When buying a washing machine, you can save money if you choose domestic models. For more than 20 years, this company has been successfully producing refrigerators and freezers, and since 2004 it began producing washing units.

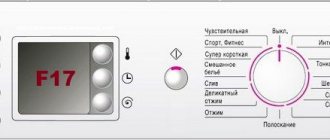

Modern models of Atlant washing machines are equipped with a special display on which information codes appear in the event of a malfunction

The latest technologies are used in the production of domestic equipment, so Atlant washing machines are practically in no way inferior to their foreign counterparts. All models are equipped with a modern self-diagnosis system, which allows you to quickly determine the cause of the malfunction.

Washing installations can have a full-fledged display with LED indication (models 50с81, 45у102, 50с102, 50с82, 45у82, 50у102), a small segment display (model 50у87), and also be without a display (models 35м101, 50у88). Cars that have a display on the dashboard, when a breakdown occurs, display an information code on it in the form of an alphabetic or alphanumeric combination. Models without a display transmit an error code using four indicator lights.

Manufacturers of washing machines do not recommend fixing any malfunctions yourself without first reading the operating instructions.

In our article we will list the main error codes for Atlant washing machines, tell you what they mean and how you can eliminate some of them yourself.

We are trying to fix the problem

To fix the “Sel” error on Atlant washing machines, you need to act consistently. First, we reboot the machine by disconnecting the machine from the electricity for 15-20 minutes. If a system failure was the culprit, then restarting will clear the error. Otherwise, we continue to look for the cause of the malfunction. The problem area is identified by checking a number of machine parts.

- Wiring, contacts and connectors connected to the dashboard from the control board. Carefully remove the top cover and visually assess the condition of the cords. If we detect a burning smell, darkened or damaged insulation, or loose terminals, replace the old one with a new one.

- Control board and selector. It is not possible to visually assess the performance of these elements. A thorough diagnosis is required, for which the parts must first be removed from the housing.

To assess the condition of the selector and board and begin repairs, you will have to take them out. We proceed like this:

disconnect the Atlant machine from electricity; pay attention to the powder receptacle, find a latch in the middle of the tray, by pressing which you can disconnect the dispenser from the body and remove it; release the bolts located behind the tray; remove the front panel.

It is recommended to photograph all the connectors and wires attached to the panel so that during reassembly you do not confuse their location. Next, remove the wiring, disconnect the bolts holding the module and take out the board. Similarly, we free the selector. Next, we replace all spare parts with new ones.

Prevention of the Atlant washing machine

In order for the Atlant machine to last as long as possible and not require any additional investments, it is necessary to operate it correctly and care for the device in accordance with the instructions.

Measures to prevent the appearance of error codes on the machine display are:

- Use high-quality washing powders (it is advisable to give preference to liquid detergents, since they are better washed out of machine parts).

- Every time after using the appliance, wipe the silicone door seal dry to prevent mold from appearing there.

- Use anti-scale protection products for your machine.

- Do not overload the drum with laundry.

Checking and replacing the interference filter

Atlant washing machines are equipped with a capacitor that protects equipment from power surges in the network. The noise filter copes only with small differences. Having felt a strong impulse, the capacitor will burn out, and in the worst case, the control module of the machine will also fail.

How to check the interference filter of an Atlant washing machine?

- Turn off the power to the machine.

- Unscrew the bolts securing the “top” of the washer and remove the cover.

- Find the capacitor, it is located on top.

- Inspect the power filter for swelling or carbon deposits.

- Remove the back panel of the case.

- Disconnect the wiring leading to the capacitor.

- Remove the surge protector from the machine.

- Place the multimeter probes on the element contacts.

- Measure the capacitor voltage at the input and output.

If there is no voltage at the output, the noise filter is no longer functioning. The device cannot be repaired; the capacitor will have to be replaced. If this is not the case, it is necessary to diagnose the control board.

How to fix it?

If you have problems with your automatic washing machine related to the electronics of the device itself, you must take the following actions:

- disconnect the device from the electrical network;

- unscrew the back cover of the device;

- remove the belt;

- carefully unscrew the bolts holding the engine and tachogenerator;

- remove the released parts from the car body;

- Carefully inspect the parts for damage, exposed contacts or disconnected wires.

If breakdowns are found, they should be eliminated - clean the contacts, replace the wires. If necessary, you need to replace the main parts - motor, brushes or relays.

In cases where errors arose due to problems with the water supply or drainage, the following steps must be taken:

- disconnect the device from the electrical network and turn off the water supply;

- check the inlet hose and water pressure in the line;

- check the drain hose for blockages;

- remove and clean the fill and drain filters;

- Reboot the device and reselect the required operating mode.

If these steps do not help, then you need to open the machine door, drain the water from it manually, empty the drum of things and check the operation and integrity of the heating element, as well as the serviceability of the pump.

When the machine does not work because the door is not closed, you need to try to close it again more tightly and check if there are any things stuck between the body of the device and its hatch. If this does not help, then you should check the integrity and serviceability of the locking lock and door handle. If they malfunction, they must be replaced in accordance with the recommendations from the instructions.

If excessive foam forms, you can correct the situation like this: drain the water from the automatic machine, select the rinse mode and, having removed all the things from it, rinse all the foam from the tank in the selected mode. Next time, add several times less detergent and use only what is recommended by the manufacturer.

If the device indication is faulty, then you need to check the degree of loading of the tank and the correctness of the selected mode. If this does not help, then you should look for the problem in the electronics.

And most importantly, if any error occurs, you must first reset the device program. To do this, disconnect it from the network and leave it to rest for 30 minutes.

Then the device is started again.

You can do this yourself, but if there is even one doubt that all the work will be done correctly, you need to call a specialist.

Some errors of the Atlant washing machine and ways to eliminate them can be found in the following video.

How to disassemble the SMA and remove the top cover?

Most breakdowns require removal of the top cover. To dismantle it, you need to twist 2 self-tapping screws located on the back of the device. Then the lid is moved to the side and lifted.

Further algorithm of actions:

- Remove the back wall by unscrewing the fasteners and removing the panel from the latches.

- Remove the top panel. To perform this step, remove the powder tray, unscrew the fasteners located underneath it, and disconnect the control panel. When disconnecting the module from the wires, you must be careful.

- Remove the drain filter, which is hidden behind a small door located at the bottom of the device.

- Remove the hatch. Together with it, the UBL and the cuff are removed, which is fixed with a clamp.

- Unscrew the pressure switch.

- Screw in the bolts holding the counterweights.

- Remove the belt, remove the motor and heating element located in the lower part of the MCA.

- Dismantle the tank by removing it from the shock absorbers.

- Twist the pump.

If it is necessary to disassemble the tank, it is unscrewed into two halves, gaining access to the drum, crosspiece and bearings. Read more here.

Causes

In order to get ahead of the severity of the problem and find ways to fix it, you first need to understand the reason for the occurrence of such an error.

Electronics related

Here it is necessary to immediately say that these problems, related directly to the electronics of the device itself or to problems connecting to the electrical network, are considered the most difficult and quite dangerous to solve. Therefore, you can eliminate them yourself only in cases where you already have similar experience and have the necessary tools at hand. Otherwise, it is better to seek help from specialists.

Such problems are indicated by the following codes.

- F2 – the sensor that determines the water heating temperature is faulty.

- F3 - there are problems in the operation of the main heating element. In this case, the device does not heat the water at all.

- F7 – errors with connecting to the electrical network. This could be voltage surges, too high/low voltage in the network.

- F9 – disturbances in engine operation, there are problems with the tachogenerator.

- F12 – problems with the motor, contacts or winding.

- F13 – an electrical circuit has broken somewhere. The wires could burn out or the contacts could break.

- F14 - a serious malfunction has occurred in the operation of the control module.

However, problems with electronics are not always the only cause of malfunctions in the washing machine.

With water supply and drainage

The following codes indicate such problems.

- F4 – water does not drain from the tank. This may be due to a clog in the drain hose, a faulty pump, or a clog in the filter itself.

- F5 – water does not fill the tank. It either enters the machine in very small volumes or does not enter at all.

- F8 – tank is full. Water either enters in too large quantities or does not drain at all.

- F15 – water leakage occurs. This error may appear for the following reasons: a break in the drain hose, the drain filter being too clogged, or due to a leak in the machine tank itself.

There are a number of other codes that also slow down the operation of the automatic machine.

Other

Such errors include the following.

- None – this error indicates that too much foam is forming inside the tank. This may occur due to a large amount of powder used, an incorrectly selected type, or due to an incorrectly selected washing mode.

- Sel – indication does not work. This error can also be classified as one that occurs due to electrical problems. But sometimes there may be another reason - tank overload, for example.

- Door – the door in the machine is not closed. This happens if the hatch is not closed completely, if something gets caught between the rubber bands of the door, or due to a broken locking lock.

When should the drain hose be replaced?

Sometimes situations arise that require replacing the drain hose. These include:

- the hose is short, it is not enough to connect to the sewer system;

- the hose is damaged: torn or cracked;

- a blockage has formed in the hose that cannot be removed using improvised means.

If you need to urgently complete the wash, the defect in the hose can be isolated. This is an emergency measure; in the future, the torn part will have to be replaced.

Let's decipher the code

Almost every Atlant washing machine has a fairly informative display, on which, in the event of a malfunction, one or another error is displayed, in our case error F4. But there are models of “home assistants” of this brand that do not have a display, but do have a self-diagnosis system. A natural question arises: how to recognize the F4 error if the machine simply has nowhere to display it?

This is not a completely correct question and here’s why. In this case, the Atlant machine generates an error using LED indicators located on the control panel. In particular, in our case, you need to look at the bottom row of light bulbs. The figure below shows the control panel of the Atlant washing machine without a display, on which the code F4 is displayed

Please note that the “on/off” light and the second LED in the bottom row are lit

No matter how the F4 code is displayed, its decoding is the same. Its essence boils down to the following: problems have arisen with draining waste water from the tank. A more extensive transcript shows us a list of reasons why this error appears. Let's look at this list in the next paragraph.

Why does this code appear?

The appearance of error F4 can be associated with various types of breakdowns, these include:

clogged drain system and in particular the drain filter or drain hose;

- pump malfunction, namely jamming of the impeller or malfunction of its electrical part;

- breakdown of electrical wires between the pump and the control module;

- control module failure (triac or resistor burnt out).

Eliminating the reasons for the appearance of the code

So, what this error means and the reasons for its occurrence are clear, all that remains is to figure out what to do in this situation and how to fix it. Start with the simplest thing, namely, unplug the machine and inspect the drain hose for kinks. If you moved the car the day before, it is quite possible that you accidentally bent the hose, so the water does not leave the tank.

Next, check the drain filter, which is located behind a special small door in the lower right corner. Unscrew the filter by placing rags under the machine or placing a low container under water. Rinse the part if necessary, and then return it to its place. This is where the simplest steps end, prepare the tools you will need: screwdrivers, pliers, multimeter. Now get started:

- disconnect the machine from the network, water and sewerage;

- drain the water from the tank, if necessary, through the hole under the filter;

- move the machine to a convenient place;

- turn the equipment over on its left side, you can place a rag or an old blanket under it;

- from the bottom you will see a pump, you need to disconnect the chip with wires from it;

- then unscrew the three screws holding the pump and remove it from the machine;

- install a new spare part and assemble the equipment.

If the washing machine gives error F4 not because of the pump, then take a multimeter and sequentially check the wires between the drain pump and the electronic module. Due to a broken wire, the pump does not start, and therefore water remains in the tank. The work is not difficult, but an ordinary user may not be able to complete it, keep in mind that this is an electrician's job.

Last on the list of faults is the electronic module, firstly, because its breakdown is not so frequent, and secondly, it is not easy to repair. To do this, you need special tools, a circuit diagram of the electronic module of your washing machine and minimal knowledge in the field of electronics. Let's give an example of a module from the 5521xx, 5522xx, 5523xx board series for the Atlant machine.

The 230V, 0.3A synchronous motor for the drain pump is connected to pins 1 and 2 of J2, circled in red in the picture above. The operation of the pump is monitored with a 0.8 A triac. It is these elements and their contacts that are checked first, and the module is also inspected for other damage; burnt-out elements that need to be replaced may be visually visible.

Thus, in the event of code F4 occurring, the Atlant washing machine can be repaired independently, because in most cases the cause is a faulty pump. You can replace this part yourself, but in other cases it is better to contact a specialist. Good luck!

https://youtube.com/watch?v=sE3IEVtXRfc

What can be done to ensure that breakdowns occur as rarely as possible?

A washing machine breakdown is an unpleasant situation, to put it mildly. No one wants to do laundry by hand or carry pounds of laundry to the laundromat. In order for your Atlant, an automatic washing machine, to work for a long time and not require the help of repair service employees, you should follow some simple rules for operating the equipment:

- Follow the rules for using the equipment described in the technical documentation supplied with the machine.

- If the washing machine runs all day, washing one load of laundry after another, you should take a break of 1-2 hours between washes.

- Carry out antifungal prophylaxis of internal surfaces, and, if necessary, treat affected areas with special means.

- Use high-quality laundry detergents, as well as special compositions for cleaning the washing machine and descaling. If the water is too hard, add softener to your laundry detergent every time you wash.

In the video below, the man talks in detail about how to independently fix most of the minor problems that periodically arise when operating a washing machine. After watching the video, you can not only clean the filter or powder compartment yourself, but also perform simple operations to replace electronics.

The times when domestically produced washing machines were inferior in quality to foreign analogues are a thing of the past. Modern Atlant machines with a built-in self-diagnosis system promptly inform the user about problems, allowing you to independently monitor the condition of the equipment.

Let's decipher the code

It is not difficult to understand what this code means. In the factory instructions, the combination “F6” stands for “failure of the reverse relay.” In simple words, the engine of the Atlant washing machine does not start.

From the technical side, a normal engine start looks like this:

- the user starts the machine by turning the selector and pressing “Start”;

- the control board gives the command to start the machine;

- the engine, or rather the relay coil, receives starting current;

- a magnetic field is formed, which gradually tightens the core;

- the core in turn drives the contact and closes the circuit;

- The motor winding is activated, the engine starts and gains speed.

If the engine does not start, then a failure occurred in the fourth step. The main reasons: overheating of the winding or damage to the relay contacts. Damaged electric brushes and peeled lamellas also cause problems.

Diagnostics will help to more accurately determine the nature of the malfunction. But before you start testing the engine, you should rule out an accidental “glitch” of the system. Therefore, we disconnect the power cord from the outlet, wait 15-20 minutes and repeat the startup. If the error is not reset, then you will have to identify the breakdown.

Error F6 in Atlant machines without a display

If your SMA does not have a screen, then you will know about error F6 by the flashing warning lights:

- in SoftControl models – “Water Hold” and “Rinse” will flash;

- in the OptimaControl series – “Rinse” and “Wash”.

Diagnosis and troubleshooting

What should be done to fix the problem? It is necessary to accurately identify the problem that caused the failure. Since there may be several options, you should check each of them, starting with simpler operations.

First of all, we comply with the safety requirements - disconnect the washing machine from the power supply. Only when the unit is completely de-energized is it possible to repair electrical devices.

To begin with, it is recommended to check whether the pressure level in the water supply system is sufficient, whether the valves on the taps built into the risers and at the entrance to the machine, directly in front of the intake hose, are fully open. After making sure that the water is flowing normally, you will have to carefully inspect the outside of the hose. It is probably twisted somewhere or crushed by the body of the washing machine.

It may seem to many that this is all elementary, but in practice it has been repeatedly proven that a third of the cases occur precisely in such situations.

The next step is to turn off the water supply to the unit and disconnect the water filling hose. The main task in this case is to make sure that there is nothing inside the hose. At the same time, the strainer installed on the inlet valve is checked. It is not difficult to find, since it is located at the point where the hose connects to the washing machine.

When your machine, after completed operations, continues to give an alarm signal in the form of F5 encoding, we begin to penetrate its body. To do this, unscrew and remove the cover of the machine. The intake valve is located in the upper left corner, near the rear panel. It is necessary to check it and all the pipes for clogging, then, using a multimeter, we make sure that the valve itself has not failed and check the functionality of its electrical circuit. It is quite possible that the device itself is working, but the wiring in a certain place is worn out, or the contacts are oxidized.

It would be a good idea to visually assess the condition of the wiring, since traces of carbon deposits and oxides are often visible to the naked eye. If the electrical circuit from the valve to the control unit is intact, and the valve itself is in working condition, you can move on to the next part - the sensor that controls the water level (pressostat).

One important clarification is needed here. If the machine does not pump water into itself at all, then there is no need to check the sensor.

And when water is poured into the tank and immediately drained, and a characteristic error light is displayed, you can immediately begin inspecting the machine with the level sensor. It is located near the back panel of the washing machine, in close proximity to the water intake valve, near the top cover.

The first step is to blow out and rinse all the tubes thoroughly, then check the electrical circuit with a multimeter. If the result is positive, there is only one thing left to do - look for the problem in the management module. But here you will have to think carefully about how prepared you are for such work. It is probably better to invite a competent specialist from the service center.

Elimination

The design of the Atlant washing machine is no different from the designs of models from other manufacturers. Therefore, getting to the complex elements of the device will not be difficult. When starting a renovation, evaluate its economic feasibility. And also follow the safety rules; carry out all work only with the equipment disconnected from the network.

The tachometer is faulty

To understand that the tachometer has failed, you first need to pay attention to how the unit works. The main “symptoms” of this malfunction:

- the rotation speed of the drum changes sharply;

- during the “spin” program, the drum rotates slowly, but should increase speed;

- during the “wash” program the revolutions are too frequent;

- After spinning, things remain wet.

To fix this problem, you first need to make sure that error F9 is caused by the tachogenerator.

- Unplug the washing machine.

- Remove the back cover of the device by unscrewing the fasteners.

- At the very bottom there is a motor that needs to be disconnected.

- After this, you need to disconnect the electrical wires from the tachometer and use a multimeter to check the voltage resistance value at the contacts. The indicator should be within 60 ohms. Then measure the voltage. When you crank the engine by hand, it increases and should be 0.2 V.

- If the sensor is faulty, it should be replaced. To do this, you need to loosen the harnesses and disconnect the wires. Unlock the latch, remove the protective cover and unscrew the fastening bolts. Remove the broken device and install a new device by performing these steps in reverse order.

The electric motor is damaged

To fix this problem, you need to remove the motor for inspection. You should disconnect the electrical wires from it, unscrew the bolts, and pull the engine itself towards you. First you need to check the condition of the brushes and mounting holders.

Brushes, an important element of moving contacts, begin to wear out after a certain period of time, which negatively affects the operation of the “heart” of the unit. Their wear can also generate error code F9. This is not difficult to determine: they will be too short. Worn brushes must be replaced.

If everything is in order with these items, you need to check the electric motor for current leakage to the housing using a multimeter. Each turn of the winding should be checked in case of breakdown. If all faults have been eliminated, but an error code is still issued, you should continue the diagnosis further.

Problems with the control module and electrical circuit

You should start by checking the electrical communication circuit. This element is located near the engine. It is a chip with wires. You should ring the multimeter several times for each transaction to eliminate possible errors. Replace faulty wires.

If everything is in order with the electrical network and there are no faults, there is a need to rule out an error in the control module. It is extremely difficult to fix this problem on your own. You will need certain knowledge and skills, since this is one of the main elements of any household appliance, complex in design, execution and operation.

This and other codes for the ATLANT washing machine are given below.

Warranty and service

The service life of ATLANT household appliances and washing machines in particular is 10 years. The manufacturing plant (Minsk) offers full warranty service for all ATLANT washing machines for 3 years. The manufacturer also provides a separate warranty for the electric motor of washing machines of the SMART ACTION/10 series - 5 years!

You can find the contacts of the nearest service centers in the supplement to the warranty card or on our website by clicking on the link. Please note that free repairs of equipment are carried out during the warranty period.

Motor test

It is better to entrust engine diagnostics to a professional repairman. However, you can figure out what to do and in what sequence on your own. The main thing is to first study the design of the motor and remember safety precautions. Our instructions will help you cope with the task.

Before starting the repair, let's remember how the engine works. Atlant washing machines are equipped with a commutator motor, which is compact and has higher power. The drive in this case is a belt drive - the engine and the drum shaft are connected by a belt through a pulley wheel. Inside, the part consists of several main parts: a rotor, a stator and electric brushes. There is also a tachogenerator that controls the acceleration speed.

To start checking the motor, you need to remove it from the machine, proceeding as follows:

- remove the back wall of the machine by unscrewing the corresponding screws;

- Rotating the pulley, unhook the drive belt;

- take a photograph of the position of the wiring connected to the engine;

- release the wires;

- loosen the bolts holding the engine;

- swing the part and pull it towards you.

Having taken out the engine, we place it on a dry, flat surface and begin checking. We connect the wiring from the stator and rotor windings, and then apply 220 V to them. Under voltage, the engine should begin to pick up speed. If this does not happen, then the motor is damaged and needs repair.

This method has its drawbacks. Firstly, it is impossible to test the operation of the motor in different modes. Secondly, connecting the engine directly is risky due to the possibility of a short circuit. Although, as a last resort, you can reduce the risks by including ballast in the circuit in the form of a heater. When leaking, the latter will begin to heat up, protecting the engine from fire. But supplying current is only the initial stage of diagnosis; then it is necessary to check other elements of the device, brushes, lamellas and windings.

Loud or unusual noise during wash or spin cycle

If your washing machine suddenly starts making loud noises or clanking noises during the wash cycle, you may have left coins, keys, or other foreign objects in your clothing pockets. If small metal objects from the drum fall into the tub, the washing machine may be seriously damaged. Therefore, it is important to check pockets before washing.

Another reason for unusual sounds may be a broken latch or door lock. The sound in this case will be buzzing and will stop when the door is closed.

If a squealing sound appears when washing at high speeds, this indicates that the drive belt is slipping. Tighten the belt or replace it with a new one

If you hear a rattling noise when the drum rotates, the drum bearing is broken and needs to be replaced.

How to check an electric motor?

An Atlant brand washing machine may indicate a malfunction with error F9 if there are problems with the electric motor. If there is a current leak to the housing, or the armature is broken, there is nothing you can do, the part cannot be repaired and you will have to replace the unit. And this part is expensive. Of course, theoretically the engine can be repaired. But this is not practical from an economic point of view. Such repairs will cost more than buying and replacing a broken part with a new one.

So, how do you determine that an engine replacement is needed? To do this, the motor must be removed. Disconnect the wires from it, unscrew the bolts and pull the motor towards you. Next you need to find the brushes, unscrew the holders and pull out these parts for inspection. If the brushes are worn out, they need to be replaced. You can tell if the brushes are worn out easily; they will be too short. By the way, always change brushes in pairs. And if: buy only original brushes, otherwise there is a risk of damaging the commutator lamellas and then the cost of repairs will increase significantly.

After this, we open the housing of the device and use the same multimeter to check for leakage on the housing, as well as the motor winding for breakdown. If there are no problems with the brushes or motor windings, and no leaks to the housing are detected, then everything is fine with the motor. We need to look for another reason.

How to fix it?

In order to find the exact cause of the appearance of such an error on the display and correctly eliminate it, it is necessary to carefully remove the motor itself from the device body. To do this, you must perform the following steps.

- Free up space around the machine so that the device can be placed on the floor and can be easily accessed from all sides.

- Using a screwdriver, you need to unscrew the back of the case, that is, the wall. Carefully remove the drive belt and set it aside.

- Release the chips from the drive and remove them along with all the wires. Using a screwdriver, remove the bolts that hold the motor to the housing.

- Remove the motor from the housing.

First of all, you need to carefully inspect the brushes. If indeed the reason for the error is their wear, then the problem can only be solved by completely replacing them. To do this, you need to purchase original brushes from a specialized store and install them in place of the old ones. Old elements are simply removed - their side parts are removed from the sinuses with light pressure.

If the triac fails, then you also need to go to the company store and purchase a new one. A burnt or even partially faulty triac is unsuitable for further operation. Here only its replacement is necessary.

If the cause of the error lies in a faulty wire contact, you must proceed as follows:

- carefully remove all terminals from the engine itself;

- conduct a visual inspection for burnt wires;

- clean all wires;

- If you find disconnected wiring, connect it in accordance with the diagram.

Error code F12 may appear on the device display at any time

However, simple precautions can help prevent this from happening:

- It is regularly necessary to clean the filters and pumps of the automatic washing machine from dirt and debris;

- It is necessary to promptly inspect and repair all spare parts of the device;

- If serious damage is detected, you must contact a specialized service center.

And one more thing: if you doubt that you can repair an automatic washing machine correctly and safely, it is best to seek help from a specialist.

See below for decoding codes for ATLANT washing machines.

The drum does not rotate

First, rule out the simplest reason - a broken door latch. If the lock is faulty, the drum will not rotate. To check, press the door button several times, it may be stuck.

If the drum in the washing machine is not mounted on a direct drive to the motor, but on a tension belt, the belt may come off. Move the engine down a little and adjust the belt tension tighter. Be careful not to overdo it. Too much belt tension will cause rapid bearing wear and failure. With the correct belt tension, when pressed, the belt moves about 12 mm. If your washing machine does not have a belt tensioner, the best alternative is to replace the belt with a new one.

Replacing the washing machine drive belt

Another possible reason for the drum stopping is a breakdown of the electric motor. In this case, you should contact a specialist.

Atlant error codes.

| CODE | CODE WITHOUT DISPLAY | PROBLEM | CAUSE AND REMEDY |

| SEL | Indicators do not light up | Control panel buttons are faulty. | We check: 1. the serviceability of the control buttons, they could be “stuck” due to dirt, grease, or pressed through, then they need to be replaced; 2.defective mode selector, replace if necessary; 3. indication board, change if necessary. 4.main board (electronic controller), repair or replace. |

| NONE | All indicators light up at the same time | Increased foaming in the tank. | 1.Use machine washable powder. 2.Reduce the powder dosage. |

| F2 | NTC temperature sensor faulty. | We check: 1. temperature sensor (the resistance of a working sensor is approximately 10 KOhm); 2.wiring and NTC connector. | |

| F3 | The heating element (heating element) is faulty. | The following is checked: 1. heating element (operating resistance is 25-30 Ohms); 2.wiring and connectors of the heating element; 3. heating element relay on the board. | |

| F4 | No drain. | We check: 1.passability of sewer pipes; 2. clean the drain hose and internal pipes; 3.clean the drain pump filter; 4. serviceability of the drain pump (the winding resistance of a working pump is approximately 170 Ohms), and also check its impeller (it may jam or fly off due to wear), if necessary, replace the pump; 5. If, when the drain mode is on, the pump does not receive voltage from the board (measured with a tester), check the wiring and the board. If necessary, we repair or replace the board. | |

| F5 | No bay. | You need to check: 1. whether there is water in the water supply; 2. is the tap open; 3.passability of the inlet hose, clean the filter, mesh of the hose and valve; 4.fill valve, if it needs to be replaced; 5. Is there power coming from the board? If not, then you need to check the wiring and the board. If necessary, we repair or replace the board. | |

| F6 | Engine reverse does not work. | Checking: 1.reverse relay on the control module, repair or replace the controller; 2. the drive motor is working properly, replace it. | |

| F7 | The voltage of the electrical network does not correspond to the normal value of 180-230 Volts. | We check: 1.voltage of the electrical network; 2.SMA power circuit; 3. serviceability of the control module. | |

| F8 | Water overflow (tank is full). | You need to check: 1.fill valve (possibly stuck open), replace it; 2. change the water level sensor (pressostat) and its wiring; 3. integrity of the pressure switch tube (may be clogged or leaking air), replace. | |

| F9 | The TAKH sensor (engine speed sensor) is faulty. | We check: 1. tacho sensor and its wiring, change it; 2.electronic controller, we repair, replace. | |

| F10 | Malfunction of the hatch locking device (UBL). | We check: 1. serviceability of the UBL and its wiring, connector; 2. Is there power coming from the module? If not, then the module needs to be checked and repaired. | |

| F11 or DOOR | The loading hatch is not closed. | 1. The hatch may not be closed tightly, close it tightly. 2.Inspect the door opening mechanism (the hook in the door may have broken). 3.Inspect the hatch hinges. Perhaps the hinges have weakened and the hatch is skewed, adjust. 4. Let's see if the UBL and wiring are working properly. 5.Look at the controller. | |

| F12 | The drum drive motor is faulty. | The following is checked: 1. the motor, its brushes, windings, wiring and connector; if necessary, we change the motor; 2. The control module is in good condition, is being repaired or replaced. | |

| F13 | The control board or its wiring is faulty. | The electronic controller and all wiring are checked and, if necessary, replaced. | |

| F14 | Software malfunction. | Memory flashing is required; if replacing the firmware is not possible, we change the module. | |

| F15 | Water leakage (the leakage sensor located in the pan has activated). | Checking: 1. the rubber of the hatch (carefully inspect the rubber, it could tear); 2. all connections inside the machine, pipes, tank, connection points of the inlet and drain hoses; 3.inner part of the powder loading tray; 4.drain pump filter. |

Our website contains many articles about repairing washing machines of other brands, which you can read here.

The troubleshooting methods described in this article assume that the performer has certain knowledge, skills and tools. Therefore, if you are not confident in your abilities, seek help from a repairman.

Determining faults by code

Atlant machines are equipped with a display that shows the selected operating mode, the amount of time remaining and the error code. The latter are of the following types:

- None;

- Door;

- from F2 to F15.

The appearance of one of these codes does not always indicate a malfunction. Knowing what a specific error means can help you narrow down your search for the problem. A specific code indicates the failure of a specific part. However, this only indicates problems with this element, although the fault may be hidden in other parts of the machine.

None

This signal indicates that due to the large amount of foam, the drum cannot rotate. If None appears frequently, it is recommended to replace the current washing powder with another one or select suitable operating modes.

Door

Door indicates that the machine door does not close. This problem occurs due to:

- door lock failure;

- damaged wiring supplying the central board;

- contact violations;

- improper installation of the washing machine;

- defective guide or clamp;

- skewed loops.

Some of these problems can be corrected yourself. To solve other problems, you will need specialized equipment to help assess the condition of the wiring.

F2

Code F2 indicates a failure of the temperature sensor, which occurs due to a violation of the integrity of the contacts (wiring) or a breakdown of the control unit.

F3

This error appears when the electronics of the washing machine detects a malfunction of the heating element. Failure of the heating element is caused by accumulated scale or broken contact.

F4

F4 appears if the water drainage is disrupted (water flows slowly away or stagnates in the tank). Basically, this code appears when the hoses become clogged or the pump fails.

F5

This signal indicates a blockage in the hose supplying water. Also, error F5 occurs if the inlet valve breaks.

F6

F6 appears on the washing machine screen if the reverse relay fails. This error also occurs in cases where the motor is faulty or the contacts are damaged.

F7

F7 reports insufficient voltage in the mains or a broken interference filter. In this case, it is impossible to restore the operation of the machine without the involvement of a specialist.

F8

Error F8 occurs if:

- the water inlet valve is jammed;

- the pressure switch is broken;

- The control board has failed.

Due to each such breakdown, water remains in the tank of the machine.

F9

F9 indicates a failed sensor that measures the engine speed. This malfunction also occurs due to broken contacts or broken wiring.

F12

This error appears when problems occur with the motor or control unit (triac on the central board).

F14

The appearance of this code indicates a software malfunction. The malfunction can be resolved by reinstalling the software.

Methods for solving some situations

Most of the errors that appear on the screen of the Atlant machine can only be eliminated with the help of specialized equipment. But in some cases, you can restore the functionality of the equipment yourself.

F3

Error F3 occurs if:

- The heating element is broken;

- scale has accumulated on the heating element;

- the control module has failed;

- The heating element is not connected correctly.

The procedure required to eliminate the malfunction is the same in each case.

Burnt out water heater

If you suspect a heating element failure, you must:

- remove the back cover of the washing machine;

- remove the terminals;

- unscrew the bolt in the center of the shank;

- Using a screwdriver, loosen the heating element and remove it from the socket.

It is impossible to independently determine whether the heating element is broken. Therefore, if there is a suspicion that the heating element has burned out, the part needs to be replaced. The new water heater is inserted according to the diagram above, but in reverse order.

Formation of scale deposits on parts

Scale on the heating element is considered the main reason for the failure of the heating element. To clean the part you will need specialized anti-lime products.

Control module failure

Depending on the type of Atlant washing machine model, the control module is located directly on the heating element (on new equipment) or nearby. This part is removed together with the heating element according to the above diagram. In the event of a breakdown, the control module is replaced with a new one.

See also

Rating of the 20 best freezers for the home and how to choose the right one

Incorrect device connection

This malfunction occurs in cases where the heating element was replaced. To fix the problem, you need to reconnect the contacts.

F4

Error F4 is considered the most common, as this code occurs due to a clogged water drain system. This problem is eliminated without the involvement of third-party specialists.

The drain filter is clogged with foreign objects

The drain filter is located at the bottom of the washing machine. To clean this part, simply unscrew the cap counterclockwise and rinse.

Sewer blockage

To identify this problem, just remove the drain hose from the pipe and turn on the spin mode on the machine. If the water drains and F4 does not appear on the screen, this indicates a clogged sewer.

Kink in the drain hose

Due to the bend, the water in the machine stagnates. To fix the problem, just straighten the hose.

Engine rotor wedge

Threads, toothpicks or other similar objects can penetrate the motor during the washing process and stop it. To eliminate this malfunction, you will need to disassemble the machine and clean the Atlas parts.

Drain pump failure

The drain pump breaks down due to the following reasons:

- the motor coil has broken;

- a short circuit has occurred (dark traces are visible);

- the impeller is faulty;

- the service life has expired;

- small objects hit.

In each of the above cases, the drain pump will need to be replaced.

Drain pipe clogged

Small objects often penetrate the drain pipe, interfering with the outflow of water. To eliminate error F4, you need to clean the clogged parts.

No power contacts

This malfunction can be identified by external inspection of the wiring. Additionally, it is recommended to check the condition of the wiring with appropriate equipment.

F5

Error F5 occurs if there is no water in the tank.

Clogged filter screens

Such meshes are located on the drain hose and filter. These parts are constantly in contact with water, which may contain both small and large particles.

To remove the blockage, simply clean the screens.

Lack of water in the water supply

If error F5 occurs, it is recommended to open the tap and check the availability of cold water before disassembling the machine.

Intake valve failure

Valve deformation is caused by frequent interruptions in the water supply. Failure of the electromagnet coil winding or core is also possible. This problem can be solved by replacing the valve.

No contacts on valve or solenoid module

If you suspect this problem, it is recommended to disconnect the terminals and clean the contacts. A faulty electronic module must be sent to a technician for repair.

See also

How to choose the right siphon for a sink, characteristics and operating tips

The pressure switch does not generate an “empty tank” signal

The main reason for this malfunction is a clogged hose going from the tank to the pressure switch. The malfunction can be eliminated by purging this element.

F9

Error code F9 indicates a malfunction of the tachometers that count engine speed. This problem occurs due to the breakdown of these parts or failure of the electronics.

Tachometer failure

The tachometer is located in the motor and consists of two elements: a stationary coil and a magnet. To check the first, you will need a multimeter that analyzes the resistance level.

Faulty coil

The faulty coil must be replaced. To identify a breakdown, you need to check the resistance level - first with the motor stopped (the indicator should be 150-200 kOhm), and then turn the shaft by hand. In this case, the indications should change.

Incorrect engine speed

This malfunction mainly occurs due to frequent overload of laundry or power surges. Both factors cause a short circuit in the motor windings, which requires replacing the failed motor with a new one.

F12

The appearance of F12 on the display indicates incorrect operation of the drum drive motor.

Poor contact on the wire block

This malfunction is detected by visual inspection of the wiring. To fix the motor, you will need to remove the terminals and clean the contacts. It is recommended to lay the wiring so that the cables do not come into contact with other parts during operation of the machine.

Broken windings

This problem occurs when the drum is constantly overloaded. A break in the windings is indicated by an increasing noise that occurs when the washing machine is running. This malfunction can be eliminated by replacing failed parts.

Brush wear

Due to the design features of Atlant washing machines, the brushes constantly rub, which leads to abrasion of parts. These elements must be replaced with new ones. During the procedure, it is recommended to check the condition of other engine components and clean the contacts.

Triac malfunction

The triac that controls the motor speed breaks down due to voltage surges or engine failure. This part must also be replaced.

What does this code mean?

After studying the relevant instructions, you can quickly come to the conclusion that error F14 means a breakdown of the control module of the Atlant washing machine, but in reality this is not always the case. The reasons for the error can be hidden much deeper, in particular, its occurrence can be affected by:

- clogged garbage filter;

- incorrect connection of the machine to the sewer;

- power surge.

Before reflashing or even changing the control module, you need to check the above reasons. Let's hope that we are talking about a banal short-term malfunction in the electronics of the Atlant washing machine.

Should I repair it myself or contact a professional?

Owners of an Atlant washing machine who are faced with breakdowns will have to make a decision: fix it on their own or turn to professionals for help. The warranty period of the equipment speaks in favor of the latter option.

The device is under warranty

If the free service period has not expired, then in case of any breakdown you need to contact a workshop . Self-repair will be grounds for refusal to fulfill warranty obligations.

The manufacturer is confident in the quality of its products, so the warranty period for Atlant washing machines is 3 years. To receive qualified assistance, you must contact branded service centers.

Advantages and disadvantages of repairing at home

Repairing equipment at home has a number of advantages, including:

- High speed of work completion. The specialist will be busy only with repairs, without being distracted by external factors.

- No need to buy tools. The master has them in stock.

- The employee travels to the address, so there is no need to pay for the transportation of equipment.

- Payment is made upon completion of work, after verification by the user.

- Affordable repair cost.

Among the disadvantages of home repairs are the risk of meeting with scammers, paying for the repairman’s travel, and the lack of warranty obligations (not all private repairmen provide them).

Pros and cons of repairs at a service center

Advantages of contacting a service center:

- the work will be performed on professional equipment, by specialists with specialized education;

- high-quality parts will be installed on the machine;

- A guarantee is given for the work performed.

Among the disadvantages of repairs at a service center:

- the need to deliver the machine to the addressee,

- long repair times,

- high cost of work.

To reduce these disadvantages to a minimum, you need to contact large workshops that are well known in every locality.

It's worth checking the fill valve

It was not possible to detect a breakdown, which means you need to check the inlet solenoid valve. It is located in the same place, under the top cover of the Atlant washing machine, only on the back wall, right behind the powder receiver box. First, disconnect the valve coil and check the contact resistance. In normal operating condition, the multimeter should show a resistance of 2-4 kOhm; if it shows much less or much more, it means that the inlet valve is faulty and needs to be replaced.

If the intake valve coil is in order, do not rush to rejoice. It is quite possible that the flow filter is clogged and is now preventing water from entering the machine. The solution to the problem is cleaning the flow filter. First, unscrew the inlet hose from the machine body. At the junction there is a small plastic mesh inside the fitting. This is a flow filter. Carefully remove it and wash it from dirt. If the mesh is overgrown with limescale, you can soak it in a solution of citric acid and then wash it.

In some cases, the cause of the F8 error is the electronics, specifically the control module. The Atlant firmware often fails, so you can call a technician who will reset it or replace it for you. In extreme cases, the control module will need to be replaced, but the master will decide this. When dealing with electronics, doing it yourself can be disastrous, so in any case, entrust this matter to a professional.