Traditional oven cleaning: what is it?

Traditionally, detergent and a sponge are used to clean the oven. The traditional cleaning system is called the usual, “grandmother’s” methods. Sponges, special powders and liquids, as well as folk remedies for removing carbon deposits are used here. The disadvantages of this method are obvious:

- time-consuming and labor-intensive process;

- the need to clean trays and grates separately;

- risk of damage to surfaces.

The only advantages include energy savings and low cost of stoves that are not equipped with a self-cleaning system.

Cleaning options

Advanced technologies do not stand still, forcing stove developers to find new solutions that make oven care easier. Recently, models have appeared on sale in which the door can be removed. This greatly simplifies regular cleaning of the oven and makes it possible to treat the most difficult to reach places.

Many housewives appreciate the oven, which is equipped with a special trolley that allows you to easily pull out the work surface. If you use this function during frying, you can easily check the readiness of the dish. Cleaning is also simplified: the removed panel is washed separately from the stove.

Some ovens are coated with a special enamel that contains oxidation catalysts, which lead to the breakdown of fats when heated.

The pyrolytic cleaning function is considered the most expensive and high-quality, but it is installed only on electric stoves.

Easy-clean oven enamel: what is it?

The special coating allows you to easily clean the surface of the oven.

Easy-to-clean enamel is a smooth coating on the internal surfaces of an oven that has no pores. Grease and soot can be removed by wiping the walls with a cloth.

This coating saves the housewife from having to spend hours cleaning the oven, but still does not free her from washing surfaces by hand.

Difference from steam (hydrolysis)

The difference between steam and catalytic types of cleaning is very significant. It concerns almost all aspects of the technique.

What is the cleaning method for your oven?

HydrolyticCatalytic

Let's look at the differences between these methods:

for steam cleaning, a special procedure must be carried out, while catalytic cleaning occurs during cooking;- steam treatment softens deposits, and catalytic treatment decomposes fat into water and carbon;

- The composition of the layers for steam cleaning is not significant. With the catalytic method, only fat and its derivatives are processed. Melted sugar and milk can destroy catalytic enamel;

- the temperature created during hydrolysis purification is in the range of 50°-90°. For the catalytic method, a more severe regime is needed - from 140° to 200° (sometimes raised to 250°).

Steam cleaning occurs in a softer, more gentle mode. It takes about half an hour to heat up, plus the time required to remove the softened deposits by hand. The catalytic method does not require manual cleaning, although in practice it is still necessary to remove the remains of decomposed deposits or residues of other products that are not fat or its derivatives.

This is interesting: Glass ceramic hob: what is good and how to choose?

Catalytic method

Catalytic oven cleaning is a self-acting reaction that breaks down fat, soot and other substances formed during the cooking process. The process of decomposition of complex compounds into carbon and water is made possible thanks to special plates that cover the inner surface of the oven.

The operating principle of the miracle coating is based on the rules of chemical reactions in a hot environment. It is as follows: during cooking, when the temperature in the oven exceeds 200 degrees, the process of fat breakdown begins. Its course is characterized by the simultaneous removal of decay products, which becomes possible due to the action of nanoparticles.

The reaction proceeds due to the activation of a chemical catalyst, which begins to work automatically as soon as the temperature exceeds the above threshold. It should be noted here that the more the temperature in the oven rises, the more active the splitting process occurs. Its acceleration occurs with the help of copper oxide, cobalt and manganese, which play the role of main catalysts.

Grease-absorbing enamel is applied to all walls of the oven with the exception of the bottom and glass door. This is due to the fact that during the baking process, jam, jam, melted sugar, and milk components often flow down to the bottom of the appliance. By instantly burning on a hot surface, these products can harm the enamel coating, so the bottom of the oven is made of traditional materials.

This built-in self-cleaning function coats the inside of the oven with dark, rough enamel. If you look at it more closely, pores filled with a special chemical composition become noticeable.

When fat gets onto the oven walls during cooking, a reaction occurs under the influence of high temperature, and it quickly breaks down into water droplets and carbon.

Self-cleaning begins to work when the oven is heated above 150 degrees. The optimal temperature for quick cleansing is considered to be 250 degrees. The catalytic method helps keep the oven clean without the slightest effort on the part of the owner. After cooking, she only needs to walk along the inside of the oven with a damp cloth, collecting the ash that has formed as the fat breaks down.

To fully understand what catalytic oven cleaning means, you need to understand that with its help, walls coated with the composition absorb dirt like blotting paper.

Manufacturers producing such stoves do not apply porous enamel to the entire oven. She is situated:

- on the top, back and side walls;

- on the convector blades.

The lower wall is usually not treated with a special compound. This is due to the fact that porous enamel is damaged by sweet syrups and milk drips, which often fall down the oven when baking pies. Therefore, the lower part of the oven will have to be tidied up using cleaning products. This principle also applies to the door - you will also have to clean it yourself.

Advantages and disadvantages

Positive aspects

The catalytic method has its advantages and disadvantages. After studying them, you can understand whether it is worth choosing this oven option for home use. It turns out that in addition to the positive aspects of using the device, there are also negative ones.

The advantages of this version of the device are determined by several points:

- The automatic principle of processing internal surfaces due to chemical reactions that occur under the influence of high temperatures and catalysts applied to the plates.

- Economical in terms of energy consumption, since cleaning is carried out during cooking without additional connection to the network.

- Catalyst enamel can be used to cover the walls of electric or gas ovens.

- The quality of work on pollution is identical for all manufacturers. Much depends on the curvature of the surface on which the grease-absorbing enamel is applied.

- It is considered inexpensive when compared with ordinary products of this type, but from well-known and expensive brands.

Negative aspects

There are quite a lot of disadvantages, but they are not significant. The disadvantages of this type of cleaning can be identified as follows:

- The effectiveness of this type of processing is insignificant and does not give 100% results. Especially when compared with the mechanical option of cleaning the inner chamber.

- Additionally, you need to resort to manual cleaning of the surfaces of the inside of the chamber.

- The pan, rack guides and grill must be washed by hand or in the dishwasher.

- The bottom and inner surface of the door do not have catalytic self-cleaning properties. These elements are not coated with special enamel.

- In places where the enamel has been contaminated with dairy or sweet products, the enamel completely loses its “magical” properties.

- Effective only with frequent use. If you rarely turn on the device, the enamel begins to lose its properties due to a decrease in the activity of the catalytic composition.

- It cannot remove large grease stains in one go. When significant dirt remains on the walls, it will not be possible to remove it in one go. You will have to remove dirt with a rag and other cleaning products.

- Periodic replacement of plates is required. During use, they also need to be turned over, but this is possible if they are double-sided. After 4-5 years, the coating loses its unique properties.

By determining the significant pros and cons at the time of choosing a device, you can determine the need for such a purchase. Some positive or negative aspects in the operation of the device can mean quite a lot to an individual buyer.

For “lazy” housewives who cook in ovens, this device option is ideal. After each baking process, there is no need to clean the surfaces inside the chamber, since they “dissolve” on their own under the influence of substances and techniques that are safe for humans. In addition to the positive aspects in the operation of a device of this type, there are also disadvantages, albeit minor ones.

Features of hydrolysis oven cleaning

As the name suggests, hydrolysis cleaning is the dissolution of contaminants under the influence of water vapor.

As a result, the dirt softens and after the oven has cooled, all that remains is to rinse the surfaces, racks and baking sheets in running water, and, if necessary, clean with a sponge. This method requires much less time and effort than regular cleaning, but the need to use a sponge and fuss with soot can be considered a definite disadvantage.

The catalytic method involves the use of special enamel for coating. This material does not allow fat to “eat” into the surfaces and harden, which makes cleaning the oven compartment easier.

As mentioned above, hydrolysis is a cleaning method using water vapor, and with a catalytic system, surfaces get rid of plaque and carbon deposits due to the characteristics of the panel coating.

Both methods are used not only in electric, but also in gas units, and this is a plus.

We invite you to familiarize yourself with Filtration of vegetable oil on the ABC apparatus

Continuing the comparative analysis, we can say that hydrolysis saves money (there is no need to purchase cleaning agents), and the catalytic method saves physical effort when washing surfaces, since it neutralizes grease. In addition, the catalytic panels will have to be replaced over time.

Which method is better is up to the hostess to decide; in this situation, it all depends on personal preferences.

A distinctive feature of the method of removing food residues using steam is its versatility.

Getting rid of dirt using hot steam is effective only for fresh stains.

Hydrolysis is used in all types of ovens. This method is suitable not only for ovens, but also for microwave ovens.

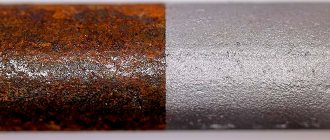

It should be taken into account that frequent use of hydrolysis causes corrosion of materials. To prevent this situation, you need to opt for models in which the coating is made using high-quality enamel.

Fat accumulations fall into a bowl of hot water. If there is a small amount of dirt on the walls of the device, they can be easily removed. To ensure high-quality cleaning that is safe for the coating, use a soft sponge or cloth.

The essence of the method is that water in a volume of 0.5 liters is poured into a heat-resistant vessel or oven tray. The liquid is heated at a temperature of 90 degrees. Hot steam softens all old dirt.

Be sure to read:

How to light the oven in a gas stove Hephaestus, Greta, Indesit and others

Some models use hydrolysis fluid instead of water. In addition, modern ovens are equipped with an activation function according to a timer, adjustment of cleaning intensity, and process duration.

After steam cleaning is completed, allow the unit to cool. Next, the remaining dirt is removed manually. Allow the oven to dry with the door slightly open for one hour.

The advantages of hydrolysis cleaning include several important factors:

- Low cost and simple process.

- Low level of energy costs.

- Eliminate the possibility of getting burned.

- There is no need to use aggressive, dangerous cleaning agents.

- Cleaning takes 15-30 minutes.

The method also has a number of disadvantages:

- The remaining softened dirt is removed manually.

- The method effectively removes only fresh dirt.

- There is a possibility of damage to the internal coating of the unit.

Some modern models are equipped with additional bells and whistles to improve the hydrolysis cleaning system:

- The “Cleaning” function consists of using special liquids for spraying. To do this, the device is heated to a temperature of 90 degrees. This indicator must be maintained for 15 minutes. After heating, a cleaning spray is applied to the surface. After the cycle is completed, any remaining grease and moisture is removed manually using a cloth.

- The "Aqua clean" function is used at low temperatures. To activate the program you need 0.5 liters of water. The optimal cleaning temperature is 50 degrees. The process takes exactly half an hour. After cleaning is completed, the oven is wiped with a cloth and dried. Place the pan back into the oven. In this case, the door must be open for at least one hour.

Pyrolysis, hydrolysis, catalysis - what is it?

There are several ways to clean an oven: pyrolytic, hydrolytic, catalytic. Let's take a closer look at each of them.

There are several ways to clean an oven: pyrolytic, hydrolytic, catalytic. Let's take a closer look at each of them.

Pyrolysis

Pyrolytic oven cleaning is an oven cleaning process that burns food debris to form ash. There is no manual work involved in cleaning the walls; the system does everything itself. During this process, the doors of the oven are blocked, the temperature inside is high, and the load on the appliance is also considerable. For the manufacture of such ovens, a special material is used that can withstand high levels of heat.

Pyrolytic oven cleaning is a high-temperature oven cleaning process that burns food debris to form ash.

Hydrolysis

During hydrolytic cleaning, dirt accumulated on the walls is softened. A container of water is placed on the bottom shelf, the oven is heated to the required temperature, the water evaporates, and the steam softens the dirt. This process is not automated; food debris will have to be removed manually.

During hydrolytic cleaning, dirt accumulated on the walls is softened.

Catalysis

This oven cleaning process is based on chemical reactions: special substances are added to the oven enamel, which act as catalysts and help decompose contaminants into simpler substances. Catalysis occurs at low temperatures.

This oven cleaning process is based on chemical reactions: special substances are added to the oven enamel, which act as catalysts and help decompose contaminants into simpler substances.

Advantages of the method

Like any other modern technology, catalytic oven cleaning has both strengths and weaknesses. The advantages of the method include a number of important points.

- Full automation of the cleaning process does not require human participation, which greatly simplifies the care of the oven.

- The low temperature threshold for starting the cleansing process, often only 150 degrees, allows you to get rid of fatty contaminants even when using the oven at low temperatures.

- Unlike pyrolytic cleaning, which is carried out after cooking and requires high temperatures and high energy consumption, catalytic cleaning is performed during cooking and does not require additional time and electricity. In addition, this method is much more effective than steam cleaning: it not only breaks down grease and other contaminants, but also removes them from the inner surface of the oven.

- This method is universal; it can be used not only in electric, but also in gas ovens.

- The catalytic cleaning function has virtually no effect on the cost of the oven.

- Pieces of furniture adjacent to the oven do not experience high temperature loads during cleaning, unlike, for example, pyrolysis models, for cleaning which the device heats up to 500 degrees.

The disadvantages of the catalytic procedure include lower purification efficiency compared to pyrolysis. This is due to the fact that only the walls of the appliance are coated, so the grate, metal sheets, grill and door will have to be cleaned manually.

It is also worth noting that special enamel loses its working qualities over time, which is why the plates have to be changed every 5 years. To extend its service life, it is recommended to wipe the enamel only with a soft cloth; the use of rough and rough fabrics is prohibited. However, to be fair, it is worth noting that removable panels of this type often have a double-sided coating. Therefore, if one of the sides loses its working properties, the sheet is safely turned over and used for another 5 years.

Among the disadvantages, there is also incomplete breakdown of fat when the oven is turned on for a short time. However, its final removal necessarily occurs when the device is reused. In this regard, this type of cleaning is more suitable for those who use the oven regularly.

Since catalytic purification is a simple chemical reaction, it does not require complex technologies or expensive components. Therefore, such a system stands out among developments at an affordable price. In addition, it has a number of other advantages:

- significantly saves time spent on stove maintenance;

- the oven does not need to be washed after each cooking;

- cleaning occurs while cooking, so it does not require additionally turning on the oven and wasting electricity or gas;

- The warranty period for the enamel is about 5 years.

We invite you to familiarize yourself with Plastic Cleaner

Over time, the protective coating wears off and must be replaced with a new one. In some models of equipment, the walls are treated with catalytic enamel on both sides. In this case, they need to be turned over to the new side. You can easily carry out the manipulation yourself, as the instructions describe the procedure in detail. But if a person is not able to cope with the work, the service center employees will quickly reinstall the walls.

When using catalytic cleaning, you do not need to select a special place in the kitchen to install the oven. The system works without interruption everywhere and does not heat the stove to such an extent as to damage furniture or other household appliances in the immediate vicinity.

Oven with catalysis: cooking and cleaning

Catalysis differs from other purification systems in that the process begins and occurs automatically , without human intervention.

Catalysis differs from other purification systems in that the process begins and occurs automatically

The side surfaces of the device, the back wall and the top are covered with a special porous, slightly rough enamel with particles of a catalyst that absorbs and breaks down fat into carbon and water.

The process of removing food residues occurs at temperatures from 140 to 220 degrees. Catalysis can be used in both gas and electric ovens.

Read more ► How to choose a gas hob: rating of the best models, what to look for when buying

How to use

Activation of cleaning occurs simultaneously with the start of the cooking process, which helps to significantly reduce energy costs. Splashes of grease immediately turn into ash, which can simply be removed with a rag.

The decomposition of dirt begins already at a temperature of 140 degrees. The maximum efficiency of the process is observed when reaching 220 degrees.

For catalysis to work, you do not need to enable any function on the control panel, since the entire procedure occurs automatically.

Benefits of catalytic cleaning

Catalysis has a number of undeniable advantages over other methods of cleaning the oven:

- Use in electric and gas ovens.

- Low energy costs. Cooking happens at the same time as cleaning.

- Long service life of the devices – at least 5 years.

- Affordable pricing policy. The cost of the oven does not depend in any way on the presence of catalysis in it.

- Easy replacement of panels at any service center.

Disadvantages of catalytic purification

Despite all the advantages, catalysis has its disadvantages:

- The need to replace panels after 300 hours of operation due to the loss of their cleaning properties.

- The cost of the oven depends on the quality of the materials used.

- Lack of enamel on the doors and bottom of the appliance.

- If there is heavy contamination, a repeat cleaning procedure is required.

- The panel may not function properly if sugar or milk comes in contact with it.

The principle of pyrolytic purification

Many buyers are interested in what is the difference between pyrolytic and catalytic oven cleaning.

The benefits of purchasing an oven with pyrolysis technology raise some doubts

Pyrolysis is the breakdown of substances due to exposure to high temperatures. Leftover food burns completely, turning into ash and soot.

The benefits of purchasing an oven with pyrolysis technology raise some doubts. Such models have the highest cost compared to other types of food residue removal. On average, the price category is 2 times higher than the cost of other middle-class ovens.

This is due to the quality of the material used to decorate the interior walls. The doors have additional protection against burns.

This type of cleaning is present only in electrical units. Pyrolysis is not economically viable due to the high level of energy consumption. When installing, it is important to consider that the power cable voltage must be 6000 V.

The exception is ovens with “6th sense” technology. Its essence is that the device reacts to the concentration of carbon dioxide, which is released during combustion. When its level begins to decrease, the process stops.

Pyrolysis has its economic advantages. Such ovens serve for a long time without breaking down and do not require frequent replacement of expensive parts. Most of these models are equipped with a self-cleaning function, which significantly reduces the costs required to purchase detergent.

How to use?

How to use an oven with pyrolysis function:

- Remove the kitchen utensils that are in it, take out the baking sheets and racks.

- Select the required mode on the control panel based on the degree of contamination, press the “Start” button. When the temperature rises to 300 degrees, the door will lock to prevent burns. It will be possible to open it again when the cleaning process is completed: the temperature begins to drop and reaches 200 degrees.

- After cooling, remove the resulting ash with a brush, then wipe the surface with a soft cloth.

When using the oven daily, pyrolysis is carried out at least once every 7 days.

Modern models are equipped with additional functions that will help make working with the device easier:

- The presence of a filter that automatically starts the cleaning process after 100 hours of operation.

- Built-in sensor system that tells the housewife that it is time to remove dirt.

- Step-by-step instructions for cleaning the oven, which are displayed on the digital display.

Be sure to read:

How to connect a gas stove with your own hands: step-by-step instructions, installation rules

Ovens with pyrolysis appeared quite recently, but during this time they have evolved.

| Mode | Purpose | Working hours |

| Minimum | Used in cases of light contamination | 2 hours 15 minutes |

| Ordinary | Medium difficulty | 2 hours 40 minutes |

| Maximum | If there is a thick or old layer of fat | 3 hours 15 minutes |

Gradually, almost every manufacturer of household appliances began to produce models based on the needs of customers and use a catalytic filter, which allows them to quickly burn large contaminants and save energy consumption.

Some manufacturers produce ovens in which food is burned in several levels. This allows you to avoid heating the device to maximum temperatures.

Pyrolysis ovens are the highest quality appliances.

This is explained by the fact that high combustion temperatures require appropriate quality material. For the manufacture of such devices, only the highest quality steel is used. The walls and bottom are covered with special enamel that can withstand high temperatures.

The door glass is completely safe. This is achieved thanks to the presence of 3 or 4 tempered glasses. The door locks during operation. The case is equipped with a cooling system, but it is important to consider that the temperature of the device can reach 100 degrees or higher.

There is a safety system inside the unit in case of fire. To do this, sensors are installed that record temperature and carbon monoxide concentrations.

Some brands of ovens have filters that are located on the convector grill. Their task is to protect the fan from contamination.

The oven's durable enamel can be cleaned with regular non-abrasive cleaners. This will help save energy costs.

Among the few disadvantages of this type of cleaning, an unpleasant odor should be noted. This is due to the fact that all residues burn to the ground at a temperature of 500 degrees, and soot is formed.

During cleaning, be sure to turn on the hood and open the kitchen window wide. To solve this issue, you can attach a pipe to the hole in the back wall of the device and lead it into the ventilation system.

If you have a catalytic filter, this problem should not arise. It is designed to operate during the entire service life of the device. Automatic filter cleaning occurs after every 100 hours of operation.

To reduce odor levels, cleaning should be done at least once a week if the unit is used frequently.

Comparison table of oven cleaning types

Each type of cleaning has its own advantages and disadvantages.

We suggest you familiarize yourself with How to remove lipstick from a coat

When making a choice in favor of one technology or another, you should consider:

- how often the device will be used;

- what price segment is acceptable;

- what should be the quality of the materials used;

- Is it important to fully automate the process or is minor manual cleaning allowed?

- what is the power of the electrical wiring;

- Do you have a powerful hood at home?

The pyrolysis model is convenient if it is possible to purchase expensive equipment, a wire with a power of at least 600 W is installed, and the kitchen is equipped with a powerful hood.

Hydrolysis does not require large amounts of electricity, eliminating the possibility of burns. The method is quite simple and cost-effective, but requires additional manual work to remove any remaining burnt fat.

If saving money is a priority, then the best option would be a gas stove with a catalytic type of removal of old contaminants, although this type of equipment is less functional than electric ovens. Catalysis is suitable for frequent use of the stove and will greatly facilitate the process of removing old grease and stains.

No manual oven cleaning

Catalytic cleaning of the oven is carried out in accordance with this principle - the decomposition of fat accumulated during the cooking process into water and soot. Decomposition products are absorbed by a sorbent consisting of nanoparticles. As for the oven coating, it has some features:

- The bottom of the cabinet is not coated with a special agent, so this part is not involved in the sewerage process. This distribution of enamel surfaces is spoiled by sugar and milk. Therefore, the bottom of the cabinet must be cleaned from dirt with a soft sponge and any detergent. This must be done in order to remove any remaining food.

- It is recommended to additionally purchase a grease-absorbing filter. After installing such an element, cleaning improves. The grease-absorbing filter needs to be cleaned periodically - it can even be washed in the dishwasher. First you need to make sure that there are no other dishes or food debris in it, as they can get into the filter cells. Then it will stop working.

- The grease-absorbing coating of ovens wears off over time. After 5 years of use, the side walls will require replacement. In some oven models, the side panels come with double-sided enamel for self-cleaning; after the end of the service life of one side, they only need to be attached with the reverse side. In this case, there is no need to purchase new walls.

Such features of the structure and operation of the components of the device make the oven unique. The remaining features lie in the unique operation of the “smart coating”.

Removing residues after basic cleaning

If you advise choosing this type of camera, then the user can be protected from painful hours of cleaning the device.

When does this impact on pollution occur? Cleaning occurs at the time of cooking as a result of exposure to high temperature to the chemical catalyst. The decomposition of fatty residues begins at a temperature of 140 degrees. The effect reaches maximum effectiveness at a temperature of 200 degrees.

Catalysis occurs during normal operation of the stove - there are no special modes to turn on. The process occurs automatically as a result of chemical reactions.

Note! This processing option is easier compared to the manual type of exposure to pollution. Although the second option (more traditional) should not be completely excluded.

Pyrolytic cleaning

There is also a pyrolytic principle of cleaning the surface of the oven chamber from the inside. Before deciding which option is better, it is worth understanding what pyrolysis is.

Pyrolysis is the process of thermal decomposition of organic and many inorganic compounds. In the chamber, during the pyrolytic cleaning process, fatty and other organic food residues decompose under the influence of very high temperatures.

The operating principle of pyrolytic cleaning of the device’s chamber is precisely the burning of fatty contaminants under the influence of temperatures above 500 degrees. Leftover food turns into soot. Burning residues produces steam with an unpleasant odor. A catalytic filter is used to eliminate unpleasant odors.

The Catholic steam filter does not need to be washed or replaced - it is designed to last the life of the oven and cleans itself automatically. The action occurs approximately once every 100 hours of operation of the oven by calcination.

It turns out that pyrolysis is more effective in comparison with the catalytic purification option. But in any case, additional manual processing is required. At the time of combustion, a disgusting odor may appear, which is not observed with the catalytic type of exposure.

Pros and cons of the procedure

Among the advantages can be noted:

- Automation of the process by applying a substance to the walls and fan blades, as well as maintaining the desired temperature;

- Cost-effective, because cleansing is done during the cooking process and without unnecessary effort;

- Use in absolutely any types and models of ovens at different cooking temperatures;

- The minimum threshold for the start of the process of decomposition of fats and soot starts at 150 degrees, while with other methods this threshold is much higher;

- The composition is the same for all manufacturers of the substance. The difference can only be in the time of action;

- Relatively cheap substance.

Of the minuses it is worth noting:

- There are many types of cleaning ovens in the world, and this method is the least effective (manual washing of the chamber is not taken into account);

- Like many other products, it does not completely eliminate the problems of cleaning the oven. Over time, the grease-absorbing coating has to be changed, first washing the entire chamber;

- Sheets, grates, grills and other tools will need to be washed by hand;

- The bottom of the oven and the door from the inside will have to be washed by hand, because... special material is not installed there;

- If sticky, sweet, fermented milk products and substances get on the plates, cleansing will not work;

- This method is most beneficial for frequent cooking in the oven. If you use the oven only a couple of times a month, this cleaning option will not pay for itself;

- Clean the enamel coating only with soft cloths. When using rough and rough material, cracks may form and the plates will lose their effectiveness;

- The cost and quality of the installed enamel plates directly depends on the type of oven. What is suitable for an electric oven may not be suitable for a gas oven and vice versa;

- The validity period of special plates is approximately 5 years. After the expiration date, they need to be replaced to make cleaning more effective.

To summarize, it can be noted that this method is attractive because of its low cost and availability.

Compared to other methods, catalytic purification does not require large amounts of electricity. Also, by using this type of cleaning, you can save a lot of time that would have been spent on washing the oven manually. Today, almost all modern furnaces have built-in protection against the deposition of organic compounds and soot in the furnace, and the catalytic cleaning method is one of the most economical. No matter how attractive this automatic cleaning option may be, you need to take into account the costs of the grease-absorbing coating, which needs to be changed periodically.

Advantages and disadvantages

Despite the positive reviews that the new development is receiving, it has several negative aspects. They must be taken into account when purchasing equipment.

- If, when frying meat, too much fat gets onto the porous enamel, the system does not always completely cope with its breakdown. Therefore, large dirty areas can only be cleaned after repeated use of the oven.

- Some pieces of equipment have to be washed the old fashioned way - by hand. This applies not only to the door and bottom wall, but also to the baking sheets, grill, and grate.

- When the walls of the equipment are not coated on both sides, purchasing new parts can hit the family budget hard. Their average cost depends on the brand of stove and ranges from 2000 to 4000 rubles.

Rating and cost of models

The price depends on the brand and other functions of the oven. Many well-known companies offer consumers high-quality models. Cost - from 26 to 52 thousand rubles. Elite options cost about 150 thousand rubles.

The best models of ovens of this type are offered by manufacturers from:

- Switzerland,

- Slovenia,

- Germany,

- Italy.

Market leaders:

- Electrolux.

- Hotpoint Ariston.

- Korting.

- Kupersberg.

- Bosch.

- Mile.

- Vestfrost.

- Gorenje.

- Siemens.

- Zanussi.

Manufacturers offer models with a stylish design, high functionality, and various color options for external surfaces. Stainless steel and tempered glass look impressive and modern and fit perfectly into the kitchen interior.

Available in black, grey, beige, silver, stylish “metallic” for external surfaces, a combination of elements of different textures and shades. There are many options for white: diamond, antique, pearl. The glass also has different shades, including beige, which in combination with “white pearl” creates a household appliance with a harmonious design for an interior in a classic style.

An oven with catalytic cleaning is the ideal solution for a busy housewife. You can cook baked dishes and, at the same time, get clean internal surfaces without spending extra time fighting grease. When choosing a model, you need to take into account the manufacturers' ratings and study reviews. It is advisable to find out the opinion of relatives, colleagues, and friends who have a modern oven with a catalytic self-cleaning function. You need to purchase models with a large number of useful options to make cooking and cleaning internal surfaces as comfortable as possible.

You can learn more about what catalytic oven cleaning is by watching the following video:

How to choose?

What does catalytic oven cleaning mean? This is a method whose effectiveness increases with regular use of the cabinet. Therefore, it is ideal for those who love to cook and constantly use the oven.

Every modern manufacturer of kitchen appliances has models with a built-in catalytic cleaning function. Its quality does not depend on the cost of the product, since porous enamel is made using the same technology and is purchased by slab manufacturers in finished form for processing the walls of products.

Electric and gas stove models are equipped with catalytic self-cleaning, but when purchasing, you should take into account that gas-powered ovens are less practical.

Types of catalytic purification system

This cleaning can be one-way or two-way. If we talk about double-sided cleaning, then in this case the manufacturer equips its oven models with panels that are coated on both sides with special catalytic enamel. When the time comes, you can turn the panel over to the other side, and this will extend the life of the oven. Therefore, it is recommended to replace panels every five years. The one-way system is less convenient.

You can easily get acquainted with popular types of catalytic cleaning systems on the Internet.

Advantages of catalytic cleaning:

- Quick and easy cleaning of gas and electric ovens;

- Cleaning stains and highly complex contaminants directly during cooking, without causing any damage to the prepared dish (and therefore saving energy);

- The walls and front of the oven do not heat up to dangerous temperatures;

- Chemical reactions, thanks to which cleaning occurs, save the housewife’s time on subsequent cleaning activities.

At the same time, you don’t need to think that the quality of cleaning is a consequence of the materials from which the stove is made. It is the relief surface of the walls that is important, and this may not be the case with the most expensive models. That is, a reliable cleaning system does not directly depend on price, which means that such equipment is accessible to many.