A common malfunction is the washing machine door not locking. Modern SMAs are designed in such a way that they will not work without closing the door. This is done for safety to prevent damage from the spinning drum, scalding from hot water, and in the case of front-loading machines, flooding.

- Causes

- Hatch locking device

- Wiring

- Module

- "Aquastop" system

- Mechanical failure of the reverse part

- Washing machine catalog

Causes

Let's consider the possible reasons why the door does not lock:

- UBL (hatch locking device) is faulty;

- wiring is damaged;

- the control module has failed;

- the Aquastop system was activated;

- The lock mate is broken.

Every fault needs to be diagnosed. Let's take a closer look at this work.

Washing machine hatch

How to fix the problem?

Hook lock

On washing machines, the hook that is inserted into the lock for subsequent locking is held on a metal rod. Over time, the rod moves out of place and the hook moves and does not fit properly. The blocking cannot work in this case. For the same reason, the door may not close at all.

To fix this, you need to remove the hatch, unscrew the screws around the perimeter of the hatch, halve the hatch and put the rod in place where it is attached.

Video instruction: returning the hook to its place on the Indesit WIU61.

Luke

All hatches are made of plastic, and the hinges on which the hatch is held are made of metal. Over time, the metal begins to eat away at the plastic due to friction and backlash appears . The positions of the hatch and the hook are shifted, in which case the hook cannot get into place, the same thing happens when the rod is displaced, which we considered earlier. In such cases, the hatch itself or its parts responsible for holding the hatch in a certain position are replaced.

To troubleshoot:

- Remove the hatch.

- Unscrew the screws around the perimeter and halve it.

- Replace the damaged parts with new ones and reassemble the hatch in reverse order.

Opening mechanism

The opening mechanism includes: a hatch handle, a hatch hook, a spring and a rod on which the hook is held. If any of these components fail, the hatch will not lock or open .

To fix this problem, you will have to disassemble the hatch and replace the broken part. Most often it is the hatch handle.

For this:

- We remove the hatch.

- We unscrew the screws around the perimeter of the hatch.

- Let's halve it.

- Remove the broken handle.

- We put a new one in its place.

- Reassemble in reverse order.

Video instruction: replacing a broken hatch handle on an Indesit WS105TX.

Hatch locking device

Damage to the UBL is a common reason for the hatch not locking, so we start diagnostics with it. The principle of operation is simple - when voltage is applied, the lock first presses the lock hook, and then sends a signal further (to the module or another element), depending on the electrical circuit.

The machine begins to perform the following steps of the wash cycle. Typically, the drain pump is checked first and then water is supplied.

There are two types of this device:

- thermal lock;

- electronic.

Are you unplugging your washing machine?

Oh yes! No

Thermal UBL works according to the following principle:

- 220 volts are supplied to the contacts of the RTS resistor;

- it heats up and nonlinear expansion of the bimetallic plate occurs;

- the plate blocks the hook and closes the control contact, which sends a signal to the control module.

During the washing period, the lock is constantly under voltage, and this leads to gradual wear of the resistor, or damage to the contact group inside due to thermal effects. Based on the description, it can be understood that the lock has two functions: to block the hook and send a control signal.

One type of thermal lock

That is, during diagnosis we check both roles. Repairing the UBL is possible, but it is highly undesirable - this is a temporary measure. It is necessary to purchase a device that corresponds to a specific model of washing machine.

All diagnostic work is carried out using a tester and manually applying voltage to the resistor. There is resistance at its contacts.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

After applying voltage, you need to use a screwdriver to move the tongue that interacts with the hatch hook. Thus, we will, as it were, close the hatch.

Electronic locking works on a similar principle, but is controlled by pulses coming from the module. Manufacturers make different versions of such devices:

- available with two resistors;

- with electromagnet;

- and there are also options where a winding of high-resistance wire is used instead of a resistor.

Electronic UBLs are very difficult to diagnose. For this you need an oscilloscope. The easiest option is to install a new, known-good lock. If the door began to block, then the problem was with him. If there are no changes, check the following reasons.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! It is strictly forbidden to bypass the UBL in the electrical circuit! This is dangerous and may lead to an accident!

A simple thermal lock costs 300-500 rubles as of 2020. It's not worth taking risks for that kind of money.

Testing the UBL and changing it

But a door that does not close does not always require immediate replacement of the UBL. Before changing the blocker, you need to make sure that it is faulty. To evaluate the performance of the device, you will have to remove the device, inspect it and check it with a multimeter. We act like this.

- We disconnect the Indesit washing machine from all communications, including sewerage and water supply.

- We open the hatch. As a rule, if the mechanics worked perfectly, the door remains closed. Then we unlock it manually: unscrew the top cover, tilt the washer back, stick your hand to the lock and try to move the latch to the side with your index finger. You can proceed in a similar way from below, after first removing the bottom.

- Loosen the outer clamp on the cuff and tuck the elastic inside the drum.

- We find the lock, loosen the holding screws and take it out.

- Disconnect the wires connected to the UBL.

- We take out the UBL.

There is no need to try to repair a faulty UBL. Firstly, it is useless with disposable blocker parts. Secondly, the new device is inexpensive. In order not to make a mistake with the replacement, you need to tell the Indesit serial number in the store. Installation will not cause any difficulties: just act carefully, do not forget about safety precautions and follow the instructions described.

Wiring

Damage to the wires is possible due to the constant heating that is inherent in the operation of the door lock. A multimeter is used to test all the wires coming from the lock, as well as the contacts and chips.

The work is simple, but often everything in the car is twisted into a bundle and wrapped with electrical tape. This is especially true for Samsung and LG washing machines. The Koreans calculate everything down to the millimeter. Everything needs to be unwound and checked!

Wires in the washing machine

Washing machine door hinge repair

Greetings! That's how I fixed it. Suspension for gypsum boards to help. All the best to all and the joy of technology!

Repair Community

6.1K posts 35.5K subscribers

Community Rules

Posts with requests for help in repairs are created in the subsidiary community: https://pikabu.ru/community/HelpRemont

Only thematic articles with the tag “Equipment Repair” are allowed for publication.

In the community, only two things are strictly prohibited and punishable by ban:

Otherwise, the basic rules of Pikabu apply.

Cold welding on an aluminum alloy is pointless. the author has the most normal option

Well done. I am not kidding. Saved 1000 rubles

Or blue electrical tape.

I was able to restore laptop hinges (and they, as you know, have friction springs) using regular soldering with flux and pins crossing the fault plane (where possible). It turned out neatly and reliably. And there's effort - oh-ho!

and when the ubl grunts, hang the latch on the hatch?

It looks like Vestel or a similar shmurdyak, I buy such loops from the supplier for 200 rubles, and charge clients for 3000, plus or minus, depending on my mood.

The same happened with the washing machine, but the hinge on the handle to open the door broke. Everything is plastic. I drilled 2 holes in the remaining parts, twisted pair wire, removed the insulation, folded it in half and inserted it into the drilled holes. I tightened it with flats, added flux and soldered it (so it wouldn’t unravel and it would be stronger). It's been working for a year now)

The chooks at the reception have already begun to flap their wings - China, no nada. The chocks began to call the alloys china and shit. We made it.

How do I solve the problem of torn hinges on a laptop?

Good day everyone!

I have been repairing digital equipment for a long time. In total, more than 10 years of experience. I have been living in Italy for the last 9 years, of which 4 years I have owned a small service for repairing computers, phones, tablets, etc.

The other day, an ASUS UX303L laptop was brought in with the display hinges torn off. This is a nice computer, with a 13.3-inch screen and a metal body (sort of like a Macbook from Apple).

Module

The control board is a reliable element of the washing machine, but it burns due to overloads that occur both inside and outside the machine. Based on the operating principle of the locking lock, damage is not uncommon here. In this case, two options are possible:

- new block;

- repair.

Buying a module is not so simple. You need to find a specific board that matches the car model. In addition, it needs to be “flashed”, that is, filled with a program using special equipment, which again suits the brand. In addition, you cannot confuse the cables and wires that are connected to it.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Repairing a damaged module is cheaper. This is the most pragmatic option.

The problem just arises with finding an intelligent electronics specialist, especially in small towns. If there is no choice, and you are sure that the problem is in the module, then you can order it online.

But in this case, it is often more profitable to buy a new washing machine. Because the cost of electronic boards for the most common models ranges from 5,000 rubles to 15,000 rubles. Sometimes more.

Electronic module SMA

Repairing the locking mechanism

If the door does not close tightly, then there is suspicion of deformation of the latch lever. More precisely, irregularities appear on the part, which prevent the hatch from being fixed in the locking mechanism. It's easy to fix the situation:

- remove the door according to the algorithm described above;

- unfold the hatch with the latch towards you;

- take a file and grind off all the existing nicks and irregularities;

- lubricate the surfaces with graphite lubricant for prevention;

- we return the door to its place.

When problems with closing the hatch are caused by sagging hinges or loose fasteners, you need to adjust the position of the door hinges. But here everything is determined by eye: we twist and tighten the fasteners until they fit completely into the grooves.

This is interesting: Why does the refrigerator click and crackle when turned on and running?

"Aquastop" system

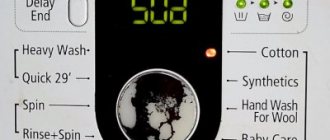

Some washing machines are equipped with a leak protection called AquaStop. This system is triggered when water appears on the SMA tray and prevents a new wash cycle from starting. Usually an error corresponding to this position is displayed.

Some brands, including Bosch and Siemens, equip the inlet hose with leakage protection. In this case, they talk about a complete “Aquastop”.

If such protection works, then you need to call a repairman and determine the cause. After all, a leak is an emergency.

In any case, it is necessary to open the machine body and dry the pan. If the error indicating a leak continues to be displayed, then it must be reset. Each brand does this differently. As a rule, this is described in the user manual.

Electrical and electronic faults

There are times when the washing machine door closes and the latch is working, but the lock still does not work. This means that the problem lies in the electronics. There may be several reasons:

- UBL breakdown;

- getting into the debris blocking device;

- control module failure.

UBL malfunction

Absolutely all modern washing machines have a hatch locking device (UBL). It protects the machine door from opening during washing. There are two types of UBL:

- electric locks operating on electric magnets;

- thermal locks operating thanks to biometallic plates.

Thermal locks are stronger and more durable, which is why they are used in most devices.

Inside such a lock there is an element that heats up when the machine is turned on and voltage is applied, as well as a metal plate. Due to the thermoelement, it heats up and bends, thereby blocking the door. After the hatch is closed, a contact is activated, which sends a signal to the control unit and the washing begins. If the process has not started, then there are problems in the UBL device. This problem is quite common in Indesit washing machines.

In order not to disassemble the device in vain, you can check the functionality of the locking device. To do this, you need to turn on the machine and try to start the wash without putting laundry in the drum. If the door is locked and a click is heard, then everything is in order with the UBL. Otherwise, you need to remove the device from the washing machine and repair it.

The most common cause of failure of the locking device is the loss of performance of the plate. Due to frequent changes in the temperature of the plate, its surface is destroyed. The lock can be locked both open and closed.

To repair or replace the locking device, you must:

- Using a screwdriver or pliers, remove the clamp on the cuff.

- Remove the cuff.

- Unscrew the screws on both sides of the lock.

- Remove the lock from the hole between the drum and the outer wall of the machine.

- Disconnect the connectors with wires.

- Connect a new lock to the wires.

- Put the part in place.

- Return the cuff.

- Run a test wash.

To make it easier to remove the lock, you can press on the machine body and tilt it back, so the drum will not put pressure on the cuff.

Damage to wiring

If the wiring in the washing machine is faulty, not only will the hatch not be blocked, but it will also periodically knock out plugs in the house. Sometimes the washing machine gets electrocuted.

Each washing machine consists of main electrical components:

- engine;

- sensors;

- pump;

- selector;

- control module;

- heating element.

There can be many reasons for wiring failure. The most common of them are:

- Drum clogged with debris;

- The filter is clogged, causing water to not be collected or drained;

- Damage to the drive belt;

- Pump jammed.

If the washing machine does not block the door and does not turn on, and the lights on the display do not light up, then you need to:

- Check the connection to the outlet. You can also make sure there is voltage at the outlet. If it is not there, then you should disassemble the socket and check the wires for integrity. And to start the wash, you can use an extension cord and another outlet.

- Check the integrity of the machine cord. To do this, you need to disassemble the machine and find the place where the wire goes. If there is no voltage at the ends of the wire, it should be replaced.

- Make sure the control unit is in good condition. To do this, you need to measure the voltage on the board. If the voltage on the board and the network are the same, then the board is damaged. This may happen due to a blown fuse.

- Inspect the board for burnout. If the tracks are damaged, they need to be replaced.

- Check the washing mode selector. Sometimes the contacts of a part burn out or rot.

Online diagnostics of a washing machine

If your machine stops washing or rinsing clothes normally, then some kind of malfunction or breakdown has occurred.

You can try to find the problem yourself. Run diagnostics

Select which operation your washing machine does not perform:

1. Doesn’t drain 2. Doesn’t rotate the drum 3. Doesn’t spin clothes 4. Noises, knocks, buzzes when spinning 5. Doesn’t turn on

Checking the operation of the drain pump Is the drain pump of the washing machine working? Yes No I don’t know << Back

Clogged hoses in the washing machine If the sound corresponds to the normal sound that has always been observed when the device is working, the cause is probably a clog.

Was there a blockage in the drain hose? Yes

<< Back

The drain pump does not work! If the sound matches the normal sound of the drain pump, it is recommended that you check the drain filter first.

After cleaning, does the drain pump work and does the washing machine drain water? Not really

<< Back

Operation of the drain pump The sound of the pump is usually immediately audible and noticeable. If there is no sound, the pump is not working. We are looking for how to separately enable the water drainage program. As a rule, this is a separate option. After the program has been turned on, the pump should start working in 1-3 seconds. If everything is done correctly and the pump is operational, a buzzing sound will appear. If you hear no buzzing or other sounds when you turn on the program, the pump is probably faulty.

Is the washing machine drain pump working? Not really

<< Back

Clogged car hoses If you have identified a clog in the hoses, you need to disassemble them, clean them, and then reassemble everything.

Does the washing machine drain well? Not really

<< Back

Hurray, you did a great job, you fixed it.

<< Return to the beginning of diagnostics

The drain pump is faulty, call a professional.

<< Return to the beginning of the diagnosis.

The washing machine does not rotate the drum. During the operation of the washing machine, such a problem may occur. Each model has a different drum operation. It rotates according to a given algorithm, which is set by the program. This principle applies to spinning and washing. If you are not sure whether the drum is not spinning or whether it is working, put the laundry in the washing machine. Start the spin program. If the machine is running, it will first drain the water and then start spinning. In this case, a rotational process will be observed. If rotation is not visible, then check the belt. First, turn off the program, then unplug the wire from the outlet so that power does not flow into the device. Now you need to remove the back cover. You will need to carefully inspect the drum belt. It is quite easy to determine whether it is in the wrong position or damaged.

Is the washing machine belt torn or stretched? Not really

<< Back

Broken drum drive belt If the belt breaks, it will be immediately visible. There are also often cases when the belt simply stretches, which is why the drum, accordingly, does not rotate. Do not allow the machine to operate if the belt breaks. It is important to check whether it has wound around the engine pulley or broken the wiring to the engine. The heating element and temperature sensor may also be damaged if the belt does catch the wires. It is imperative to ensure that the belt model is original. If you choose an unsuitable or low-quality product, this will affect the performance of other devices. How do you know what kind of belt you have? There will be a marking written on the old one, compare it with the one indicated on the belt offered to you. You can also find out belt information by car model.

<< Return to the beginning of the diagnosis.

Washing machine motor malfunction If a malfunction is not found, the block with wires must be disconnected from the electric motor. Carefully remove it. We visually evaluate the engine. It may have melting, cracks, or other effects that clearly indicate damage. We call the windings of the tachogenerator and the engine. It is important to understand that you can fully study how correctly the engine operates and whether there is a malfunction only at the stand. If rotation does not occur, there may be a problem with more than just the motor. Sometimes the cause is a malfunctioning electronic module. If a short circuit occurs in the engine, the module could be damaged, while the engine remains operational. Also, the wires could be damaged.

<< Return to the beginning of the diagnosis.

Repairing a washing machine that does not spin clothes After completing the washing process, the washing machine may not spin properly or may not start spinning. Firstly, look, perhaps another mode is set, which does not involve turning on the spin cycle at all. This happens, for example, with programs related to washing woolen items and delicate fabrics. To check, run the spin cycle separately. If the washing machine does not drain water, we proceed to check the pump.

Does the washing machine now spin clothes? Not really

<< Back

Congratulations, you have solved your problem!

<< Return to the beginning of the diagnosis.

Repair of washing machines, imbalance Modern washing machines place the laundry on the drum before spinning. This is necessary for quality work. Check if this feature works. Sometimes a situation occurs when things get wrapped up in a ball that cannot be unwound automatically within a certain time. At this point the work stops. You need to unwind this laundry yourself, lay it out and continue operating the washing machine. In this case, it is important to turn off the machine, and then, when the laundry is laid out, turn on a separate spin program.

Does the washing machine now spin clothes? Not really

<< Back

Washing machine repair, drum drive repair Now you need to check the drum drive belt. We remove the cover and visually assess the condition of the belt. There should be no damage. If the tension is weak, the spin may not turn on. If you need to replace the belt, you should only replace it with the original one. After replacing, we try the program again.

Fault found, does the washing machine spin? Not really

<< Back

The engine or electronic module is faulty, call a repairman to your home.

<< Return to the beginning of the diagnosis.

The washing machine hums, makes noise during the spin cycle, rumbles, and makes a jet plane noise. If the washing machine makes noise during operation, making unusual sounds, it’s time to pay special attention to it. In this case, a visible breakdown or lack of functionality may not be observed, but the appearance of strange sounds indicates that it is time to look for a malfunction. It is important to understand that a new car that has just been delivered should be inspected for shipping bolts. If you forget to remove them, noise and vibration are inevitable. So, let's begin! We turn the washing machine drum and listen to extraneous sounds.

When rotating, do you hear extraneous noise, hum, balls rolling, does the drum move unevenly with slight jamming? Not really

<< Back

If the drum rotates and uncharacteristic sounds appear, including vibration, it’s time to check the bearings. If they malfunction, they will have to be replaced.

<< Return to the beginning of the diagnosis.

The counterweight of the washing machine has come loose. The fastening of the counterweights must also be of high quality. If they are “loose”, it’s time to eliminate this defect. In some cases, you can notice that the bolts that secure the stones are completely missing. In this case, the connectors for mounting will be visible. The bolts need to be found and put in place - they probably simply came loose. A rumble heard while the washing machine is operating may indicate that the bolts have partially loosened. To check the bolts, you can simply push the drum. If it is secure, the bolts are fine. If it moves, there is a defect.

Do you hear any noise, clanging or rattling noises when moving the washing machine tub? Not really

<< Back

The counterweight has come off

<< Return to the beginning of diagnostics

Checking the shock absorbers of the washing machine Checking the shock absorbers. If you hear vibration or excessive noise during the spin cycle, there may be a problem with the shock absorbers. Sometimes the washer moves. Now let's check the functionality. Remove the top cover. Click on the tank, move it five to seven centimeters down. A normal reaction will be observed if the tank rises sharply, jumping a little and stopping in its normal place. If this does not happen, the shock absorbers need to be replaced.

Are the shock absorbers of the washing machine working? Not really

<< Back

If a visible defect has not been identified, check whether a foreign object may have entered the machine. Replacing shock absorbers. The problem with shock absorbers wearing out occurs quite often over time.

<< Return to the beginning of the diagnosis.

Replacing washing machine shock absorbers. Malfunction and wear of shock absorbers is a fairly common phenomenon.

<< Return to the beginning of the diagnosis.

The washing machine does not turn on. It is worth trying to find the cause of the problem yourself and fix it. We start by connecting the device to the network. Next, click on the “network” button. In different car models, different indications are triggered: here either the display will start working, or, on the contrary, some other button.

Does the washing machine have an indicator? Not really

<< Back

Hatch lock lock (UBL) You can check it by turning on any of the programs. We choose what we will use. Click on the corresponding button. Don't forget to pay attention to the inclusion. As a rule, the process of activating a function is characterized by the presence of a certain sound, for example a click, with which the device makes it clear that pressing again is not necessary and the machine is already working. If there is no sound, the button may be broken. In this case, the main thing that must be done is to block the hatch and start working. If this happens, everything is fine.

The washing machine is blocking the hatch and the UBL is triggered? Not really

<< Back

Water fill valve malfunction

<< Return to the beginning of the diagnosis.

The washing machine hatch does not lock

<< Return to the beginning of the diagnosis.

No indication Checking the electrical circuit. If you notice that the washing machine does not respond to being turned on, it is first recommended to check the power supply. The outlet may be faulty. Try connecting another device. If the outlet works, you need to check whether the circuit that conducts energy through the washing machine from one element to another is intact. To do this, you will need a multimeter, which will help you fully analyze the ability to respond to an electrical signal at several stages of operation. If there is no network connection anywhere, this is probably the problem. We carry out this manipulation until we reach the electronic module. If we are talking about an old washing machine, here it will look like the device’s program. When you turn on the button, there should be no breaks in the circuit. If the circuit works, everything is fine electrically.

Is the washing machine's power supply OK? Not really

<< Back

Repair of electronic module (unit)

<< Return to the beginning of diagnostics

Contact circuit fault

<< Return to the beginning of diagnostics

UBL with temperature sensor

When electricity is supplied, the UBL locks the hatch in the closed position. It closes the contacts of the switching device and signals that the wash can be started. A special lever mechanically secures the lock. This lasts the entire wash cycle.

And at the moment when electricity stops supplying to the locking device, you need to wait about 2-3 minutes. The latch then retracts and allows the door to be opened.

How does the locking device work?

A resistor is involved in the operation of the UBL. Its resistance increases as its heating increases. This effect causes the two plates that are located in the lock to change their shape. This produces a displacement of the lever. The lever closes the contacts of the switching device.

At the same time, the latch connected to the contact plate moves, creating a fixation of the hatch door. The entire process occurs within a few seconds after the electricity is applied. When the power supply is interrupted, the temperature sensor cools down. Cooling takes 1 to 3 minutes. After which the plates take their normal shape. The contact is no longer closed and latching is terminated.

Mechanical failure of the reverse part

Such damage is typical for SMAs equipped with thermal UBL. This is the simplest door locking device, based on a thermal plate and typical for inexpensive machines. The main disadvantage is that the plate needs time to cool down and return to its original state, thereby releasing the hook.

Broken back of the hatch

As a rule, this takes 2-3 minutes. Almost all cars have a light indication that the door is closed and cannot be opened. But users, in the hustle and bustle, forget about this and begin to pull the door handle ahead of time. The hook is metal, and the handle on the hatch is plastic.

This is done to prevent electric shock. The fact is that the hook is in contact with the lock, through which current constantly passes during washing. That's why the handles are made of plastic.

Due to constant tugging, they break and need to be replaced. This position is easy to determine - with the hatch open, move the handle. If the hook does not move, then the mechanism is broken.

The design of the UBL will be discussed in another article.

Video on checking the hatch locking device.

Note that this approach is applicable to different SMA brands, for example: Electrolux, Zanussi, Ariston, Indesit, (Wirlpool), Kandy, (Hansa), Gorenje, Ardo, "Beko", "AEG", (Miele), "Kaiser" and "Atlant".

How to fix the situation

If the door does not close tightly, and after inspection you find that the tongue or guide is misaligned, you need to replace it.

What should I do if the SMA display says that the door is not closed? This means the electronic lock is not working. Indicators on mechanical panels may flash. The UBL device needs to be replaced.

- Open the hatch door and unscrew the two bolts securing the device.

- Bend back the sealing rubber.

- Remove the clamp and tuck the cuff inside the drum.

- Take out the UBL device and disconnect the wiring from it.

Inspect the wiring. If burnt parts are visible, it needs to be replaced. The UBL is checked for resistance with a multimeter. If the lock is faulty, replace it in reverse order.

What you can do yourself

Often the car does not close for simple reasons:

From the practice of masters! If there is a small child in the family, small Lego parts, candies, chewing gum, candy wrappers and other items often end up in the UBL slot. This results in the washing machine door not closing.

Have you checked how the laundry is lying, whether there is any debris in the groove, closed the door more tightly and even turned off the machine, but nothing has changed? This means that the reason is still a malfunction, and your equipment needs professional help.

External damage

The lock may not close due to normal wear and tear or rough handling. For example, sometimes wet things are hung on the door, which with their weight can damage the mechanism. Damage may also occur if the unit is closed with excessive force.

The device may not close for several reasons:

Identifying this type of fault is not difficult. To check, you can perform a test closure in normal mode, without loading laundry. If the door does not close under such conditions, it means that the lock has broken down or the fastening is skewed. Sometimes this may be due to improper installation, and then in an uneven position the hatch may warp under the influence of weight and vibrations. How to install a washing machine correctly - read here.

You can debug the operation of the machine yourself. Carefully inspect the device and locking mechanism. Check:

Problems with the lock hook

The machine door is locked with a hook that ends the shutter rod. It is this hook that should fit into the socket and secure the structure. As a result of wear, vibration and other factors, the supporting rod may move out of its place and not fall into the socket at the moment of closing. The door may not close or may close without the door closing sensor operating.

The problem can be solved this way: dismantle the hatch door and unscrew it around the perimeter. Open the hatch parts, install the hook base in place and assemble everything in reverse order.

Hatch door sagging

The door frame is usually made of plastic. All fasteners (hinges) are made of metal. Plastic is softer than metal, and over time it wears out and deforms at the point of contact. As a result, the hatch door may sag, and as a result, the lock hook does not go where it is supposed to when closing. In such a situation, it is necessary to replace either the entire door or the fastening parts. This can be done using the following algorithm:

Over time, the hatch door may sag

Broken door handle

The assembled lock mechanism consists of the following elements: handle, lock hook, lock rod, spring. Breakage of any part results in the door not locking or closing/opening.

According to statistics, the door handle most often fails, since it is subject to the most active influence from the user. To replace any of the listed parts, you need to disassemble the entire door and replace the handle.

The most common thing to break is the hatch door handle.

Removing the backlash

Backlash is a gap that, when the door is actively used, appears in the area where it is attached to the body.

To eliminate the gap, you need to remove the door and see what the problem is. In general, adjusting the hatch of an LG car is a simple matter. Now pay attention to the hinges: on top of them there are small plastic parts that look like coils. Inspect them for wear. As a rule, this is the main reason why backlashes form in the hatch door fastening.

Important! Finding these elements in a store in order to subsequently replace worn-out ones with new ones is extremely problematic. Therefore, for many years there has been a practice of replacing bushings with conventional FUM tape.

This is done extremely simply. Take a roll of tape and wrap it around each loop by eye: not a very thick layer, but not a very thin one either . Then put the door in place, but do not screw in the screws right away. Try opening and closing the hatch. If the gap is still visible, remove the door and add FUM-ki, then repeat the check. If the layer, on the contrary, turns out to be too thick, simply remove the excess.