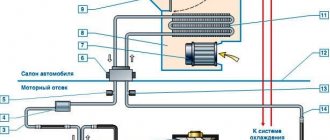

EGR valve — the main part of the exhaust gas recirculation system (Exhaust Gas Recirculation). USR task consists of reducing the level of formation of nitrogen oxides, which are a product of the activity of the engine. In order to reduce the temperature, some of the exhaust gases are sent back to the engine. The valves are installed on both gasoline and diesel engines, except those with a turbine.

From an environmental point of view, the system performs a positive function by limiting the production of harmful substances. However, the operation of the USR is often a source of numerous problems for motorists. The fact is that the EGR valve, as well as the intake manifold and working sensors, become covered with soot during system operation, which causes unstable engine operation. Therefore, many car owners resort not to cleaning or repair, but to shutting down the entire system.

Where is the EGR valve located?

The mentioned device is located directly on the engine of your car. In different models, the design and location may be different, however, you need to be guided by the location of the intake manifold . Usually there is a pipe coming from it. The valve can also be installed on the intake manifold, in the suction tract or on the throttle valve block. Eg:

The EGR valve on the Ford Transit VI (diesel) is located in the front of the engine, to the right of the oil dipstick

The EGR valve on the Chevrolet Lacetti is visible immediately when you open the hood; it is located behind the ignition module

The EGR valve on the Opel Astra G is located under the upper right corner of the engine protective cover

A few more examples:

EGR valve on BMW E38

EGR valve for Ford Focus

EGR valve for Opel Omega

Reasons for the formation of carbon deposits on valves

There are four main reasons why carbon deposits form on valve surfaces. Among them:

- Poor quality fuel . Unfortunately, in current conditions, gasoline or diesel fuel with various additives and that does not meet the proper specifications is often found at gas stations. During combustion, they form tar deposits on the valves. This also includes the use of low-quality and simply harmful fuel additives, which some motorists abuse.

- Wear of oil seals . The result of such a malfunction is oil on the valves. Carbon deposits from burnt engine oil settle on the surface of the valve and simply burn there.

- EGR system . Its main function is to burn exhaust gases. However, due to the design features of such motors, it is necessary to take into account that machines equipped with such elements are more susceptible to the formation of carbon deposits on the valves. This is why car owners often turn off the USR, but it is better to simply monitor the state of the system than to remove it.

- Natural process . Over time, carbon deposits form on the valves due to natural causes. Accordingly, with a high mileage of the car, especially if several different motor oils were used, then the formation of carbon deposits is inevitable. However, it is necessary to understand that it is impossible to bring it to a critical state and regularly use combustion chamber and valve cleaners.

What is an EGR valve and types of its designs

A certain amount of exhaust gases is sent through the EGR valve into the intake manifold. Next, they are mixed with air and fuel, after which they enter the engine cylinders along with the fuel mixture. The amount of gases is determined by a computer program embedded in the ECU. Sensors provide information for computer decision-making. Typically these are a coolant temperature sensor, an absolute pressure sensor, an air flow meter, a throttle position sensor, an intake manifold air temperature sensor, and others.

The EGR system and valve do not operate constantly. So, they are not used for:

- idle speed (on a warm engine);

- cold engine;

- fully open damper.

The first units used were pneumomechanical , that is, they were controlled using the vacuum of the intake manifold. However, over time they became electro-pneumatic (EURO 2 and EURO 3 standards) and fully electronic (EURO 4 and EURO 5 standards).

Types of USR valves

If your car has an electronic EGR system, it is controlled by the ECU. Digital EGR valves come in two styles - three or two ports. They open and close using operating solenoids. A device with three holes has seven levels of recirculation, a device with two has three levels. The most advanced valve is the one whose opening level is achieved using a stepper motor. It provides smooth regulation of gas flow. Some modern EGR systems are equipped with their own gas cooling unit. They can further reduce the level of waste nitrogen oxide.

Signs that your device is heavily soiled

The USR valve ensures proper circulation of exhaust gases and controls their amount returned to the intake manifold for final complete combustion.

There are certain signs of significant contamination, knowing which the driver can clean the unit in time and avoid car breakdown:

The first and main sign of contamination of the EGR valve is a violation of traction.- The car does not move well.

- The engine stops frequently.

- The idle speed fluctuates.

- While driving, jerks appear, the engine “troubles”, and detonation occurs.

- During acceleration, engine power decreases noticeably.

In cars running on diesel fuel, the USR valve must be cleaned of carbon deposits after every 100 thousand mileage. When using gasoline as fuel, such an operation is required after 150-200 thousand km.

The product of the functioning of a car engine is nitrogen oxides, an increase in the level of which leads to disruption of the operation of the main components of the car and environmental pollution. During operation, the valve itself and other components of the system (intake manifold, sensors) become covered with a layer of carbon deposits, and this negatively affects the operation of the engine and causes its breakdown. Timely cleaning of the EGR valve will help you avoid negative consequences.

The main causes of system malfunction and their consequences

Depressurization of the EGR valve is the most common malfunction of the EGR system. As a result, uncontrolled suction of air masses into the intake manifold occurs. If your car has an engine with an air flow meter, this can lead to a lean fuel mixture. And when the car has an air flow pressure sensor, the fuel mixture will be over-rich, which will cause the pressure on the intake manifold to increase. If the engine has both of the mentioned sensors, then at idle speed it will receive a too rich fuel mixture, and in other operating modes it will be lean.

Valve contamination is the second most common problem. We will discuss below what to do with it and how to clean it. Please note that the slightest malfunction in the engine can theoretically lead to a significant likelihood of contamination.

All malfunctions occur for one of the following reasons:

- too much exhaust gas passes through the valve;

- too little exhaust gas passes through it;

- The valve body has depressurized.

A malfunction of the exhaust gas recirculation system can be caused by failure of the following parts:

- external pipes for supplying exhaust gases;

- EGR valve;

- thermal valve connecting the vacuum source and the USR valve;

- solenoids that are controlled by the ECU;

- exhaust gas pressure converters.

Signs of a bad EGR valve

There are a number of signs that indicate that there are problems with the operation of the EGR valve. The main ones are:

- unstable engine operation at idle;

- frequent engine stops;

- misfires;

- the car moves jerkily;

- reduction of vacuum on the intake manifold and, as a consequence, engine operation on a rich fuel mixture;

- Often, if there is a serious malfunction in the operation of the exhaust gas recirculation valve, the car’s electronic system signals a check light.

During diagnostics, error codes such as:

- P1403 - malfunction of the exhaust gas recirculation valve;

- P0400 - exhaust gas recirculation system error;

- P0401 - ineffectiveness of the exhaust gas recirculation system;

- P0403 - broken wires inside the control valve of the exhaust gas recirculation system;

- P0404 - malfunction of the EGR control valve;

- P0171 - Fuel mixture is too lean.

Don't be so green: how to properly disable EGR

While bourgeois courts are dealing with bourgeois engineers who do not want to make the car sufficiently environmentally friendly, our fellow citizens are going in orderly ranks to services to turn off the exhaust gas recirculation system. Why is this happening? This is what we’ll talk about today: what EGR is, why it fails, and how to deal with it.

Give Peace a Chance!

John Lennon called for giving peace a chance, lying naked on his bed during his next protest. Environmentalists took this much more seriously, and in an attempt to give the world at least some chance of salvation, they force manufacturers to “strangle” car engines until they lose consciousness. The introduction of EGR (Exhaust Gas Recirculation) was supposed to reduce the content of nitrogen oxides NOx in the exhaust.

In general, this is the only task that the exhaust gas recirculation system solves. There are several versions of this system, but the principle of operation of EGR is always the same: a certain amount of exhaust gases flows through the valve back into the engine. This recirculation allows you to reduce the combustion temperature, especially in gasoline engines. And just high temperature is the condition for the appearance of nitrogen oxides.

EGR has no effect on anything else. This is a purely “ecological” feature of a modern engine. Unfortunately, its resource is quite limited, and a time comes when the system stops working as expected (more precisely, it stops altogether). And then excluding the entire system from engine control becomes a good way out of the situation. To be more convincing, let’s say that a working EGR does not work at high speeds or in emergency mode - under such conditions, the factory program of the control unit provides for its complete closure.

There is no need to be afraid of turning off EGR: the only unpleasant consequence will be an increased content of nitrogen oxides in the exhaust, but if you put some unknown nitrogen on one side of the scale, and trouble-free operation of the car on the other, then the second, of course, will outweigh. Because ecology is ecology, and nerves are more valuable.

How and why does EGR stop working?

There are several options for typical EGR breakdowns. These are valve jamming, breaks in the actuator circuit or valve position sensor, and unaccounted for air suction (or leakage). Within each option, several types of breakdowns can also be distinguished, so let’s take a closer look at each of these breakdowns separately.

The most common case is a jammed valve.

We all know very well that soot is formed when fuel burns. Over time, the amount of it deposited in the valve complicates its mobility. And the valve, naturally, jams. There are two options here: either it remains closed or open. It depends on your luck, and you will be luckier if the valve remains in the closed position. In this case, at least the soot does not enter the internal combustion engine. By the way, sometimes this method of turning off EGR is practiced - the valve is simply closed programmatically. Why this is not the best way - a little later.

The open position is bad primarily because all the combustion waste goes straight into the cylinders. If you look at how EGR works, you can see an interesting picture: in many engine operating modes, the valve is closed and does not take any part in the operation of the engine - for example, at high speeds and under heavy load. To put it very roughly, the closed position is more natural and does not cause any harm. Unless, of course, the EGR error makes changes to the operation of other systems that are associated with recirculation.

How to check the EGR valve?

When checking, it is necessary to inspect the condition of tubes , electrical wires, connectors and other components. If your machine has a pneumatic valve, you can use a vacuum pump to operate it. For detailed diagnostics, use electronic equipment that will allow you to obtain an error code. During such a check, you need to know the technical parameters of the valve in order to identify a discrepancy between the received and declared data.

The check is performed in the following sequence:

- Disconnect the vacuum hoses.

- Blow out the device, but no air should pass through it.

- Disconnect the connector from the solenoid valve.

- Using wires, supply power to the device from the battery.

- Blow out the valve, allowing air to pass through it.

When a check shows that the unit is not suitable for further operation, then purchasing and installing a new one is required, but quite often, it is advised to simply turn off the USR valve.

Selecting diesel egr cleaning products

Car owners complain that cleaning is of no use. But high-quality cleaning of components and assemblies is possible provided that the vehicle owner uses products specially produced for these purposes to perform operations. Do not forget: when cleaning the EGR system, do not use devices that scratch the surface of the parts. You don't even need to use a soft toothbrush. Only aerosol liquids are applied to the treated surfaces of the device.

- foam-forming carburetor cleaners;

- foaming agent in the form of a spray;

- USR, turbine, intake tract cleaner;

- carburetor flushing.

Carbon deposits are removed from the walls with a foam cleaner. The procedure is repeated up to 6 times. The number of repetitions depends on the thickness of the carbon layer. It is possible to keep the system operating stably by waiting for the moment when the dirt is removed from the action of the chemicals.

Carburetor flush is used as a means of soaking valve parts if they are significantly dirty. After soaking and pre-cleaning, you can use a spray. The product will help remove any remaining dirt.

How to turn off the EGR valve?

If there are problems with the operation of the EGR system or valve, then the simplest and cheapest solution is to turn it off.

It’s worth mentioning right away that chip tuning alone is not enough . That is, disabling valve control through the ECU does not solve all problems. This step only excludes system diagnostics, as a result of which the computer does not generate an error. However, the valve itself continues to operate. Therefore, in addition, it is necessary to mechanically exclude it from engine operation.

Some automakers include special valve plugs with the car. As a rule, this is a thick steel plate (up to 3 mm thick) shaped like the hole of the device. If you do not have such an original plug, you can make it yourself from metal of the appropriate thickness.

As a result of installing the plug, the temperature in the cylinders increases. And this threatens the risk of cracks in the cylinder head.

Next, remove the EGR valve. On some car models, this also requires removing the intake manifold. At the same time, clean its channels from dirt. Next, find the gasket that is installed at the valve mounting location. After this, replace it with the metal plug mentioned above. You can make it yourself or buy it at a car store.

During the assembly process, the standard gasket and the new plug are aligned at the mounting location. It is necessary to tighten the structure with bolts carefully, since factory plugs are often fragile. After this, do not forget to disconnect the vacuum hoses and put plugs in them. To complete the process, it is necessary to perform the mentioned chip tuning, that is, make adjustments to the ECU firmware so that the computer does not show an error.

How to turn off the EGR

We turn off the USR

What results will the jamming of the USR system have?

There are positive and negative sides. The positive ones include:

- soot does not accumulate in the collector;

- the dynamic characteristics of the car are increased;

- no need to change the EGR valve;

- Not as frequent oil changes.

Negative sides:

- if the engine has a catalyst, it will fail faster;

- the breakdown indicator on the dashboard is triggered (“check” light);

- possible increase in fuel consumption;

- increased wear of the valve group (rare).

Throttle valve

Another element of the car that is susceptible to very rapid contamination by soot, oil or dust is the throttle valve. The process of contamination of the throttle assembly is affected by the condition of the engine, the freshness of the air filter, and the operation of the recirculation system. Indeed, in most cases, exhaust gases are directed back into the cylinders through the throttle valve. Usually, contamination of the unit accumulates for quite a long time - at least 100,000 km, but if the EGR does not work correctly, the process of contamination of the throttle valve is greatly accelerated.

Symptoms of critical contamination of the throttle assembly are not very indicative: tripping, slow response to the gas pedal, errors in air supply, increased fuel consumption.

However, there is good news. The throttle body is fairly easy to open to clean. For this, there are special auto chemicals that wash away carbon deposits and oil deposits in a few minutes: for example, Throttle Cleaner from LAVR.

Cleaning the EGR valve

Often, you can restore the operation of the EGR system by simply cleaning the device. More often than others, owners of Opel, Chevrolet Lacetti, Nissan, and Peugeot cars face this problem.

The service life of various EGR systems is 70 - 100 thousand km.

When cleaning the EGR pneumatic valve, to clean the seat and rod from carbon deposits . When cleaning the USR with a control solenoid valve , as a rule, the filter is cleaned , protecting the vacuum system from contamination.

For cleaning you will need the following tools: open-end and socket wrenches, two carburetor cleaners (foam and spray), a Phillips screwdriver, and valve lapping paste.

Cleaning the EGR valve

After you have found where the EGR valve is located, you need to remove the terminals from the battery, as well as the connector from it. Next, using a wrench, unscrew the bolts that hold the valve in place, and then remove it. The insides of the device need to be soaked with carburetor wash.

You need to flush the channel in the manifold using a foam cleaner and a tube. The procedure must be performed within 5...10 minutes. And repeat it up to 5 times (depending on the level of contamination). At this time, the pre-soaked valve has become sour and is ready to be disassembled. To do this, unscrew the bolts and disassemble. Then, using a lapping paste, we grind the valve.

When the grinding is completed, it is necessary to thoroughly wash everything, both scale and paste. Next, you need to thoroughly dry and assemble everything. also worth checking the valve for leaks . This is done using kerosene, which is poured into one compartment. We wait for 5 minutes to ensure that the kerosene does not flow into another compartment, or that wet spots appear on the reverse side. If this happens, it means the valve is not sealed properly. To resolve the problem, you must repeat the procedure described above. Reassembling the system is performed in reverse order.

Choice of funds

Sometimes you can hear from car owners: “I’m cleaning and cleaning. But there’s no point…” High-quality cleaning of car components and assemblies is only possible if the vehicle owner uses specially created means to perform all operations.

It must be remembered that during the cleaning process you should not use devices that could scratch the surface of the parts. It is advisable to refuse even a soft toothbrush and apply only aerosol liquids to the dirty surfaces of the device.

The most effective are recognized:

Foam carburetor cleaners.- A similar product is in the form of a spray.

- USR, turbine and intake tract cleaner.

- Carburetor flushing.

Carbon deposits on the walls are removed using a foam cleaner. The procedure is repeated at least 5-6 times. The number of repetitions depends on the thickness of the soot layer. You can keep the system intact by waiting until the dirt dissolves under the influence of chemicals.

Carburetor flush is used as a means to soak valve components when contamination levels are high. After soaking and pre-cleaning, you can use a spray that will help get rid of the remaining small amount of dirt on the walls of the device.

Replacing the EGR valve

In some cases, in particular, when a valve fails, it is necessary to replace it. Naturally, for each car model this procedure will have its own characteristics due to the design, but in general terms the algorithm will be approximately the same.

However, immediately before replacement, you need to perform several operations, in particular those related to the ECU, resetting information so that the electronics “accepts” the new device and does not generate an error. So, you need to follow these steps:

- check the vacuum hoses of the exhaust gas recirculation system;

- check the functionality of the USR sensor and the entire system;

- check the patency of the gas recirculation line;

- replace the EGR sensor;

- clean the valve stem from carbon deposits;

- clear the fault code in the ECU and test the operation of the new device.

As for directly replacing the mentioned device, we will give an example of replacing it on a Volkswagen Passat B6. The work algorithm will be as follows:

- Disconnect the valve head position sensor connector.

- Loosen the clamps and remove the cooling hoses from the valve fittings.

- Unscrew the screws (two on each side) on the fastenings of the metal tubes intended for supplying and discharging gases from/to the EGR valve.

- The valve body is attached to the engine using a bracket using one power bolt and two M8 screws. Accordingly, you need to unscrew them, remove the old valve, install a new one in its place and tighten the screws back.

- Connect the valve to the ECU system, and then use software (it may vary) to adapt it.

As you can see, the procedure is not complicated, and as a rule, on all machines it does not present much difficulty. If you turn to a service station for help, the replacement procedure there currently costs about 4...5 thousand rubles, regardless of the brand of the car. As for the price of the EGR valve itself, it ranges from 1500...2000 rubles and even more (depending on the make of the car).

Procedure

First of all, it is necessary to determine the location of the valve to ensure that it is possible to clean the USR without removing the generator. To perform the valve cleaning procedure, you will need a set of tools, which includes:

open-end and ring wrenches;- screwdrivers (flat and Phillips);

- direct cleaning products;

- lapping paste.

To begin the task of cleaning the USR valve, you will need to remove the terminals from the battery, remove several bolts (most often there are 4 of them) using spanners. Disconnect the pipe by loosening the clamp (you will need a screwdriver). Now you can remove the valve itself.

Only by holding the valve itself in your hands can you visually determine the degree of contamination and decide which cleaning agent to use. For minor contamination, an engine or carburetor cleaner will help.

It is necessary to treat the unit with cleaner liberally. It is important to wait at least 5-10 minutes until the composition takes effect and the accumulated soot and soot dissolve.

You can determine how effective the selected cleaner is and whether the cleaning is done well by the movement of the valve piston. If, when pressed with a finger, it immediately returns to its original position, then you can be sure that the carbon deposits have been completely removed. Otherwise, the processing will have to be repeated.

Source

Signs of a diesel engine malfunction

The EGR valve is installed not only on gasoline, but also on diesel engines (including turbocharged ones). And the most interesting thing in this vein is that during the operation of the mentioned device, the problems described above for a gasoline engine are much more relevant for a diesel engine. First, you need to look at the differences in how the device operates on diesel engines. So, here the valve opens at idle, providing about 50% clean air in the intake manifold. As the number of revolutions increases, it closes and closes already at full engine load. When the engine is running in warm-up mode, the valve is also completely closed.

The problems are primarily related to the fact that the quality of domestic diesel fuel, to put it mildly, leaves much to be desired. During the operation of a diesel engine, the EGR valve itself, the intake manifold, and also the sensors installed in the system become contaminated. The consequence of this may be one or more of the following signs of “disease”:

- Unstable engine operation (jerks, floating speed at idle);

- loss of dynamic characteristics (accelerates poorly, shows low dynamics even in low gears);

- increased fuel consumption;

- power reduction;

- the engine will work more “hard” (after all, the EGR valve in diesel engines is precisely what is needed to soften the operation of the engine).

Naturally, the listed phenomena may be signs of other malfunctions, but it is still recommended to check the mentioned unit using computer diagnostics. And if necessary, clean, replace or simply plug it.

Another solution is to clean the intake manifold and the entire related system (including the intercooler). Due to low-quality diesel fuel, the entire system becomes significantly contaminated over time, so the described malfunctions may be the result of banal contamination, and will disappear after you carry out the appropriate cleaning. It is recommended to do this procedure at least once every two years, and preferably more often.

How is the USR usually washed and lubricated?

If you just throw it away, then yes, it works without problems.

But errors will pop up, which, however, do not affect performance in any way. I'm currently working in my free time on making a decoy so that errors don't pop up. There is no 100% option yet, but very little has been tried so far :) The fact is that the error pops up much less frequently, but it still happens. There are doubts about fuel consumption, because... The cartoon shows higher consumption in transitional modes, on the highway - as it was. But I haven’t made any real measurements yet, and Mult may be lying, because... it takes information from the brain, and the brain takes into account both the mass air flow sensor and the DBP when calculating the flow rate. According to surveys of those who have already jammed the USR, the consumption does not change, so for now I’ll watch. But my wheels are now larger in size than they were. Again, over 5,000 km of driving in Bulgaria and Romania, the average consumption was 11.23 l/100 km, which looks quite normal, considering that there were some mountains there and “high-speed” parts. And this consumption is real, based on columns and mileage. At the same time, I drove with a fake one instead of the USR. In short, work is underway :)

Broken, sorry: I think if problems arise, they will be similar.

In what frame? No, not like that. What cooler?!

We are talking about the USR cooler here, and you, apparently, are talking about the fuel cooler, which, yes, is located on the frame. And just try and see the EGR cooler.

Apakazhika? > And just try and see the EGR cooler.

Judging by the English forums, the Puma is a very good, reliable and long-lasting engine. So it’s a sin for you to blame him :).

Yeah, that was the case