Water hammer is called the most common cause of emergency situations in pipelines through which any liquid circulates. Water hammer in a water supply system is a sharp and strong increase in water pressure, provoked by a rapid change in the speed of its flow. The first signs of this phenomenon are knocks and clicks, dull knocks, the appearance of leaks at the junction of elements of the plumbing system or leaking taps. The result of the impact of pressure surges is a violation of the tightness with destruction of the pipeline.

A crack in the pipeline caused by constant water hammer. Source uerria.witclub.info

Causes

Knowing what water hammer is in a water supply system, it is easy to identify the reasons for its occurrence. In this case, it is necessary to distinguish between negative and positive hydraulic shocks. The first occurs when water with high pressure enters a section of a pipeline with a sharply reduced liquid pressure. The second, more dangerous in their consequences, arise when pressure increases due to a rapid abrupt increase in the speed of its flow or, conversely, a stop. In practice this happens due to:

- sudden closure of valves or taps;

- turning on or off pumping equipment (including situations associated with a power outage);

- air jams;

- availability of pipes of different diameters.

It is worth noting that with the spread of ball designs of valves and faucets, the wear of water pipelines due to pressure shock has become more significant. Unlike the classic screw design, the ball design requires significantly less time for opening/closing shut-off valves. To do this, just turn the handle 90 degrees with one movement of your hand. And this, of course, is faster than several turns of the valve.

Ball and valve shut-off valves for hot and cold water supply pipelines Source nurai-invest.kz

The likelihood of water hammer is higher the longer the pipeline and the greater the potential volume of liquid that can collect in front of the shut-off valves or at the narrowing of the pipes.

See also: Catalog of companies that specialize in the calculation and installation of water supply and sewerage systems.

Is a water hammer damper really necessary?

Dmitry-Severodvinsk wrote: But we lived before this, and everything was fine for everyone.

We used to live without a lot of things. But before, “the trees were taller, the grass was greener, and the Earth was flat and stood on 3 pillars” (c). And if we get closer to the topic, there were no check valves, gearboxes, and at the same time electric valves (washing machine, PMM), ceramic axle-box valves and ball valves in apartments before. And the water pressure often left much to be desired. Now a lot has changed, but the laws of physics remain the same.

Dmitry-Severodvinsk wrote: And even if a thing is needed in the household, is it only needed on the cold water riser or on the hot water supply too?

Well, in theory, both here and there. But you have to look at it purely individually. For example, I don’t have one, but I also don’t have a check valve and the pressure never goes above 3.5.

bc—- wrote: in the context of an apartment it’s not needed, it’s more of a fashion statement. Especially when it is molded onto a collector, where it is not capable of absorbing any water hammer at all.

Why is this interesting?

bc—- wrote: with the amount of water we have in the apartment pipe, there is no harm from these water hammers.

no benefit at all

Source

Consequences of water hammer

Any incidents with the water supply are associated not only with material damage to the pipeline itself, but also with the costs of eliminating the consequences of water exposure to nearby objects. This is especially aggravated for pipelines with hot water and those under high pressure. In these situations, there is even a danger to the health and life of people and pets. They may be scalded or injured. In particular, this negative phenomenon may be followed by the following:

- destruction of pipe lines;

- flooding of residential, administrative and utility premises;

- failure of pumping equipment and shut-off valves;

- damage to furniture, household appliances, computers and the like;

- interruption of water supply;

- destruction of structures of buildings and structures (especially in winter, due to the force of expansion when moisture freezes);

- interruption of electrical supply;

- fires due to short circuit of electrical wiring.

Danger of consequences of damage to heating and water supply due to water hammer Source formp3life.ru

Accidents on highway networks can cause traffic congestion; in winter, icy conditions caused by gusts usually completely block the movement of cars for some time.

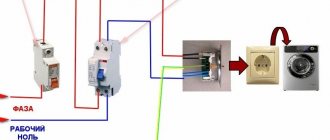

How to install

Miss Clean magazine strongly recommends entrusting any work with pipes, especially with risers, to specialists. They will carry out the installation efficiently and quickly.

General rules:

- the shock absorber is installed on a certain length of pipe (for example, under the ceiling of each odd-numbered floor);

- the best option is when the compensator is located in front of the valve, faucet, valve of household appliances, faucets, and other consumers;

- it is also permissible to place the compensator after the collector outlets (i.e. after the check valves) in the apartment (see below photo from S. Savitsky’s blog “Ideas for Repair”);

- if a gearbox is placed, the compensator follows it;

- the compensator must be located directly on the pipe or on a corner transition, and not on its dead-end branch (see photo below);

- the shunt is installed strictly in the direction of water flow;

- the regulator or valve is placed near the controller and connected to it.

Okay, we figured out the pipes and risers. What to do if the house has an electric storage water heater or a gas water heater? The former are usually equipped with their own safety valves. In the case of a “column” or any other instantaneous water heater, the compensator should be placed after the unit - this will extend the life of its hoses and seals.

Prevention and protection

Prevention and protection against water hammer is based on two things. This is correct operation and direct protection against water hammer in the water supply system. The first primarily comes down to minimizing cases of instantaneous changes in flow speed due to incorrect human actions. To do this, all switching on and off of the pipeline must be done smoothly, ensuring a uniform change in pressure over a certain period of time. Preventive measures also include checking the system for leaks, regularly replacing and cleaning filters, and checking the functionality of water supply elements.

Other ways to combat water hammer

One of the possible options for neutralizing water hammer has already been voiced - close the taps smoothly. But this is not a panacea, and it is inconvenient in our fast-paced times. And there are also household appliances, you can’t teach them. Although, some manufacturers take this point into account, and the latest models are made with a valve that smoothly shuts off the water. This is why compensators and neutralizers are becoming so popular.

Water hammer compensator - a small device (comparison with a brass ball valve)

You can combat water hammer using other methods:

Water hammer is a truly dangerous thing for a closed system. He breaks radiators and bursts pipes. To avoid problems, it is better to think through control measures in advance. If everything is already working, but problems arise, the smartest and easiest way is to install compensators. Yes, they are not cheap, but repairs will cost more.

Technical means of protection

The system must be maximally protected from rash human actions, improper operation and untimely and incomplete maintenance. To achieve this, there are a number of technical solutions to minimize the consequences of fluid pressure surges in water supply and heating networks and prevent their occurrence.

Pipe replacement

To do this, it is necessary to inspect the entire pipeline; old steel pipes should be replaced with modern ones made of polymer materials. They are more reliable, practically resistant to corrosion and last longer. In this case, pipes must be selected taking into account operating conditions (pressure and temperature in the network) with a small margin in parameters. To reduce the flow rate, it is advisable to choose products with the maximum possible diameter for the pressure. Find a middle ground.

Modern reliable pipes and connecting elements made of polymer materials Source santehnika-nk.ru

Replacing shut-off valves

Replacing ball valves with valve valves can be called a return to the past, but this will avoid sudden pressure changes regardless of how the shut-off valves open and close. It is not necessary to change all locking devices; you can limit yourself to only those that are critical to the system.

Varieties

There are several types of current device classifications. The most practical is considered to be grouping according to the types of membranes used. Today, almost all devices are produced with a diaphragm membrane. The cylinder is non-separable, made of durable steel. Usually consists of two hemispheres welded together. The membrane is mounted in such a way that the cavity of the tank is divided into two parts. The connecting pipe remains in one part, and the spool in the other.

The balloon membrane must be replaced. But modern materials are able to withstand increased loads for quite a long time without loss of integrity and elasticity, so the need to replace the membrane has practically disappeared. The reservoir for the balloon membrane is dismountable. The water is contained in a rubber chamber and does not come into contact with the inner walls of the tank. The spherical membrane is practically not used today; it is considered a rarity.

Water hammer compensator in internal water supply systems FAR

—>

| Name | Size | Retail price, rub. | Discount price, rub. | |

| Water hammer compensator in internal water supply systems FAR FA 2895 12 | 1/2″ |

You can download the full price list for FAR valves in Excel format here.

The phenomenon of “water hammer” occurs in the event of a sudden opening or closing of equipment (mixing tap drive, pump, etc.), which leads to the appearance of excess pressure in the system. The FAR water hammer compensator takes on excess pressure, maintaining normal operating parameters for system components. Its task is also to significantly reduce noise from vibration that occurs as a result of closing the water consumer.

Characteristics

- Connection - HP 1/2″;

- Maximum pressure - 50 bar;

- Nominal pressure - 10 bar;

- Maximum operating temperature is 100°C.

Design

1. The upper part of the body is CW617N brass; 2. Spring - AISI 302; 3. O-ring - EPDM; 4. Disk - plastic; 5. The lower part of the body is CW617N brass; 6. Clamping ring - brass CW614N; 7. Seal - EPDM.

Principle of operation

Reduction of excess pressure occurs through an air chamber and a steel spring connected to a plastic disk having a double seal, which absorb most of the excess pressure.

In the open position of the consumer, the pressure in the pipeline remains constant.

When the consumer is closed, the pressure in the pipeline increases, and the FAR water hammer absorber absorbs the excess pressure, protecting the system components.

It is recommended to install the water hammer compensator at the end of the pipeline to consumers (ball valves, plumbing fixtures, motorized valves, etc.) or on manifolds.

An example of installing a water hammer compensator on Multifar collectors.

An example of installing a water hammer compensator at a consumer.

The water hammer compensator can be installed vertically or horizontally.

When installing a water hammer compensator, you need to make sure that its location does not create areas where stagnation of water can occur, which leads to the growth of bacteria. For example, you should avoid installing an expansion joint at the top of the riser.

Design of safety valves

Depending on the operating conditions and purpose of the valve, they may differ in a number of parameters: standard size;

- body material (cast iron, bronze);

- material of the shut-off membrane (natural rubber, reinforced nitrile rubber);

- type of connection to the body (flange, threaded, quick-release-victaulik);

The design orientation of the rod and diaphragm can be:

- vertical – equipment of series 100 and 300;

- inclined – series 500.