The service life of a washing machine depends on three main factors: brand, model, functionality. Various manufacturers claim the service life of their equipment in the range of 5-15 years. However, in practice, poor quality of water and electricity (voltage surges, sudden outages) leads to failures and breakdowns much faster. If it is quite easy to independently diagnose a mechanical failure: by vibration, knocking and other external manifestations, then in a situation where the washing machine does not turn on without any external reaction, it is much more difficult to determine the cause.

There are several main reasons why the washing machine does not turn on:

- There is no electricity in the household electrical network.

- Failure of the power cord.

- The “Power on” button is broken.

- Failure of the hatch locking device.

- Failure of the network filter.

- Malfunctions of internal wiring elements.

- Failure of the control module.

There is no electricity in the household electrical network

Let's simulate an unpleasant, but, unfortunately, typical situation. The drum is loaded, the powder is poured in, we insert the plug into the socket, but the automatic washing machine does not turn on, moreover, it does not react at all. First, it is necessary to exclude the influence of external factors, which are detected by the operation of a machine or RCD.

Electrolikbez!

For those who are not very versed in electromechanics, I will give a short explanation. A residual current device (RCD) is triggered if a leakage current occurs in the apartment's electrical network. That is, a terminal has become unscrewed in one of the electrical appliances, and the wiring supplies current to the housing. It is the RCD that protects the user from electric shock, and the wiring from overheating and fire. The machine (circuit breaker) disconnects the circuit in the event of a short circuit or overload. There is a third type - a differential switch that combines the functions of an RCD and an automatic circuit breaker.

Difavtomat

The first thing to do is unplug the washing machine from the socket. Then go to the apartment's electrical distribution panel and look at the position of the lever in the automatic machine. If necessary, move it from the “Off” position. (off) to “On” position (on). After turning on the difavtomat, we repeat the attempt to activate the socket, but using another device. For example, a table lamp. If the automatic circuit breaker works again, then the problem is in the socket. Its serviceability can be checked with an indicator screwdriver: the indicator should light only when in contact with one hole. When checking with a multimeter, the device is set to AC mode - ACV and the value is 220 V. The corresponding indicators should appear on the display. If the readings of the testing devices differ from the standard ones, then water has probably entered the outlet or the wires have burnt, and it needs to be replaced. If everything is fine with the socket, then the problem is in the washing machine.

IMPORTANT!

Do your own electrical wiring repairs only if you are 100% sure of the quality result. Otherwise, it is better to invite a specialist.

To start

First of all, you should check the basic reasons why the washing machine does not want to work, and only then move on to more complex diagnostics.

Check electricity

First of all, see if the machine is connected to the network. Even if the plug is inserted into the socket, check the serviceability of the plugs and the socket itself by plugging in, for example, a hair dryer or razor.

Is the plug or cord damaged?

Carefully inspect the electrical cord and plug for integrity, look for kinks, fractures, animal bites, traces of melting, burning and other damage. If the cord or plug is damaged, there is a risk of electric shock, so you need to replace the cord immediately. Until then, it is better to wrap the damaged area with electrical tape. However, this is only an imitation of safety; do not put off repairs.

Is there a water supply

Sometimes the wash cannot start because water does not enter the tank. First of all, check whether the liquid flows normally from the tap. With low pressure, the water will either take a long time to collect water or will not do so at all.

If the water supply is in order, you next need to check whether the water supply valve is open, the condition of the hose through which water enters the unit, and whether the manhole cover is tightly closed.

Another problem with the water supply may mean:

- The lock on the door (UBL) is broken.

- The filter mesh at the connection between the hose and the machine is clogged.

- The intake valve coil is burnt out.

- The water pressure sensor or programmer is broken. The pressure switch sends an incorrect signal to the control module, blocking the filling valve.

- The aquastop system may have worked.

- Full list of reasons in this article:

We fix 15 main problems with washing machines with our own hands

Failure of the power cord

Various wire defects are among the most common reasons that the washing machine does not turn on. The reason is that the wire is constantly deformed during operation: it is bent, pinched, stretched. It is not uncommon for it to be chewed by pets. Failure of a wire or plug is determined visually by the presence of significant thickening and discoloration of the insulation, mechanical damage, traces of melting, etc.

Burnt out socket

I strongly recommend replacing the wire completely, rather than repairing it with electrical tape. You need to buy a new wire with a solid plug. After removing the back panel of the washing machine, get to the connection point. In most modern models, the wires are connected to the washing machine using conventional terminal attachments. Before disconnecting the old wire, be sure to take a photo of the connection location so you don’t get confused with the wire markings later.

Power cord

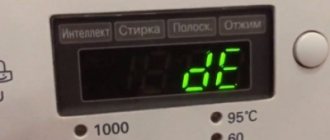

Most Common Error Codes

Error codes, their interpretation, causes and solutions are described in detail in the instructions supplied with the washing machine. Each brand has its own coding, recognition and reading system. Moreover, one manufacturer can equip its products with various algorithms for identifying the causes of malfunctions. Therefore, when unfamiliar symbols appear on the display or control panel, first of all, you need to turn to official sources of information - read the instructions or go to the official website of the washing machine manufacturer.

You can find and view the instructions for your washing machine online in the section: Instructions for washing machines.

The best option would be to contact qualified specialists or authorized service centers that have permission to service and repair household appliances of a particular brand.

The video shows a clear example of a Samsung washing machine failing. The technician explains in detail how the malfunction is detected and what you need to pay attention to during repair work:

Damage to the "Power" button

What to do if the indicators on the washing machine do not light up and it does not turn on. With a high degree of probability, the malfunction may lie in the “Power” button (Start, Start). This breakdown is typical for new models with push-button control. Checking the functionality of this button is done as follows:

- The washing machine is disconnected from the power supply.

- The top panel is removed: two screws from the self-tapping screw are unscrewed from the back and the cover is slightly pushed forward.

- The control panel is removed: the powder tray is pulled out, the screws that close it are unscrewed. The plastic latches bend and the panel rises slightly.

- The connection point of the “Power on” button is photographed and it is disconnected from the wires.

- The contacts are carefully connected directly, after which the washing machine is plugged into the outlet. If the power indicators light up and the washing machine starts executing the program, then the problem is in the button.

IMPORTANT!

When testing, it is necessary to completely eliminate the possibility of contact of the connected terminals with the machine body.

Power buttons

If the reason that the automatic washing machine does not turn on is the button, you do not need to immediately run out to buy a new one. There is a high probability of it sticking due to contamination. First you need to clean the inside surfaces of the button hole in the control panel. To do this, you need to completely remove the control panel and disconnect the board from the plastic facade. Naturally, the connection points of all wires must first be photographed. The plastic cover is cleaned using household chemicals. In this case, it is recommended to additionally clean the control board from dust and wipe the contacts with alcohol.

What to do to avoid problems

It is important to use your washing machine correctly. For this:

- Follow the instructions.

- Don't force your washer to wear out. If you wash several times a day, take breaks for a couple of hours.

- After washing, leave the hatch open and wipe the cuff from mold. Wash the dispenser tray periodically to remove any detergent residue.

- Read the ingredients of the detergents you use so as not to harm yourself and your car.

- Carry out scale prevention, including an empty machine at high temperatures. Use special tools.

By following simple rules, you can extend the life of your equipment.

Failure of the hatch locking device

If the power indicator on the washing machine is on, the control module allows you to select a washing program, but after activating it, an error message like “Error” appears on the display, then you need to check the functionality of the hatch locking device - UBL. It is a latch whose operating principle is based on the movement of a bimetallic plate. Long-term use and constant temperature changes can deform the plate and damage the device.

The first sign of a UBL malfunction is the absence of a click when closing the loading hatch door. For a deeper check, you need to partially disassemble the washing machine and disconnect the device. This is done as follows:

- The fixing clamp is removed from the hatch cuff.

- The cuff is bent from the UBL side.

- The two fixing bolts are unscrewed and the lock mechanism is removed from the inside.

- The wires are disconnected.

- The value is measured on the lock contacts with a multimeter.

If the UBL is faulty, then we replace it with a new one. The cost of such a part is quite low, and there is no particular need for repairs. If the blocker is working, then the reason for the failure of the washing machine may lie in the electronic control unit or command device.

UBL

There are cases of UBL failure during the washing process, or when the hatch door is closed. To unlock the door, you need to remove the top cover of the washing machine and press the door latch protruding from the hole on the back of the lock.

In some cases, the terminals of the connector connected to the blocker burn out. They need to be replaced, since a poor connection between the contacts quickly leads to repeated burnout of the device.

There is an indication

If, when you turn on the network and select a program, lights or symbols flash on the display, then in this case you need to figure out what the machine is not doing. First of all, pay attention to the door lock.

UBL

If the hatch opens freely during startup, the reason may be the following:

- UBL is faulty;

- wiring burned out;

- The control module is damaged.

A mechanical hatch locking device is checked using a specific method. This will be covered in another article. Pulse UBL can be diagnosed using an oscilloscope. We replace the faulty lock with a new one.

Hatch locking device

We check all wiring with a multimeter and repair damaged areas.

The module must be replaced and repaired by a good electronics engineer.

If the hatch is locked

If the hatch is locked and the wash does not start, then the following reasons are possible:

- the pressure switch is faulty or clogged;

- the pump is damaged;

- Fill valves do not work or are clogged.

If the level sensor is broken, the machine “thinks” that the tank is full and does not start washing. To solve the problem, it is necessary to replace the pressure switch. A similar situation may occur due to a clogged sensor tube. After cleaning, the machine will start working.

Before adding water, the module checks the serviceability of the pump. If it burns out, the wash cycle will not start. This is the logic behind the work. We replace the pump with a similar one.

The fill valves are burnt out, so the machine cannot start washing due to lack of water. We replace them with new ones, and also check the mesh for possible blockages.

Line filter failures

Each modern model of washing machine has a device such as an interference filter or surge protector. It is designed to smooth out electromagnetic pulses resulting from the operation of the electric motor and heating element. If the mains filter breaks, the washing machine does not turn on or off. In some cases, the network indicator may be on, but the programmer does not respond to commands. The second situation can also arise when the programmer (control module) or command device fails. But since these devices are quite expensive and difficult to repair, it is necessary to first exclude all other faults.

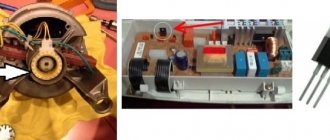

Diagnosis of a network filter malfunction is carried out as follows:

- The washing machine is disconnected from the power supply.

- The screws around the perimeter of the rear panel are unscrewed, after which the case cover and rear panel are removed.

- A multimeter is used to test the contacts of the interference filter in resistance measurement mode.

It should be noted that the interference filter cannot be repaired, and in the event of failure, only replacement is necessary. Purchasing new parts is not particularly difficult, since their characteristics are similar for entire model series.

Network filter

IMPORTANT!

In fact, the washing machine can operate without an interference filter. To do this, the contacts from the power cord are directly connected to the outgoing wires coming from the filter (as shown in the photo). But this method of “repair” can lead to dire consequences. The interference filter also protects the internal elements of the washing machine from external influences (voltage drops): control board, wiring, heating element, electric motor.

Replacing the filter is quite simple:

- The place where the wires are connected is photographed.

- The incoming wires from the power cord and the outgoing wires to the command device are removed.

- The bolts securing the element to the body of the washing machine are unscrewed.

- A new filter is installed, all terminals are connected to its connectors in the same order.

Causes of unit failure

Before throwing away the machine due to its malfunction, you can diagnose it yourself. Often the breakdowns in the product are minor, so parts are replaced without calling a technician.

The equipment may not start the washing program or even not turn on completely for several reasons. Their timely identification will extend the service life for several more years and save money.

No. 1 - lack of power supply in the network

In the case when the display does not light up when the power plug is plugged into the socket, and in products with a mechanical control type the device does not start at all, then there may be no current flowing.

The reason for this may be a malfunction in the electrical panel, failure of a circuit breaker, socket, or tripping of a protective shutdown in the presence of an RCD.

Breakage in the shield can occur due to long service life, voltage drops in the system, burnout or mechanical damage to the wire (for example, in the case of repair work), etc.

The machine, as a rule, knocks out when there is a short circuit, a sharp drop in current in the network, or water gets into the socket. To check its serviceability, you need to make sure that it is turned on correctly.

If the machine is knocked out, the lever will be in the lower position - off . If after switching on the device does not work, it means it has failed and will need to be completely replaced.

Characteristic signs of a protective device being knocked out are an electric shock to the user when trying to start the machine, after which the device turns on.

The RCD is triggered to prevent fires due to current leakage and to prevent electric shock to a person when the equipment is turned on.

Therefore, there may have been a power failure or the device may have malfunctioned due to poor quality. If this is the reason for the lack of electricity, then it is necessary to check its performance and the presence of related problems in the panel.

In another case, the equipment does not start when the outlet breaks down.

Externally, the device may look slightly burnt, with characteristic traces of black color in the plug connection holes, or melted

To check its serviceability, you need to use an indicator screwdriver and see if there is current in it. You can also try connecting another electrical appliance, such as a hair dryer, iron or table lamp. If the products work, then you need to look for another reason.

Using a multimeter, you can check the presence of phase in the socket in the following way:

- Take the meter and turn on the alternating current (ACV) measurement mode.

- Set the maximum value on the device – 220 V.

- Connect the probes of the device to the socket connectors.

- Record the network readings on a special display.

- Based on the information received, draw a conclusion whether the socket is working or requires further replacement.

When the above methods have been carried out and the cause has not been identified, then the functionality of the machine parts should be checked.

No. 2 - malfunction of the power cord elements

The wire of the product is constantly subjected to various deformations - bends, pinches, tension, and creases. Therefore, the possibility of damage during operation cannot be ruled out.

To determine this type of failure, it is necessary to visually inspect the cord, as well as the plug. The devices may show signs of burning or melting plastic and a corresponding unpleasant odor.

If such a problem is detected, use of the cord and plug is strictly prohibited as it may result in electric shock or short circuit.

You can also check if there are any breaks in the wire using a multimeter. In this case, the device will need to be connected to all three wires in turn. If a breakdown is detected, it is advisable to replace the cable rather than connecting the elements using electrical tape.

If the machine is connected to the network using an extension cord, then the reason for the lack of startup may be hidden in this device.

The functionality of the extension cord should also be checked by connecting other electrical appliances. If it malfunctions, the equipment will need to be connected through another device or directly into an outlet.

No. 3 - problems with the “Power” button

The wash may not start due to problems with the “Start” button. This problem most often occurs in newer generation of device models. The operating principle of such products is to directly supply current from the power cord to the button.

To check whether a part is working or not, you need to perform the following series of actions:

- disconnect the device from the power supply;

- remove the upper part of the product body;

- unscrew and remove the control panel on which the button is located;

- disconnect the wire connections from the button;

- connect a multimeter to them and check for the presence of current when the button mode is on.

If the button works, the device will produce a corresponding sound. If a problem is found, the part must be replaced.

The button may be dented due to prolonged use of the equipment, clogged with dust or washing powder, or may not work due to broken internal wires

Some equipment has a slightly different design principle, and the voltage is supplied not to the power button, but to the command device or electronic module. This depends on the model and manufacturer of the particular unit.

No. 4 - failure of the electronic module or programmer

The serviceability of these parts is checked only after the correct connection of all electrical circuits, the integrity of the wires, plugs, and the device that locks the hatch have been checked.

These unit components are quite expensive, so the feasibility of replacing them must be decided independently on an individual basis.

The reason for the failure of elements may be careless handling of equipment, a voltage drop in the network, moisture getting into the mechanism, or a defective new part.

To identify a breakdown, the command device must be disassembled. Their devices differ depending on the model and brand of the machine. The general disassembly procedure is the same, but the appearance of the part may vary.

No. 5 - the locking system does not function

If the equipment is turned on and the power indicator lights up and the washing program does not start, you should check the serviceability of such an element as the hatch lock.

As a rule, the machine locks the door when starting a program. If this does not happen, then you need to pay attention to this node.

In devices with a horizontal type of laundry loading, the door is locked using a special lock, which is located on the side of the hatch

To do this, disassemble the front part of the product body and measure the presence of voltage in this element with a tester. If the current passes, but the mechanism does not work, then it will need to be completely replaced.

If the device shows no voltage, then the control unit - the electronic module or command device - needs to be checked and repaired.

No. 6 - interference filter malfunction

Each model is equipped with a special element that is responsible for damping electromagnetic radiation during operation - an interference filter.

The part allows you to protect other equipment from electric waves that can damage it. If this unit breaks down, the machine will not turn on and the indicators will not light up.

The filter may break due to prolonged use of the product, a short circuit or a manufacturing defect. In the event of a breakdown, the electrical circuit is disrupted, therefore, voltage is not supplied to the control unit and the equipment does not work

In addition, the surge protector prevents the electronic internal system of the device from burning out or failing.

The more expensive the product and the more functionality it has, the more the components are susceptible to breakdowns in the event of voltage surges. There is a high probability that one of the important elements will burn out: board, motor, heating element, wiring.

Therefore, it is imperative to promptly replace the filter in the event of its failure in order to protect the device from more serious damage.

No. 7 - damage to internal wiring

Most devices have an internal structure in which the wires touch each other and, due to vibration, can intersect, twist, fall out of the electrical circuit sockets and break.

In the event of such a breakdown, the equipment will turn on, but the display with indicators will either light up, blink, or go out at the same time

To identify the area of breakage or burnout, it is necessary to completely disassemble the device. Careful examination of wiring and diagrams, as well as the use of a tester, will help identify problem areas. In the future, you will need to replace or solder the damaged areas.

Malfunctions of internal wiring elements

If, after turning on, the washing machine immediately turns off or does not perform one or more functions, then it is highly likely that damage to the internal wiring or control unit can be diagnosed. Breakage or burnout of internal wires, as a rule, occurs in budget models of washing machines from little-known Chinese manufacturers. Determining which wire has failed is quite difficult. Moreover, they may not burn out, but simply fall out of their sockets. To determine connection locations, you need to be able to read diagrams. To identify a burnt wire, you must have skills in working with a tester. In any case, to identify damage to the internal wiring, it is necessary to completely disassemble the washing machine body.

When turned on, all indicators react

You connected the washing machine to the network, it started, but suddenly all the lights turned on or began to blink chaotically. Signs such as these may indicate a wiring problem .

Only a qualified technician who is well versed in this issue should repair or change the wiring.

In such a case, you will have to either completely replace the wiring in the house, or repair the part that is causing the problem. The breakdown may be due to loose contacts , which can be easily repaired on your own. Also, blinking indicators sometimes indicate damage to the software module .

If, when you turn on the washing machine, all the indicators light up at the same time, this indicates problems with the contacts or wiring.

If the washing machine doesn't turn on the first time, there's no reason to panic. Perhaps the problem is not serious and you can solve it in a few minutes. If none of the proposed methods yielded results or you were unable to understand the intricacies of the repair, it is best to entrust the work to the service department.

Failure of the control module or command device

The selection and launch of the functions of the washing machine is carried out by an electronic module or a command device (programmer) in models with analog control. Diagnosis of malfunctions of these devices is carried out only after all other options have been excluded, and the washing machine turns off anyway. These are the most expensive components, which are also difficult to repair at home.

Control module

As for the control board, the maximum that can be done without an electronics engineer’s education and a special soldering station for microcircuits is to remove the device and carefully inspect it for physical damage and contamination of contacts, as well as swollen capacitors.

If, with sufficient experience and dexterity, you can try to re-solder the capacitors yourself, then a burnt-out microcircuit can only be replaced at a service center. However, in most cases, such repairs will be comparable in cost to ordering a new control board.

ADVICE!

The electronic module and programmer are quite expensive parts. Therefore, if you are not sure about their malfunction, it is recommended to send it to a service center for diagnostics.

Command apparatus

The command device is used on washing machine models with control knobs. To diagnose and repair it (or rather prevent it), perform the following steps:

- Remove the front control panel and the cover of the washing machine to gain access to the device.

- Disconnect the command device, having previously photographed the location of the connection wires.

- Completely disassemble the device. By pressing the plastic latches on the sides of the case, you can remove the cover and disconnect the board.

- Inspect the board thoroughly and if you find burnt tracks, solder them.

- Clean all contacts and measure their resistance with a multimeter.

- Disconnect the center gear from the core.

- Thoroughly clean the nest from dust, treat the gears with alcohol and reassemble in reverse order.

IMPORTANT! For most modern models of washing machines, if analog control is combined with a large number of functions, the programmer is too complex and cannot be repaired.

Checking the serviceability of the socket

There are often situations when the machine does not start the washing cycle because the socket is broken.

The easiest way to check the functionality of the power supply is with an indicator screwdriver. If such a measuring device is not at hand, you can connect other electrical equipment to it (for example, a light bulb or a mobile phone charger). If the power supply connector is working properly, but the washing machine still refuses to start washing, the reason should be looked for in the device itself; for this you will need a multimeter. See also -

Atlant washing machine displays error F3 - what does it mean?

Interference filter (FPS): meaning and performance check

The control module, electric motor and other parts create radio frequency waves when the washing machine is running, which can harm other household appliances located near the machine. To protect electrical devices, the machine is equipped with an interference filter. If it malfunctions, it will create an obstacle to the passage of electric current. This will be the reason why the automatic machine does not start the washing process. To check the functionality of this part, you need to diagnose the wires at the input and output, as well as the device itself using a tester. If the FPS does not work, you need to order a new filter from the service center or make a request for its replacement.

The Indesit washing machine does not turn on, the indicators do not light up

After making sure that the cord of the Indesit washing machine is fixed and inserted into the power supply, you can start looking for the problem if there is no backlight on the work panel.

The most common of these is a breakdown of the varistor or the power button. It can be corrected by replacing it with a new spare part.

The indicators do not light up for another reason: if the element responsible for the process burns out on the control chip. The control board is called to detect a breakdown. The failed part is replaced with a new one. The process is labor-intensive, so it is better to contact a workshop.

Power button does not respond

Sometimes the machine refuses to turn on precisely because the power button is damaged or stuck. Often the contacts simply oxidize and it stops responding to pressure. This assumption is checked immediately after diagnosing the power cord and interference filter.

To remove the button, you will have to remove the cover of the machine body. Next, the wires are pulled off the key; it is better to photograph the connection diagram - this will help when reinstalling the part. Then you need to pry the latches and pull out the button.

First, the removed button is probed with a multimeter. Then the resistance it produces is checked. If a problem is identified, the part will have to be replaced. Sometimes the problem can be solved by cleaning the contacts, so technicians recommend trying this option. Even if after this the key does not ring, you will have to replace it.