Even the most expensive and high-quality automatic washing machine cannot boast of absolute noiselessness. During work, sounds will definitely be heard: a slight whistle, hum, creaking. A washing machine hums when washing - this is normal, but only if the nature of the sounds produced does not cause concern and the volume does not exceed acceptable values. An excessively loud roar of a rotating drum, accompanied by a crash and rumble, should certainly make the owner wary; these are most likely symptoms of a serious malfunction.

Noise standards

There is no such term as “buzzing loudly”; it is purely a subjective perception. The level of noise emitted by the machine is determined using special equipment. The maximum values should not exceed the values specified in the documentation; their values directly depend on the type of drive of the washing machine.

Direct drive washing machines can produce noise levels of 52-70 dB. For devices using belt transmission, the permissible values are slightly higher - 60-72 dB.

At home, it is unlikely that it will be possible to accurately measure noise levels, however, the threshold of the permissible value can be heard by ear. If the operation of the washing machine is perceived as background noise without causing discomfort, everything is fine. If the hum and crackling noises come to the fore during washing, drowning out other sounds, you should think about it. It is possible that the machine is faulty.

Tags

Washing machines the washing machine hums the work the machine produces the noise of the washing machine the noise of the washing machine is used that the machine makes noise the washing machine the washing machine hums Washing machines Why is the washing machine the hum of the washing machine existing washing machines the hum of the washing machine which the washing machine in the washing machine If the washing machine the drum of the washing machine a working washing machine the noise level from

masters of linen make a comment on the block of parts of the source data

Causes of noise

Excessive noise during operation of a washing machine can be caused by a number of reasons. In rare cases, this is a careless attitude towards technology, most often it is a sign of imminent failure of the device. Among the main reasons for high noise levels:

- incorrect installation of the machine;

- defective cuff of the loading hatch;

- foreign objects that have fallen inside the washing machine;

- wear of moving parts of the device;

- loose counterweights.

If you can correct mistakes made during installation yourself, then to solve other problems that create noise you will have to partially or completely disassemble the machine. It is up to the owner to do it himself or go to a workshop. In any case, before sounding the alarm, you should make sure that the machine is stable and that there is no excessive vibration during operation.

Precautionary measures

In order for the machine to work for a long time, you must adhere to certain rules.

- You need to be vigilant and carefully inspect things for small parts that may come off during washing and get into the tank. It is better to put such things in a special laundry bag.

- Remove money and other small items from your pockets that could damage the machine during the washing process.

- Protect the heating element from scale that forms from hard running water. To do this, you need to use water softening and descaling products.

- It is necessary to move the washing machine at least once every six months and check the serviceability of the hoses, as well as flexible wiring and pipes for damage.

- Wash and clean the drawer for powder and rinse aid. If this is not done, hardened powder particles may accumulate in the machine, which will interfere with the normal operation of the equipment.

- After each wash, leave the powder container and the machine door open. This is necessary so that the internal parts of the washer dry thoroughly.

All these recommendations will help extend the life of the washing machine and protect it from frequent breakdowns and calls to service centers.

Some types of repairs can be carried out independently, but still, if the breakdown is serious, it is best to contact a service center and call a specialist to your home.

Noise due to improper installation

If the washing machine makes noise on the first day after purchase, it is logical to assume that it was installed incorrectly. It is likely that to correct the situation, it is enough to simply level it by twisting the legs.

In order for the machine to work for a long time, not vibrate and not make unnecessary noise, during installation you need to pay attention to a number of significant points.

- Make sure that the transport bolts are unscrewed. Quite often, beginners who install the machine themselves simply forget about them.

- The floor on which the washing machine is installed must be level and durable. Do not operate the washing machine on a shaky, creaky floor.

- It is important to adjust the legs correctly. If necessary, you can use special anti-vibration inserts.

Even if the washing machine has been operating for some time, before you start looking for the cause of excessive noise inside it, it would be a good idea to make sure that it is stable and installed correctly.

Differences between direct and belt drive washers

Rotational motion can be transmitted from the motor to the drum shaft through a belt or electromagnetic system. LG owns a patent for Direct Drive technology, which is installed on most modern washing machines.

In a belt-driven SMA, the motor shaft is connected to the drum pulley using a narrow rubber belt. The intensity of rotation is controlled by the tachogenerator and motor brushes. Units with such a mechanism are usually noisier due to the large number of connecting elements.

In a direct drive SMA, the speed is set by an electromagnetic system, and the inverter motor rotates the drum without direct contact with it. This allows you to eliminate some breakdowns (for example, belt stretching, brush wear), increase the maximum speed and increase the tank load.

With identical technical characteristics, the inverter SMA promises to be quieter than the belt one. Due to the reliability of the direct drive, the risk of abnormal noise during spinning is also lower.

The belt drive also has an important advantage: if the weight is unevenly distributed in the tank, the rubber belt acts as an additional shock absorber. Direct drive mechanisms are more sensitive to uneven load distribution in the drum

Hatch cuff defect

Some may find it strange that the cuff of a washing machine can become a source of suspicious noises, but nevertheless, it is so. The purpose of the cuff is to prevent water from pouring into the gap between the body and the hatch during operation. If the cuff is installed correctly and the material from which it is made has not lost its elasticity, a small gap remains between it and the rotating parts. The cuff is not in contact with the drum. If it is distorted, the situation changes. The edges of the cuff go inward, preventing the normal rotation of the drum, thereby causing noise.

It is worth noting that such a malfunction, which creates an unpleasant noise, is more often found in inexpensive devices from little-known manufacturers; washing machines from LG, Samsung, Indezit and other world brands are free from this drawback.

If abrasions are visible on the cuff, this is the reason. You can correct the situation in the following way:

- open the hatch, turn the drum by hand;

- determine the part that clings to the cuff;

- stick a piece of fine sandpaper on the drum;

- run the washing machine in spin mode.

As the drum rotates, the sandpaper will remove excess rubber and friction should stop. Of course, this method will only work if the size of the protruding edge of the cuff does not exceed a few millimeters. Otherwise, the cuff will have to be replaced.

If the cuff is in order and the noise does not stop, you need to move on to checking other parts of the washing machine. Further actions involve disassembling the machine, completely or partially. Before getting down to business, you need to soberly assess your capabilities, and in case of the slightest doubt, contact specialists.

Why is the washing machine humming?

A huge range of washing equipment allows you to choose the model with the lowest noise level. Users have long been accustomed to the machine making a slight hum when drawing or draining liquid or during spinning. But if the device hums more than usual, this is a reason for diagnostics and troubleshooting.

Common causes of noise:

- The transport bolts have not been unscrewed . When connecting a new automatic washing machine (WMA), you must remove the bolts on the rear panel. These fasteners secure the drum to avoid damage during transportation.

- Installation problems . It is important to install equipment strictly according to level. Small distortions and uneven floors lead to increased vibration during operation.

- Blockage . If the drainage components are clogged: pipe, hose, filter, pump, the washing machine will hum, but will not drain the water. The cause of the blockage must be eliminated.

- A foreign object is stuck between the walls of the tank and the drum . Small parts may remain in the pockets of things, which penetrate into the holes and knock when rotated. The same goes for small rhinestones, beads, even bra wires can cause a similar problem.

- The pulley has become loose . The tank is attached to the pulley. When washing and rinsing, they may knock because the fastening is loose and the structure is loose.

- The bearing is worn out . If there is severe wear, you will hear the machine creaking when turned on and making a lot of noise. Some users say that the washer makes the sound of a jet plane taking off when in spin mode. The malfunction requires immediate intervention and repair.

- The counterweight bolts are unscrewed . Is SMA jumping on the spot? The point is in counterweights, which stabilize the work when the drum rotates. If their fastenings are loose, then the equipment will “wobble” from side to side.

- Drain pump malfunction . If the washing machine stops and does not drain water, it is worth checking the pump for serviceability.

- Worn motor brushes . The drum rotates with difficulty or does not rotate at all. This means that the graphite brushes have worn out or their contact with the engine has weakened.

- The hatch cuff is poorly installed . During normal installation, there is a gap between the rubber and the drum. If they touch, friction occurs and a hum is heard.

We have looked at the main problems, now let's begin to resolve them.

Loose Counterweight

The counterweight is a very simple device in the washing machine that can be the cause of the noise. Actually, this is a piece of concrete installed inside the washing machine. Its task is to dampen the inertia that arises during the rotation of the drum. Despite its apparent simplicity, it can become loose and, instead of calming the vibration of the car, bother its owner with creaks and noise.

The counterweight is easy to access - you just need to remove the top cover. Often, during operation, the mounting holes break, and the concrete block begins to “walk”, making a loud noise. If the counterweight moves freely, but the bolts cannot hold it because the holes are larger than the bolt heads, the counterweight will have to be replaced.

The transport bolts are not unscrewed

One of the most common reasons why a washing machine hums during spinning and washing. During assembly, at the factory, special bolts are attached to the washing machine body. Designed for fixing drum springs. It is because of them that the washing machine makes a lot of noise when spinning.

After delivering the machine to the installation site, the bolts must be removed. Otherwise, the movement of the drum damping springs becomes impossible.

Which in turn leads to loud noise.

You can remove the bolts yourself. Their location and quantity are indicated in each instruction manual. But it’s better to make sure that this is done when installing the machine in a permanent place.

Worn pulley or drive belt

If a belt-driven device is being considered, another reason why the washing machine is noisy during operation may be wear and tear on the rotation transmission system, namely: a loose pulley or worn out belt. To eliminate the noise in this case, you will have to partially disassemble the machine.

- The back cover is removed, it is held on by several bolts or screws.

- The big wheel just in the middle of the washing machine is the pulley. It must be carefully inspected, checked by hand for the presence of play. If the pulley “goes” there is nothing left to do but replace it.

- The belt is thrown over the pulley. It must be removed and inspected most carefully. In case of severe wear, signs of delamination, cracks, the belt is replaced.

It is also worth paying attention to the condition of the drum shaft. If the pulley has been poorly secured for a long time, wear may form on the shaft.

Tips for avoiding malfunctions

- Observe the permissible load during washing - leave the drum one third empty.

- Perform preventative cleaning between work cycles.

- Try to use programs with high water heating as little as possible.

- Open the door after each wash to allow the machine to dry.

- If you wash several times a day, take breaks of 30 minutes.

- Leaving the washing machine idle for a long time causes the lubricant to evaporate and dry out.

- For budget models, components quickly wear out or wear out.

- Follow the rules for transportation, installation and connection to communications.

Watch the video about why the washing machine is noisy

Noise due to worn drum bearings

Another common cause of extraneous noise is failure of the drum bearings. It’s easy to check their condition; you don’t even have to disassemble the washing machine. You just need to turn the drum several times by hand. If it moves freely and no extraneous noise is heard during rotation, the bearings are normal. If a characteristic crunch is heard, the drum resists rotation - the bearings must be replaced.

Basically, washing machine bearings fail and create noise due to the drying out of the oil seal, which ensures the tightness of the drum. Water gets inside the bearing, it rusts and wears out quickly and begins to create noise. Therefore, if the problem is caused by the bearing, you must immediately change the oil seal, otherwise you will soon have to disassemble the device again.

The degree of complexity of the bearing replacement procedure depends on the model and manufacturer of the washing machine. The procedure is different for machines manufactured by Samsung, Ariston, LG and others. Before getting down to work, it would be a good idea to study the disassembly instructions for a specific model and watch a video on the topic.

In general, work to eliminate noise is carried out in the following sequence:

- The top cover of the washing machine is removed.

- The dispenser is removed and the control panel is removed.

- The front panel is removed; as a rule, the bolts securing it are hidden under the cuff.

- The screws holding the back cover are unscrewed.

- The heating element is disconnected and removed.

- The engine is removed.

- The tank is removed.

Next you need to disassemble the tank. In most cases, it consists of two halves bolted together. Worn bearings are removed and others are pressed in. New bearings must be of the closed type, otherwise they will not come out for a long time. After this, the device is assembled in the reverse order.

How to remove strong noise when operating equipment

Replacing bearings

If the machine begins to make a lot of noise, the fault may be hidden in the bearings. Testing this hypothesis is quite simple - you need to turn the drum manually with the machine turned off. If the process went quietly, then you need to blame other broken parts. If your guesses are confirmed, you need to do the following.

- The front wall is removed (locking screws follow the cuff, the bottom panel and control panel are removed).

- The back wall is removed - you need to carefully unscrew the screws.

- The heating element behind which the engine is located is removed. It will also need to be pulled out, after first moving the belt.

- It is necessary to disconnect the tank, which is attached to the body using springs and shock absorbers.

- How to disassemble the tank? It usually consists of two halves bolted together.

- Worn bearings are knocked out and replaced with new ones.

- Everything goes backwards.

The process of replacing bearings for different brands is described in more detail in our articles about Samsung, Indesit, Ariston washing machines.

Foreign objects

The equipment can make a loud noise for another trivial reason - there is a foreign object in the drain pump. This is often indicated by the inconsistency of loud sounds heard during washing: they will resemble a crackling sound.

Foreign objects can be understood as bra underwires, coins, buttons and other small metal objects. Removing them will be easy:

- It is necessary to loosen the fastening of the heating element and pull it out.

- Using tweezers, objects caught in the pump are removed from the resulting hole.

- The heating element is put back into place, the rubber seal is lubricated with liquid detergent.

By the way, it is not recommended to replace and disassemble the drain pump without the help of a professional. But if the user is determined to do it himself, he will find this video useful:

The cuff is erased

The washing machine hums during the wash itself also because sometimes the sealing collar begins to rub too zealously against the drum. Rubber crumbs on the surface of the door will indicate this moment. You can try to figure out such a misunderstanding yourself (a method that is not always justified by experts):

- A piece of medium or fine sandpaper is fixed on the side of the drum using tape.

- The technique starts in push-up mode. This trick will cause the paper to strip the cuffs at the points of contact with the tank.

- The machine starts rinsing - this will clean the inside of the equipment from rubber dust.

Loose pulley

If the sounds are intermittent clicking sounds, then you may suspect a loose drum pulley. This is not surprising: gradually it can become loose. To prevent the part from freely moving, the loosened bolt is unscrewed and placed on a sealant, which will prevent it from loosening again.

How to secure a drum pulley

The counterweight is broken

The washing machine often makes a lot of noise due to the counterweights. These parts are needed to give stability to the tank during the squeezing process. Sufficient weight of such elements will perfectly balance the tank on both sides. What you need to know about counterweights? The difficulty is that such parts are located in hard-to-reach places. To examine them, you need to help yourself with a flashlight. And manual examination is also expected - after palpation, loose areas are tightened. In any case, if the integrity of the counterweights is compromised, they should be replaced to prevent destruction of the tank.

Worn brushes

The machine hums, but the drum does not turn - here you can suspect worn brushes in the electric motor. The knocking in such cases is usually very loud. It is best to entrust the work associated with this replacement to a specialist. This is due to the fact that the machine will have to be completely disassembled by removing the motor.

The user must understand: noise coming from the machine is a signal of a malfunction. Especially if this hum is abnormal. It is imperative to promptly diagnose and eliminate any problems that arise.

Noise due to problems with the electric motor

The next unit that can cause noise in a washing machine is the electric motor. The most common problem is worn brushes. In this case, the noise is especially loud, in addition to the hum, a characteristic smell is felt, the drum moves jerkily.

The procedure for replacing the brushes itself is not particularly difficult, but one must take into account the fact that you can only get to the motor by completely disassembling the device.

How to fix the problem yourself

Clean the drum

If the drum is not properly cared for, it becomes dirty, covered with limescale and rust. The main way to avoid dirt is to use water softener when washing. There are several ways to clean heavy stains:

- Cleaning with citric acid. Pour 200 g of the substance into the drum and start the washing cycle. In case of heavy contamination, repeat the cycle several times.

- Use of chlorine-containing substances (bleach, etc.). Advantages: high cleaning properties. Disadvantage: damage to rubber parts. Therefore, it can be used no more than once a year.

- Specialized cleaning products. They clean well from contaminants and do not destroy the parts and mechanisms of the device. The disadvantage is the high price.

Check transport fastenings and remove them if present.

Shipping bolts secure the tank when transporting the washing machine. They are removed before the first start. Technological holes for mounting bolts are placed on the rear panel evenly around the perimeter. There are usually 4 of them and they are clearly visible. They are unscrewed using a socket head or a wrench from the product kit. The fastening bolts are equipped with plastic bushings. Parts must be stored for use when transporting the device.

Check that the machine is installed correctly (using a level)

The position of the washing machine is adjusted by twisting legs and controlled by a level.

- Place a level on the top cover along the front wall.

- By adjusting the front legs, achieve zero level deviation from the horizontal.

- Place a level along the side panel. Adjust the height of the rear legs to achieve a horizontal level.

Adjust the hatch seal

Due to wear and tear, after improper installation, the door sealing lip begins to come into contact with the rotating drum. This may cause damage or leakage. Remedy:

- For replacement, use a cuff designed for a specific machine model.

- Loosen the clamp and remove the seal from the hatch.

- Unscrew the front panel, check the installation of the cuff on the tank - there should be no distortions, wrinkles, damage, etc.

- To eliminate defects, loosen the fastening clamp and install the seal correctly.

- Secure the clamp without overtightening it.

Check if the machine is overloaded with laundry

Overloading laundry leads to premature failure of the washing machine. If the machine is not equipped with an automatic laundry weighing function, you need to use the following rule. The drum cannot be filled more than 2/3 of the volume; the hand must freely penetrate into its upper part. For woolen fabrics the requirements are stricter: no more than 1/3 of the volume is filled.

Loud noise when draining water

A special case is that the washing machine works fine, but as soon as the water needs to be drained, it makes a lot of noise. The cause may be a dirty drain filter or a faulty pump. Before handling the pump, you should remove and clean the filter. If it is in order, you need to remove and check the pump.

In most cases, high noise levels during operation of the drain pump are caused by contamination of the impeller or difficult shaft rotation. If so, then it is enough to remove the pump, wash it and the housing, and it is quite possible that the volume of the machine will noticeably decrease.

Minor faults

Some washing machine models may squeak during washing.

This is how the equipment sends signals about a breakdown of the display unit. On most of them, a warning about a program error appears in the panel. This does not affect the quality of washing, but it does significantly affect the choice of programs. If the machine hums while draining, then it is worth checking whether it is draining water. Quite common reasons:

- Drain pump clogged or broken.

- The drain hose is clogged.

- The drain hose is kinked.

- The filter is clogged.

Cleaning the drain filter.

First you need to check the filter and drain pump. To do this, you need to unscrew the small door, pull out the filter, and clean it of accumulated debris. Free the pump blades from foreign objects. Before starting work, it is worth covering a piece of fabric, because water will flow out of the hole. After cleaning, all elements must be replaced.

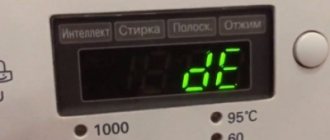

Modern machines themselves tell you what is wrong and display an error code on the screen. But this does not mean that you need to do the repairs yourself. This will require certain knowledge and skills. Disassembling the machine on the kitchen table using available tools will not always help to fix it. This can only complicate the work of the master. Therefore, if you are not confident in your abilities, it is better to entrust the assistant to a professional.

Noise caused by foreign objects

Often, small parts that get into it along with the laundry get stuck in the washing machine: buttons, coins, fastener parts. Sometimes they pass through the drain system and are caught by the drain filter, but this does not always happen. A small button can get into the space under the drum and get stuck between it and the heating element. In this case, if you spin the drum, you can hear a characteristic noise (creaking and crackling) at the bottom of the washing machine.

To eliminate noise in the washing machine, you need to partially disassemble the device, remove the heating element, tilt the machine, remove objects that have fallen under the drum using tweezers or a bent wire.

Extraneous noise during operation of the washing machine is not just an annoying little thing that irritates, it is a signal to the owner. If you hear a crackling sound or the noise becomes louder than usual, you shouldn’t think too long, you need to find the cause of the noise as quickly as possible and correct it. Doing it yourself or calling specialists is not so important; the main thing is to take action before the problem develops into a serious malfunction.

Drain filter clogged

The most common cause of loud noise when draining is a clogged drain filter. Most washing machines have a filter located at the bottom right. Some models have a lid that is easy to open by hand. In some models it is located behind a small panel that is secured with latches. You can remove it using a thin knife or screwdriver. To do this, you need to insert a tool into the slot and unfasten the latches. Next you need to check the drain filter.

- You need to put a thick rag under the machine so that the water does not spread when you pull out the filter.

- Unscrew the filter counterclockwise. If you can’t easily unscrew it, then you will have to pull it out along with the pump from the inside. It is better to entrust such manipulation to a master.

- If the filter is pulled out. You need to clean it with your hands from large debris.

- Use a soft brush and detergent to rinse the filter under running water.

- Inspect the filter hole with a flashlight. If there is debris there, clean that too.

- Put the filter back. Screw clockwise until it stops. There is no need to tighten too much to avoid stripping the threads.

- Next, we run a test washing program to check whether the hum has disappeared.

If, upon visual inspection of the filter, there was almost no debris in it, and a test run revealed that the hum did not stop, then most likely the cause of the noise when draining does not lie in the filter. And we need to look further.

Retaining springs squeak

The springs that fix the position of the tank may well be the source of the whistle. The rods can rub against the mounting sockets and make a very unpleasant whistle. Finding out whether this is actually the reason is quite simple: you need to remove the upper part of the washing machine body. Start the washing program and during operation (when a squeak appears) press firmly on the seat.

If the squeak disappears, then the problem is in the rods and springs. To eliminate the malfunction, it is necessary to lubricate the contact points with ordinary machine oil.

Faulty pump

If your machine begins to make a lot of noise when filling or draining water, then most likely the problem is in its pump. There may be three reasons. The first one is that the drain pipe is clogged. The issue can be resolved by cleaning it.

The second is that the filters are clogged. They are usually located on the front side of the machine, behind a special panel and are quite easy to clean.

The third reason is the most undesirable. If all the cleaning steps have been carried out, but the unit is still noisy during operation, then the problem is in the pump itself. You can finally verify this as follows.

For example, during the spin cycle, the LG makes a sound very similar to the operation of a transformer. In this case, replacing the washing machine drain pump cannot be avoided.