the braid, connects the teeth in turn, and fixes them together: the lock closes. The limiter determines the range of movement of the pawl.

Opening work

When the lock with the suspension moves back, the links disengage and the zipper unfastens.

What type of clasp is there?

Manufacturers produce three link connection designs:

Metal zippers are the most durable in use. Tractor fasteners are highly wear-resistant, and spiral fasteners have good elasticity.

Classification of runners

Locks are made according to the type of each fastener link with different ways of its operation.

Each type of zipper uses a specific type of lock.

The slider number corresponds to the width of the links, measured in mm between the teeth when the zipper is closed. They are marked with a number on the back. The shape of the sole is determined from the underside of the lock.

Castle design

According to the method of operation, runners are divided into:

- an automatic machine whose mechanism does not allow the links to diverge regardless of the position of the pawl;

- semi-automatic, allowing unfastening only when the pawl is in a raised position. The design includes a special lock;

- haberdashery: there is no stopper and the links do not lock. This allows the zipper slider to move freely without any fastening.

Why does the lock break?

The most common cause of fastener failure is wear of the internal cavities of the slider, when the mechanism cannot connect the links and the zipper diverges.

The following are at risk from lightning:

- shoes, as they get clogged with sand and dirt;

- jackets and outerwear when they are fastened with brute force jerks;

- as well as all plastic parts exposed to sudden temperature changes.

The castle becomes unusable due to:

abrasion of the surface and increase in the gap between the side walls and links; formation of microcracks after prolonged use; mechanical failure due to careless handling, when the dog is suddenly pulled with great force; penetration of dust and dirt between the links and the lock, which begins to slow down the sliding of the slider; breakage of the pawl, which transmits the force of the hand to the zipper lock.

Using a screwdriver

This advice is effective if we are dealing with a metal runner. If your zipper has come apart and the slider is hanging on one of its halves, take a flat-tip screwdriver and insert it into the upper groove of the slider - the one that grooves the lock. You perform this action in order to slightly expand the slider flaps. After the required bosom has opened a little, insert the free half of the zipper into it, and secure the result with pliers.

Do not press the slider too hard with pliers, even if it is made of metal, it may still break.

After all the manipulations, check the slider in action, it should work like new.

It's hard to imagine clothing without the favorite fastener - the zipper. It has many positive characteristics: reliability, compactness, beautiful appearance and much more. It is used in the manufacture of jackets, coats, jeans, skirts, dresses, bags, wallets, shoes and other necessary things. If the zipper breaks, how to fix it yourself and quickly is the first thought that comes to mind.

Sometimes a fastener can cause a lot of inconvenience, since it has one peculiarity - it breaks when you least expect it. And then the search for information that will help correct the situation begins. The zipper broke: how to fix it? First of all, you need to understand the causes of the breakdown. In some cases, it fails because the maximum period of use has been exhausted. Sometimes a brand new zipper just breaks. In this case, it is unlikely to be repaired.

Repair features

The zipper is the most vulnerable part in any item. It is subjected to constant mechanical stress, which leads to rapid wear. Replacing a zipper requires some experience. In some cases, for example, in shoes, this can only be done by a professional using special equipment.

Jacket

You can repair a jacket yourself if you have a sewing machine. First you need to remove the old zipper. At the same time, the finishing and connecting seams are opened. On a leather jacket, the tape is glued on: it needs to be torn off. In a fabric jacket, a new fastener is inserted in place of the broken one and basted to the lining. Fasten the zipper and check its operation. The seam is sewn using a machine. Baste the upper part and sew along the old seam.

For a leather jacket, the new zipper is first glued on both sides. After drying, determine whether the zipper is installed correctly. The zipper is sewn in with one seam, covering 3 layers: trim, leather, backing. The threads used are strong, elastic (not fishing line).

Bag

If a leather bag does not fasten, it is better to have it repaired. Inexpensive bags can be repaired yourself. They are equipped with twisted zippers, which are easy to replace.

Backpack

To replace a faulty zipper, it is removed. The new fastener is straightened open and sewn on. If the zipper comes apart on one side, then trim the fabric where the lower part of the braid is sewn. Insert the tape into the runner and check the engagement of the teeth.

When the zipper diverges again, the slider is removed and its edges are pressed using pliers. Tapes with teeth are inserted into it. Secure the lower part of the zipper with threads and sew it in following the traces of the old stitch.

Jeans

Jeans have a metal zipper on the fly. Sewing a new fastener yourself can ruin the item. The repair consists of adjusting the sides of the slider to eliminate the discrepancy of the teeth.

Common causes of breakdowns

There are a large number of reasons why the zipper on a jacket does not fasten. Such damage occurs due to poor quality of the product, prolonged wear and the use of a fastener. Other reasons that can lead to the lock on a jacket coming apart include:

- Improper storage of products with zippers - under the influence of elevated temperatures or pressure, the fastener may become deformed, as a result of which it ceases to fulfill its intended purpose.

- Unfavorable weather conditions (rain or snow), which wear out the snake even more, especially if it is used during rainfall.

- Careless use of a snake. This causes the problem of the slider loosening, which subsequently does not hold the teeth of the tape and does not fix them. Such cases occur during a rush and strong twitching of the snake.

- Active use of the lock, which leads to rapid wear.

- Poor quality of product. Often, failure occurs due to fraying of one of the parts of the double tape, which results in difficulties in merging the two components of the snake, and the zipper diverges after fastening.

To understand how to fix a zipper that is coming apart on a jacket, you need to accurately determine the location of the damage. Many things with snakes are purchased for several seasons. The clasp lasts on average 1-1.5 years. When purchasing a product, it should be carefully inspected. It is better to take clothes with glued tape, in this case the fabric will not come apart.

Improper storage Adverse weather conditions

Careless use of a snake

Active use of the lock Poor quality of the product

Secrets of zipper care and breakage prevention

Always try to unfasten and fasten the lock slowly and carefully

It is especially important to explain to children that lightning does not tolerate sudden jerks or the use of brute force. Align the edges of the clasp before fastening

On some products, the zipper may bristle - it is advisable to try to straighten it and tighten it. If the fastener has become very tight, it makes sense to lubricate it. A bar of soap or a wax candle is suitable for this - just rub the teeth on each side and enjoy the ease of unfastening.

Zippers on shoes should be cleaned regularly using a small brush. Fasteners of this type are especially susceptible to dirt and sand. Zippers on clothes have completely different “weaknesses”. Before washing, they must be fastened and the product turned inside out. When ironing, try not to touch the clasp with the iron. By following these simple rules, you will most likely never run into problems. But if the zipper on your bag does come apart, you now know how to fix it.

Solving the lightning problem.

Today it is difficult to imagine how we managed before without such a convenient and practical fastener - a zipper, which has become an integral part of many items in our wardrobe. Clothes, bags, shoes - this is not the only area of application for such a useful invention. But what to do if it breaks? We will try to understand this further.

Lightning came off

If, due to careless fastening, the zipper has partially come off the jacket, it simply needs to be sewn on by hand with thick threads. If the zipper comes off over a large gap, it would be more careful to sew it on with a machine

Sew on a zipper

Tips for moms:

Some mothers recommend sewing on a new zipper without removing the broken one. In this case, you need to sew the new lock as close as possible to the old one. The option is not the best, but it will work for street clothes for nimble boys.

How to unfasten a zipper if it comes apart, what to do to prevent the zipper from coming apart: tips

Sometimes on a zipper that has come apart, the slider gets stuck at the top or in the middle. What can be done in this case?

The technology depends on the type of zipper.

Detachable (used on sweaters, jackets or other outerwear):

- insert the lower ends of the fastener into the square clamp

- hold the dog by its base, not by its decorative keychain

- pressing the slider to the links, move it down smoothly and slowly

- Use your other hand to constantly hold the clasp

- Having reached the latch, carefully engage it with the slider

- unzip

One-piece (sewn into jeans, skirts, trousers, bags, wallets):

- release the stoppers at the top of the fastener

- smoothly slide the slider to the edge of the tape

- try not to get the fabric between the teeth and the dog

- remove the carriage from the zipper

Now check if the fastener can be repaired. For this:

- manually connect the lower ends at the clasp

- with your other hand, grab the base of the slider

- holding the lower end, slowly move the pawl up the zipper

- if during this action the links of the zipper do not connect, it must be replaced

In the case when adhesion between the fastener links does occur, there is a chance to repair the zipper yourself. It happens that lightning diverges from above. This problem especially often occurs with jeans or skirts.

In emergency cases, this method can help:

- insert an elastic band or wire ring into the dog

- fasten the zipper

- place the elastic band (ring) on the button

- thread the button through the loop

To ensure that the zipper serves you for a long time and does not break, use it correctly:

- do not pull the pawl with all your might and do not pull it back when fastening/unfastening

- Before fastening the zipper, straighten the sides of the product so that there are no stretched areas

- in cases where the lock is too tight, lubricate it with a suitable product or rub the teeth with a graphite pencil lead

- avoid putting too much pressure on the fastener (buy clothes that are not too tight, don’t carry a lot of things in your bag)

- Periodically clean the clasp from dirt using a brush

- Always zip up the item before washing and turn it inside out

- fold things in such a way that the zipper does not bend

- When ironing clothes, avoid touching the fastener with a hot iron

How to repair a zipper on a jacket at the base?

The stopper with the pin has fallen off, so the lock diverges at the bottom

To do this, you need to make a through hole in the fabric, put a pin on the glue and secure it. Instead of a pin, you can use a cocktail tube: flatten it several times and insert a piece in place of the pin, securing it with glue.

Let's fix it!

The slider tongue is broken

It is enough to replace it with improvised means: a pin, a paper clip or any metal ring. They are inserted into the hole and used like a regular slider. This, of course, does not look very aesthetically pleasing, but it will help solve the problem with the fastener for a while.

Quick tongue replacement

The slider itself is broken

Then it must be replaced with a new one. It is inexpensive and sold in any sewing store. To install the slider you will need a thick needle or scissors. You need to slightly unclench it on one side, install it on the zipper and squeeze it.

Next, you can watch the video How to replace the slider yourself at home

Different variants

How to quickly fix a plastic zipper if it comes apart or the slider has fallen off?

Manufacturers most often use plastic zippers for their products, which are sometimes called “tractor zippers.” It is not as durable as metal, but has, in comparison, a number of advantages:

- doesn't cling

- easier to fasten

- weighs less

- has a variety of colors

However, the disadvantages of a plastic fastener are that it breaks faster and the slider “flies off” more often.

When the plastic zipper just starts to come apart, do the following:

- unfasten the clasp

- treat the cloves with a cotton swab dipped in an alcoholic rosin solution

- let dry for several hours

If this method does not help correct the situation, then the slider is most likely damaged. It is unlikely that it will be possible to press it with pliers, since the plastic may simply burst. Therefore, the best solution is to replace the “dog”. This is done in the same way as in the case of metal zipper, taking into account some points:

- Simply glue the fasteners that are removed from the clasp to replace the pawl in their original place

- in cases where this cannot be done, make several stitches in place of the stops with threads of a matching color, which will hold the slider

- If the base of the permanent zipper is damaged, coat the area with clear varnish and let it dry completely.

- in the case when several teeth on the nylon “snake” have fallen out or are severely damaged, sew this area with fishing line, twisting the turns

- It is usually not possible to insert a “dog” into thin nylon zippers, since it is too small. Therefore, it is better to take clothes with such locks to a studio, where they can easily replace the fastener with a new one.

In emergency cases, when there is no possibility of purchasing a new slider, and there is nothing to replace the item on which the fastener has come apart, you can try the following:

- use a lighter to heat the slider

- under the influence of heat, its walls will become a little softer

- squeeze the edges of the slider tightly

However, it must be said that this method is not very reliable due to the risk of damaging the fabric of the item or the zipper itself.

New teeth

This is more painstaking work, unlike the previous ones. If you don’t want to take an item for repair, then you can practice restoring things yourself. For example, when several teeth fell out of the zipper on your favorite jeans, you can rearrange the missing parts from another zipper or buy them at a sewing store.

What to do

Move the new teeth into place using tweezers and secure with pliers.

Don't miss Don't miss How to replace a boring French manicure: 7 original ideas

How to extend the life of a zipper

In order for the clasp with a lock to last as long as possible, it is enough to follow simple rules:

- use the dog carefully, do not subject it to sudden loads;

- do not bend the zipper during storage;

- if the metal fastener diverges, then try to adjust the movement of its lock with pliers or a hammer;

- do not allow the fastener made of plastic to touch when ironing clothes with a hot iron;

- fasten the lock for the period of washing clothes until it comes into contact with the limiter;

- Use wax or pencil lead as a preventative lubricant in the early stages of wear of the fastener lock.

Source: arenahots.ru

How to improve zipper performance

There are several simple ways to treat surfaces using lubrication:

- wax;

- pencil lead.

Waxing

You can rub the cloves on both sides with a regular paraffin candle or beeswax. The zipper can be closed or open.

The paraffin will fill the voids between the teeth. The runner will slide more freely.

Lubrication with pencil lead

It is recommended to follow the color scheme and carefully handle the zipper teeth with a stylus. The pencil should be soft, a 3M or 4M brand intended for drawing is best.

Lubricating the zipper with wax or pencil lead makes it easier to slide, protects from external influences and increases the life of the slider. However, graphite can penetrate clothing and contaminate it.

Types of lightning

Fasteners are classified according to the method of release: complete or partial. The use of one type or another depends on the functional purpose of the thing.

Unilateral

Detachable models are one-sided types. When unfastened, the clasp splits into two sides, the slider remains on one of the halves. The design feature of detachable zippers is the presence of a pin and a detachable limiter with a socket. The connection occurs using a pin, which passes through the holes of the slider and is secured in the stopper. When separated, the pin remains on one half of the braid, the slider on the other. Single-connector types may have 1 or 2 locks. Two-way zippers have a more massive stopper and a longer pin. Such fasteners are used on outerwear and sportswear.

Double sided

On double-sided fasteners, the pawl always connects both halves: in the fastened and unfastened position, which is typical for one-piece models with one or two locks. Such zippers are used on shoes, bags, clothes (trousers, skirts, dresses). The fasteners have free edges of the tape. At the bottom - the end point of unfastening - they are connected by one common stop. In the upper part - the end point of fastening - two (for each half of the zipper).

This type includes a two-way, detachable zipper with two locks, in which the unfastening occurs not to the edges, but to the middle or from the middle to the edges. Two sliders act as a limiter in the central part of the fastener.

The main problems with zippers on clothes. How will the studio masters be useful?

Despite the reliability and practicality of modern zippers, they periodically fail, forcing owners to rush to look for the nearest repair shop. What might you encounter?

- The zippers come off - master seamstresses will quietly sew the runaway fastener back into place.

- The zippers come apart and jam - replacing the zipper lock can help. This is a quick procedure that requires a minimum of your time.

- Complete breakdown of the zipper - a complete replacement of the fastener is necessary, which is often required for down jackets or jackets. Tailors will carefully rip off the old clasp, find a similar new one and beautifully sew it into the product.

The cost of replacing a zipper depends on the complexity of the job and the length of the product. Simply hemming the torn fabric is easier than replacing the entire fastener.

How to fix an insertion pin

The most effective way to fix a zipper on a jacket is to take the garment to a repair shop. Professional craftsmen will replace the mechanism and the product will not lose its original appearance. This will require time and money to pay for the work.

If you need the jacket urgently, you can fix the zipper yourself. To do this you will need a cocktail tube and glue.

Step-by-step instructions for fixing the lock:

- Inspect the place where the pin is attached at the base. If the sealing tape has come off and the fabric is frayed, then treat the area with glue or nail polish. The frayed edges are carefully trimmed with scissors.

- A piece 1 cm long is cut from a cocktail tube. The ring is cut lengthwise and unfolded and bent in half.

- The end of the zipper, where the insertion pin used to be, is coated with glue on both sides. A piece of plastic tube is glued to the fabric and pressed with a weight until the glue dries.

- After drying, cut off the remains.

- The place where the plastic pin is glued is stitched. This will provide additional reliability and extend the service life.

The result is a dense pin that easily fits into the slot of the slider and the detachable stop. If the color of the plastic is very different from the background of the jacket, it is painted with nail polish.

Important! Self-repair is a temporary measure. Plastic quickly becomes unusable and stands out strongly

After the end of the season, the jacket should be taken to the studio and undergo a full repair.

You can see the repair process in detail in the video:

If the bottom is frayed: repairing the zipper using a cocktail straw and other options

If the tip of the lock is frayed, the latch will constantly pop out. Then repairing our zipper using a regular plastic cocktail straw will help us. The frayed edge must be cut off, the edges must be melted over the fire of a candle or lighter and flattened. Cut a piece of straw about 1 cm long and place it in place of the latch. Heat and flatten with pliers.

Video from China, but still everything is clear

If you need to repair the edge, but there is no straw at hand, you can apply any instant glue to the place of the fastener, wait until it dries, and use a nail file or file to give it the desired shape.

Problem 2 – replacing the zipper slider

However, sometimes even after such a procedure the slider does not cope with its duties and does not clamp the teeth. In this case, it becomes necessary to replace it. This can be done in several ways.

Method 1

At the top of the zipper there is often a stopper, thanks to which the slider does not move out of it when fastened. However, when you need to install a new slider, this latch becomes an obstacle. How to get rid of it? Take a screwdriver or any flat object and lightly pry open the stopper. You can use wire cutters. Remove it from the zipper. After installing the new slider, place the retainer in place and firmly pinch it with pliers.

Method 2

There are also limiters on the plastic zipper. However, unlike metal ones, they are disposable: once you take them out, you can’t put them back. How to replace the slider in such a situation. Take pliers or scissors and simply remove the restrictor from the clothing. After replacing the slider, you need to make sure that this place protrudes above the teeth so that it cannot slip off. This can be done using thread. Take a thread and a needle and make a few stitches in the place where the latch was. You can also install a metal stop if you have some left over from another item.

Method 3

Sometimes there is no limiter on the zipper, and the slider does not move off the fastener due to the fact that its ends are sewn into the product. How to be in this case? There is only one way out here. Take a seam ripper or small scissors and rip the edge of the garment. Remove the slider from the zipper and replace it with a new one. Then arm yourself with a needle and thread of a suitable color and sew up the ripped part.

Replacing the slider at home

To correctly replace the old slider with a new one if the zipper comes apart, you must follow this procedure:

- Remove the broken slider. To do this, you need to use a needle or awl, with which you disconnect the metal retainer.

- On the new dog, push the edges a little further. It is important not to use too much force to avoid breaking the clasp.

- Install a new zipper pawl. After this, lightly pinch the attached edge using pliers.

Stainless steel and hard plastic are the best materials for zippers; they tolerate various weather and temperature conditions well, and are also resistant to medium loads.

Remove the broken slider. On the new pawl, push the edges apart. Install the new pawl on the zipper.

The zipper doesn't fasten well

This is not such a rare occurrence. The “dog” slips through the lock with difficulty, and additional difficulties arise with fastening and unfastening. How to fix the lock on the jacket in this case?

There are several ways to debug the zipper:

- Lubricate the lock with lard along the entire length. This repair method is suitable for leather products. If the item is made of textiles, greasy stains may appear on it.

- Candle wax. Once lubricated with wax, the fastener begins to work normally.

- Soft pencil lead. Using graphite to lubricate the snake, as practice shows, is the most effective.

Structure of lightning

To understand how to repair a lock, it is important to understand its structure.

A whole zipper consists of the following parts:

- Two strips of durable fabric with teeth on one side;

- Dog Runner;

- Limiter (aka clamp);

- Sealing tape at the bottom.

Video

Surely many of you have had a zipper break. The zipper is a popular fastener, especially the detachable zipper, which is convenient, but unfortunately, sometimes it breaks. And it is the part that breaks that is located below and that is inserted into the mating part, where it is fixed. What to do if you don’t want to change the lock, yes, sometimes it’s not so easy (it can be sewn very awkwardly), but you want to wear a jacket with a zipper. This happens especially often with children's jackets and sweaters. The children pull the zipper, they are in a hurry, and they tear the mechanism. In order not to throw away almost new children's clothes, parents simply sew up the bottom part of the lock and have to put the jacket on first over the head, like a sweater, and only then zip it up. But this is not only inconvenient, but also not very beautiful... You can’t send a child to school in such a jacket, especially when he is already a teenager.

So, you don't want to sew up the lock at the base and are unwilling (or unable) to replace it. Well... Then let's fix it.

First, we need a piece of iron from which we will make the part we need. We also need superglue and a paper clip. Superglue is one that hardens very quickly and becomes “like glass,” very hard (based on cyacrolate, sold in small tubes of 1-2 grams).

So, we remove all excess, after soaking the fabric with superglue. It will set quickly and add rigidity. Carefully cut with pliers. (photo 1).

Now comes the main part. We cut it to size from a piece of stainless steel or tinned tin (you can take it from a condensed milk can) and roll it up as shown in photo 2.

It should fit well into the part of the lock that moves and be well fixed in the part that is located below (photo 3). Next we manage to fasten the lock (photo 4). This can be done by hand connecting each clove in sequence. Surely, everyone did this when they were trying to understand how this thing works or when the lightning “spread” in the middle.

After this, we place our piece of iron on the inside of the lock and place it on superglue (photos 5 and 6). We try to unfasten it. If you did everything well, then the lock should come unfastened, although at first, until the piece of hardware gets used, this can be done with some effort. Take your time, because... the glue may not have time to set completely. So, you unfastened the lock. Everything works, but it's not enough.

Now we need to strengthen our structure. We drill 2 small holes and insert a bracket made from a regular paper clip (photo 7, 8,).

That's all now (photo 9, 10).

We finally check the operation of our lightning. For a better look, you can touch up the sizing areas with a permanent marker. For good performance, I recommend rubbing the lock with paraffin or stearin (a regular candle) or just soap.

Some useful tips related to zippers

If the zipper lock is a little tight, rub it with a stearin candle. This advice is especially effective for metal zippers. A soft pencil lead will also help. It is enough to pass it along the zipper several times.

If the zipper often spontaneously diverges in the middle, lightly tap the lock (its edges, not the bracket to which the tongue is attached) with a small hammer.

Tapping the zipper itself, if it is metal, will also help.

The lock will become tighter, but the zipper will stop moving apart.

If the tab on the zipper comes off, it can be replaced with a regular paper clip.

If the zipper on your trousers tends to undo itself, thread a small key ring through the zipper tab and place it over the button of your trouser waistband. Such a ring can also be made from a paper clip.

Zippers on shoes suffer greatly from dampness, wet and salty snow, and slush. Which dramatically reduces their service life. Rub a piece of unsalted lard over them or use a special hydrophobic lubricant more often. And the lightning will be protected from dampness. Such lubrication will also improve its performance.

So the zipper is stuck and won't go down, and you're trapped by your item because you have to unzip it to get it off.

Take a regular pencil with a graphite tip and rub it over the teeth of the zipper. This should help. If not, you need to increase the glide, such as rubbing the teeth with soap, lip balm or detergent that reduces friction.

Using a Q-tip, apply lubricant to the zipper and teeth. Then pull the fastener down and repeat the lubrication procedure again. Continue until the clasp is completely undone.

tube

This method is suitable when the lower stop on the zipper of a jacket or sweatshirt is stuck or comes off. That part that we insert into the fastener so that we can then fasten the zipper.

What to do

If the bottom stop comes off, cut off all the old threads or pieces of fabric around the gap so that they are not in the way. Then apply clear varnish to the area to be repaired. While the varnish is drying, take a cocktail tube and cut 1-2 centimeters from it. Then cut it lengthwise so that the tube turns into a plate. The next step is to apply glue to the mounting location. On top of it you will need to place a piece of plastic folded in half.

Place the treated area of the item under a press and leave to dry for a day. Afterwards, cut off all excess and sew for safety.

How to fix a zipper

Of course, there are different situations. Sometimes a zipper simply crumbles into pieces from long use, and sometimes a completely new zipper breaks like rags. Then there can be no talk of any repairs. But, most often, the zipper can be quickly repaired. So, let's look at the most typical cases.

Lightning begins to disperse

If this happens, then there is no need to rush to change it. First, you should try to lightly tap it from the inside and outside with a hammer, and you will have to walk along the entire length three times

Then you will need to reduce the gaps between the top and bottom of the slider, for which you will need to carefully squeeze it with ordinary pliers. But such resuscitation can only be carried out once; the castle will not withstand any more and will completely fall apart.

Therefore, if you managed to save your zipper once, then try to prepare a spare slider - just in case of a fire.

If the zipper comes apart, you can try to fix it at home. Below are step-by-step photo instructions

If the lightning diverges periodically

If the zipper diverges periodically, and this is not the first time, then you will have to change the slider (“pawl”). To remove the old slider, you need to remove the stopper (small plate) located at the bottom or top of the zipper.

Teeth fell out

When several teeth have fallen out of a nylon zipper, you can also try to restore them using a bandage: the damaged area is stitched with fishing line, turn by turn.

If the zipper comes off the base

If the clasp is suggested by an online resource. And a zipper torn from the base (fabric) can be sewn on using a machine needle. This method is especially convenient for repair work in the most difficult to reach areas, for example, in boots, since the puncture is carried out only in one direction.

It is better to sew a torn zipper using a machine

If you need to repair a metal zipper

If it is not a nylon, but a metal zipper that comes apart, then it must also be carefully forged on both sides, but with heavier blows of the hammer, and then reduce the gap between the lower and upper halves of the lock.

If the plastic zipper breaks

A plastic zipper that is starting to come apart on a shoe can be repaired. Its performance will be restored if you unfasten the lock and moisten its teeth with an alcohol solution of rosin (flux used for soldering). Then you need to let the zipper dry for several hours. This way the fastener will work more reliably, but over time this operation will have to be repeated.

A plastic zipper requires more careful handling than a metal one

Slider repair methods

If the zipper starts to come apart, you can try to repair the lock yourself.

There are two simple methods:

- tighten the increased gap with pliers;

- bring the edges together with a hammer blow.

Working with pliers

To do this, you need to close the zipper and press the side parts of the slider at the ends on the outer and inner sides of the lock.

The gap between the teeth will come closer: the zipper will stop diverging. You must work carefully so as not to pinch or break the slider.

The space to tighten the sides of the lock is limited. Therefore, it is more convenient to work with a tool with long and narrow sponges - platypuses.

Oleg Ars talks about this method in more detail in his video.

Hammer repair

You can correct defects in the lock by lightly tapping it with a small hammer on its edges, avoiding hitting the central part.

It is necessary to provide a rigid support from below: you can place a flat solid object or plate. To avoid accidentally hitting the middle part of the lock, it is recommended to additionally use the upper stop. This method is better suited for metal zippers.

Repairing the runner using a small hand vice is based on the same principle.

However, all these methods require great care and precision. It is quite easy to exceed the mechanical force and break the lock: it will need to be replaced.

What will you need for replacement?

To install a new fastener, you need to select a similar one using auxiliary tools and materials.

New slider

When selecting a zipper, pay attention to the dog. The functionality of the zipper depends on its qualities. If the fastener is changed on shoes, then the slider should have a thicker base. For outerwear, backpacks, and tents, a durable lock made of metal is required. A convenient pull tab is necessary for using the zipper with gloves and for children's things. The broken slider is replaced with a similar one. The need for replacement arises when cracks appear in the sole or when the puller is irreparably damaged.

For each type of zipper, a different slider is selected, since they have design features of the sole.

The shape of the sole of the sliders for metal teeth resembles the letter “P” at the bottom and top. Spiral pawls have a straight bottom sole. Shoe locks have a reinforced sole, 3 millimeters thick. Tractor locks are structurally similar to metal locks. Runners are made of metal or plastic. Plastic ones are used for narrow synthetic fasteners. Metal ones are used for all types of zippers.

See also

Causes of air conditioner malfunctions and how to fix them yourself

Small scissors, blade

Short scissors and a razor blade are needed to carefully trim the seams connecting the braid to the lining and to detach the zipper that has become unusable.

Needle and thread

A needle of medium thickness and thread in the color of the braid are required for sewing in a fastener, fixing the stopper, and strengthening the connecting seams with the lining.

Pliers, pliers or side cutters

Tools are used to adjust the edges of the zipper after sewing the zipper in if it is too loose. With their help, the side, rear and entrance gaps of the runner are reduced.

Knife (screwdriver)

A knife or screwdriver will be useful to loosen the edges of the slider if they are too tight, and also to bend the stops.

Glue Moment

Quick-drying glue will be needed to strengthen the tape at the junction with the stopper.

How to extend the performance of the lock on a jacket?

To prevent unfortunate situations with a zipper breakdown from occurring at the most inopportune moment, we recommend taking preventive measures. They prolong the performance and preserve the aesthetic appearance of the lock.

The first thing you can do to the zipper of a new jacket is to lubricate it. You can lubricate the zipper on your jacket with candle wax, soap, oil or greasy cream. Do not apply too much substance to avoid staining the clothing material.

Another necessary action is to close the zipper when washing.

You should also protect the lock from strong and constant wetness to prevent rust from forming.

As it turns out, it’s not difficult to fix a zipper when the tongue of the dog has come off or it’s completely broken, the teeth or the stopper have fallen off. Trouble can arise in the most unexpected places, and a quick fix will come in handy. Step-by-step instructions on how to repair a zipper on a jacket with your own hands explain what to do in case of various types of lock failures.

Please rate how useful this article was to you! ( 1 ratings, average: 5.00 out of 5)

Yandex recommends - the best articles on the site

You may also be interested in

- My jacket is torn, what should I do? How to sew beautifully...

- The synthetic padding in my jacket has gone astray, what should I do? How to whip...

- Instructions: how to remove a greasy stain on a jacket?

- Leather jacket torn? How to repair? How…

- My jacket is dirty, what should I do? How to clean a jacket...

- Top 20 products to remove burnt marks from your iron...

- Instructions: how to properly wash a leather jacket in...

- Instructions: how to remove the smell of sweat from clothes under...

- 11 Effective Ways to Soften a Leather Jacket in...

- The item shrank after washing, how to return it to its original size -...

- Life hack: how to peel a pomegranate without much effort

- How to iron a leather jacket at home...

Why does the zipper come apart: reasons

The zipper is called differently:

- "snake"

- zipper

- clasp

It is one of the types of fasteners that is designed to quickly connect parts of clothing. Modern designers are developing new versions of zippers with improved fasteners to prevent possible breakdowns. However, unfortunately, a model that would never break has not yet been created. And over time, most of the “snakes” begin to diverge.

In order to understand the reasons for the trouble that happened, you need to understand how such a fastener works and what the principle of its operation is. “Snake” consists of two textile tapes with links (teeth) attached to them. These links are staggered and can be:

- plastic

- metal

- nylon (flexible, on a thin fabric base with spiral staples)

The teeth are connected to each other using a lock, which goes by different names:

- slider

- "dog"

- slider

- carriage

The operating principle of this fastener is as follows:

- the slider slides along the tape, connecting the links together like a puzzle

- each link is fixed by two links on the opposite side

Possible reasons why the teeth do not connect on a zipper:

- The slider is loosened and does not fit tightly to the tape

- the shape of one of the elements is broken

- the slider has broken down

- the teeth on the clasp are broken or deformed

- there is thread or fabric stuck in the lock

- dirt has accumulated between the links (this problem often happens with shoes)

How to open a zipper without a pawl?

To repair such a “zipper”, you need to unzip it, moisten its teeth with a solution of rosin in alcohol and leave it for two hours so that it dries. A metal zipper that diverges can be repaired by lightly hitting the entire length of the zipper on the outside and inside with a hammer.

Interesting materials:

How to stretch an image vertically and horizontally in GR Paint? How to enable first person sight in GTA 5? How to find your profile on Instagram? How to cut out an image in canvas? How to block a contact in mail ru? How to send a private message in Minecraft? How to get 64 at once in Minecraft? How to heat tea in the microwave? How to go down in Minecraft? How to withdraw Cashback in Monobank?

How to replace. Sequencing

Replacing the zipper in stages:

- use scissors and a blade to trim the seams;

- pull out the clasp;

- remove the remaining threads;

- insert a zipper;

- attach the braid to the lining;

- test the operation of the lock;

- sew by hand or by machine.

Glue will be needed to secure the bottom of the detachable zipper.

If the detachable zipper stopper with the socket for the pin has come off from the fastener, to put it in place, you must:

- drill a through hole;

- put it in the same place with superglue;

- rivet

As a result of the repair, the functions of the limiter will be restored. If the zipper teeth are broken. Instead of ripping out the zipper, an alternative option is to stitch a new zipper underneath.

What types of link fasteners are there?

Few people probably know, but zipper elements also have “serious” scientific names. So, the fastener itself is called a zipper, a zipper, or a snake. The components are elements such as a puller (tongue), slider (the part that is designed to connect the links, also commonly called a pawl or slider), links (teeth), upper and lower stops (locking elements).

If you look closely, the snakes differ from each other in appearance.

Tractor lightning - based on the name, resembles a tractor caterpillar. The free-standing teeth on the base are rounded and, when fastened, resemble a wave.

At first glance, a twisted zipper has teeth that are spaced more often. The design is a spiral attached to a braid. It is positioned in such a way that the spiral forms protrusions that will cling to the opposite ones.

Depending on the material used, zippers can be made of plastic or metal.

This information will be useful when you need to repair the zipper on the jacket at the base, or if the slider or tooth breaks.

What do the numbers mean?

The numerical designations refer to the size of the teeth: they show the width in millimeters when the zipper is closed. Markings are applied to the slider from the inside. The shape of the upper part of the tongue depends on the type of links.

Metal teeth come in 3, 5, 8, 10 millimeters, the top of the slider has a triangular shape. Molded plastic teeth (tractor) - 3, 5.7, 8, 10 millimeters, oval or trefoil-shaped runner. Twisted plastic links (spiral) - 2, 3, 4, 5, 6, 7, 9, 10 millimeters, the slider resembles an oval. The longer the teeth, the stronger the connection against tearing and stretching.

Metal fasteners

The teeth of a metal zipper are made of flat brass or nickel wire. The shape of the links is asymmetrical: on one side there is a protrusion, on the other there is a recess. The connection with the braid is two-way. The quality of the clutch is high, but due to the misalignment of the teeth, the slider may “stick.”

Tractor zippers

The fastener consists of wide plastic teeth attached to a thick band on one side. The shape of the links resembles a caterpillar track. The advantage of such a zipper is the wear resistance of the links. But in terms of the fastening method, it is inferior in strength to metal and twisted fasteners.

Twisted clasps

A zipper is made from a fishing line rolled into a spiral. The fiber is wound or sewn onto the braid. The adhesion is formed by the fiber protrusions on both sides.

What to do if lightning diverges

First of all, it is necessary to determine the reason why the teeth do not hold the clutch. Depending on the defect, repairs are made.

The castle fell apart

The cause of weak adhesion is wear on the edges of the runner. Using pliers or pliers, squeeze the slider from the front and sides. Metal pawls are repairable. Significant effort is not required so as not to deform the mechanism. The manipulation is carried out with the zipper unfastened.

Broken dog

The slider becomes unusable if it has a crack in the sole; wear of the edges and grooves when compressed does not give the desired effect when compressed. The runner is selected in accordance with the size and type of tooth and the purpose of the item. For example, for a detachable “tractor” zipper on outerwear, you will need a metal slider No. 7; for a spiral zipper on shoes - reinforced plastic lock No. 6, 7.

To replace the dog you need:

- use an awl/screwdriver/knife to remove the holders at the bottom;

- pull out the slider;

- put a new runner on the ends of the braid;

- advance and fasten to the length of the pawl;

- put the holders in place.

Upon completion of the repair, check how the lock works.

The tongue fell off

You will need to install a new slider if the connection to the slider breaks along with the tongue. But if the suspension breaks off, but the ring remains intact, it is enough to change only the tongue: insert a homemade one or remove it from an old zipper.

Lightning came off

The torn braid is sewn back to its original place by hand.

Fracture of the base

The zipper will diverge at the bottom if the split zipper stopper with the pin socket has come off. To put it in place, you need to:

- drill a through hole;

- put it in the same place with superglue;

- rivet

See also

How to properly glue sound insulation in a car with your own hands, step-by-step instructions

If the plastic stoppers of the one-piece zipper break, the failed parts must be removed. Impregnate the braid with Moment glue, put the stops back and keep under pressure until dry. The second reason for the zipper to fail at the base is wear and tear of the fabric. To restore it, use manicure varnish. The braid is given the desired shape and soaked twice with nail polish. Rubber glue and Moment can be used as impregnation.

The lock tooth is broken

Dropped links disrupt the fixation of nearby teeth, which leads to the divergence of the zipper.

The method of restoration depends on the type of link:

- Spiral breakage. To restore it, you will need the same section of fishing line. A piece of fishing line is pulled several times at the defect site. The diameter of the winding must match the diameter of the remaining links. You need to make a small knot on the inside of the braid and seal it with the fire of a match or lighter.

- Loss of a metal tooth. Repair the zipper if similar teeth are found. The dimensions and shape must be identical. The links are separated from the old fastener, placed in empty places and clamped with pliers. Place the zipper on a flat place and tap the links with a hammer. Check the fastening and operation of the slider.

Stuck

By all indications, the whole zipper can be tightly fastened and unfastened, which often happens with new products. To facilitate the sliding of the runner along the toothed belt, various lubricants are used.

Liquid soap or shampoo

The plastic teeth are carefully wiped with a sponge soaked in detergent.

Vegetable oil

A few drops of vegetable oil placed in the slider will reduce friction when moving along the metal teeth.

Special graphite grease

Graphite lubricant is applied to the metal teeth so that the slider can even out casting defects.

Prewash

A zipper on a cotton braid must be washed before installation to allow the material to shrink.