Published: 12 Nov 2020

An automatic washing machine requires a minimum of attention: load laundry, select a program, turn it on, and after washing, take out clean items. But sometimes things go wrong and unusual situations happen. One of them is when the washing machine does not spin after rinsing.

The SMA may turn off immediately after rinsing or after an unsuccessful attempt to spin the drum during the spin cycle. Sometimes the washing machine goes into spin mode and spins the drum at low speed without accelerating. As a result, things just hang around inside and remain wet.

From the experience of the masters! If your SMA is stuck with water in the tank and does not rinse or spin, then see the article Why the washing machine does not drain the water. This malfunction is associated with drainage problems, not spinning problems.

In this article we will consider the case when the washing machine cannot spin, that is, the drum does not accelerate after the machine has drained the water normally.

Wrong choice of washing program

If the machine stops spinning clothes, pay attention to what washing mode is set. There are a number of programs where this function is not provided at all. For example, spinning is not carried out when washing silk or wool. To fix the problem, just change the mode to the desired one.

Pressing the “Cancel Spin” button

Some models of automatic washing machines have a special button that allows you to completely disable the spin function. It’s not difficult to find: there is a crossed out spiral drawn on it. You or someone in your household may have pressed it accidentally. To solve the problem, simply press this button and the spin function will be restored.

Incorrect spin speed setting

In addition to automatic programs, washing machines have special controls that allow you to control the settings. One of these is the lever or button for setting the number of revolutions. Look, maybe your regulator is turned to o. If this is indeed the case, then to fix the problem, set it to the required number of revolutions.

The spin does not work: when the washing machine is working

Situations when the washing machine stops spinning are not necessarily associated with a breakdown. SMA sometimes stops after draining due to simple reasons that you can easily deal with without the help of a specialist. On working equipment, the spin mode does not work when:

- There is an overload of laundry. The instructions for each washing program indicate the maximum weight of laundry that can be loaded, with the recommendation not to overload the machine. There is also a table showing the weight of different types of clothing or things. If you mixed up the maximum weight for different programs and loaded more things, the washer may not be able to spin. Take out some of the things and run the spin cycle again.

- There is an imbalance in the distribution of things in the drum. The washing machine stops spinning not only because of excess weight. It does not tolerate unbalance well and does not spin out things that it cannot distribute evenly throughout the drum, for example, one pillow. For balance, it is recommended to add some other things, but so as not to overload the machine with weight. The drum doesn't pick up speed and when things get lumpy. This often happens when washing bed linen. Smaller laundry gets into the duvet cover, and the washing machine drum spins at low speeds or the spin stops after several attempts to spin the drum. Load the CMA evenly so that things balance each other and don’t clump together.

- No spin mode selected. Delicate washing for delicate fabrics, silk, wool or other items takes place without spinning, or the washing machine specifically rotates the drum at low speeds. Full information on the programs is in the manual.

If you used a gentle wash before regular washing and did not change the program, the machine will spin poorly or not at all. Turn on the additional spin program. Next time, pay attention to the selected program. Many SMAs remember the previous one and work on it until you change your choice.

Have you checked the load, imbalance and selected program, but cannot understand why the spin mode in the automatic machine does not work? Most likely, the cause is a breakdown and you need a technician to identify it and fix it.

Error in the distribution of laundry in the drum

Any automatic washing machine distributes the laundry around the drum in a certain way before spinning. This is a necessary condition that allows not only to perform a high-quality spin, but also to avoid shaking during the washing process.

If the laundry cannot be distributed, for example, it has formed a lump or the item is light and alone, the program may not allow spinning. At the same time, an error code appears on the display of some models. You can solve the problem manually. To do this, drain the water, open the hatch and untangle the laundry, distributing it evenly. After this, set the spin program.

During the spin process, squeaks and knocking noises are heard

Sometimes you can encounter such a breakdown - a knocking sound that appears during the operation of the SMA or directly during spinning. This happens when small foreign objects that were previously in your pockets get into the space formed by the washing machine drum and its tank. To remove them, you will have to pull out the water heating element.

If you neglect such moments, the consequences can become unpredictable, up to the complete jamming of the washing machine.

The machine may also creak due to worn bearings and the drive belt. In each case, you will have to disassemble the unit and inspect the specified elements.

Exceeding the range of motion inside the tank

Modern models of washing machines are programmed to detect the amplitude of vibrations of the laundry inside the tank during spinning. If the level of fluctuations exceeds the permissible norm, the device simply stops spinning the laundry. There may be several reasons for exceeding the amplitude of oscillations.

Incorrect installation of the washing machine

This often happens when the machine is installed on an uneven floor or an obstacle gets under the leg. To solve the problem, you need to adjust the legs of the device, preferably using a level. Use special pads or rubber mats to keep the machine stable.

Failure of shock absorbers

The task of shock absorbers in a washing machine is to dampen vibrations in the tank. The reason for premature wear of shock absorbers can be washing large masses of laundry, which during the spin cycle are constantly lumped together, creating an imbalance. As a result, the machine begins to jump, and the spin quality decreases significantly. If the shock absorbers do not work at all, then in this case the spin mode may not turn on. Replacing the shock absorbers will help solve the problem. In this case, it is best to seek professional help.

If the wash is finished, there are no errors on the display, but the laundry is wet

In this case there are several reasons:

- The speed is set to low (from 800 to 1000). Some device models cannot produce high-quality spins at low settings.

- Underweight. When washing one or more small items, spinning is difficult. It is recommended to fill the drum at least half of its required weight.

- Washing bulky laundry. When placing bedding in the bin, it often clumps or gets tangled during the spin cycle, so it remains damp.

Presence of blockages in the system

If there is a blockage, the device may completely refuse not only to spin the laundry, but also to drain the water. The blockage can be natural or mechanical. Mechanical occurs as a result of various small objects entering the drain system, for example, coins, buttons and other things.

To fix the problem, it is recommended to clean the drain system filters. In modern models, the drain system is located on the front part at the bottom of the device. To get to it, you need to open a special lid or hatch, after which you should unscrew the filter installed under it. It is necessary to unscrew counterclockwise. Carefully inspect the filter; if there is dirt, remove it.

Important! The blockage may not be in the washing machine itself, but in the sewer system to which the device is connected. Thus, if it was not possible to restore the spin function after cleaning the filter, try cleaning the sewer system or drain hose.

How to clean the drain filter

Cleaning the filter should be done in stages. The procedure requires the following steps:

- Turn off the water supply and disconnect the equipment from the power supply. This is necessary for safety reasons so as not to receive an electric shock.

- Open the hatch cover under which the filter is located. In some models, the filter is located under the false panel at the bottom of the case.

- Drain the remaining water from the tank. It is important to be prepared that water may start to pour out, so you should take a basin or a rag.

- Unscrew and remove the catch filter.

- Remove large debris and foreign objects from the filter. Having removed the main dirt, all that remains is to clean the filter with a regular sponge with a hard surface, and then rinse under high water pressure.

- Secure the filter to its original position. The part should be positioned evenly, without distortions.

Malfunction of the drain pump (pump)

Very often, a clogged pump simply burns out as a result of an excessive increase in load. You will not be able to fix this problem on your own. To restore the functionality of the equipment, you will have to buy a new pump and replace it.

Important! To avoid costly repairs, always check your items' pockets before washing. You can also use special covers and bags to reduce the risk of clogging during the washing process.

Failure of the pressure switch (water level sensor)

A pressure switch is a special sensor that determines the water level in the washing machine and also controls its quantity. It is possible to understand that the problem is in the pressure switch by the following signs:

- The wash cycle has already begun, but water is not being collected;

- During washing, the machine picks up too much or, conversely, too little liquid;

- Water remains in the drum even after the wash cycle has completed. As a result, the laundry remains wet. Unfortunately, in the event of a serious breakdown, it is impossible to repair the pressure switch at home. This part is calibrated at the factory. However, you can replace the spare part yourself by purchasing the required one in the store. To do this you need:

- unscrew the top panel and carefully remove the cover - the sensor is located at the top of the washing machine on the side;

- disconnect the pressure switch by unscrewing the bolts and disconnecting the tube and contacts;

- connect the new device and assemble everything in reverse order.

More detailed information is in the article: Water level sensor in a washing machine repair and replacement

After this, you need to check the device by running a washing cycle on the machine. If you do everything correctly, the problem will be fixed.

Reasons for lack of spinning and their elimination

The washing machine has a simple design, but parts often wear out and fail. As a result, a number of breakdowns can occur when the equipment stops performing the functions inherent in its electronic system.

One of the main problems that may arise during operation is poor-quality spinning or its complete absence. Even owners of brand new washing machines can encounter the problem of lack of spin. Let's look at the possible reasons in more detail.

No. 1 - washing clothes without twisting

Modern machine models are equipped with a large number of options and innovative technologies that allow you to remove washed items from the drum completely dry or, conversely, wet.

The versatility of modern washing machines ensures gentle care for delicate fabrics: some of the laundry is washed with a spin cycle, and some without it.

If you discover that things have not gone through the twisting procedure, you need to check the “no spin” button. It is possible that the no-twist function was accidentally turned on when selecting a program.

No. 2 - imbalance of loaded laundry in the drum

Expensive washing machines have more functions and capabilities for economical and efficient washing. One of the additional functions is the distribution of loaded items inside the drum, which helps prevent things from bunching up into a single lump.

In the absence of such a function, washing machines may malfunction during the execution of a running program.

To eliminate the imbalance, you need to stop it and distribute things evenly. Then you can start the spin function

No. 3 - problem with the drain pump

In this case, the spinning process occurs, but the waste water is not poured into the sewer. Thus, things remain wet after twisting. To correct the breakdown, it is necessary to replace the pump (pump).

To replace the pump, you will need to perform several manipulations to disassemble the machine, prepare the necessary tools and spare parts in advance

Let's look at how to replace the pump in machines from Samsung, Whirpool, LG, Ariston , etc.

To do this you need:

- Disconnect equipment from all sources: power, water supply and drainage.

- Place the product body in a side position.

- Detach the bottom to gain access to the pump.

- Unscrew the screws and pull out the pump by pressing it from the side of the drain valve.

- Disconnect the wires from the pump.

- Remove the clamps and drain the remaining water into a prepared container.

After this, it is necessary to disassemble the pump, remove and clean the volute (if it is suitable), and replace the pump. At the end, you should reassemble all the parts in reverse order.

No. 4 - malfunction or wear of the pressure switch

The spinning mode may not turn on if the water inlet and outlet sensor is broken.

During normal operation, the machine receives a signal about the presence of water in the tank, about the need to turn on the spin cycle or drain the water

If the wrong signal is given, then the spin will not turn on and the sensor will need to be replaced.

No. 5 - malfunctions in the control system

The electronic or mechanical control system may malfunction after sudden changes in electrical power, due to the long service life of the equipment, or failure of the stabilizer.

If the washing machine does not spin for an unknown reason, then the tachometer, which is responsible for the number of revolutions made, or other sensors may be broken

A breakdown of the speed control sensor is quite rare, but if it occurs, the machine performs a poor-quality spin. In this case, you will need to reflash the control system or replace the board.

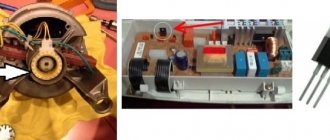

No. 6 - failure of the electric motor

If the motor breaks down, the spin function in the product does not turn on at all. The cause of engine failure may be a malfunction of the windings, their breaks, wear of the lamellas or brushes. To repair this unit, you will need to disassemble the washing machine, remove and inspect the motor.

How to determine engine failure:

- if the engine sparks during inspection, then urgent replacement of the brushes is necessary;

- in the presence of strong noise and overheating of the equipment, the cause may be a violation of the integrity of the winding;

- Peeling of the lamellas and the appearance of burrs on them can also lead to the appearance of sparks.

The lamellas must be checked during disassembly at the same time as the graphite brushes.

Failures are eliminated in the following order:

- It is necessary to turn off the machine - disconnect the drains, water pipes and the electrical network.

- Disassemble the product body: remove the back panel and straps.

- Remove all bolts that secure the engine.

- Disconnect the terminals and wiring that connect to other components.

- If the tank prevents free access to the engine, you need to lift it slightly.

- Different models have different structures from each other, so you will need to remove the side walls of the machine to successfully remove the engine.

Next, you should replace the broken parts or tighten their fastenings for normal operation.

This is what the engine looks like after a major or partial overhaul and complete assembly. If the engine cannot be repaired, you will have to order a new one

After the manipulations have been performed, you should install the repaired motor, assemble the washing machine in the correct sequence and check its operation.

No. 7 - clogged sewer drain

If the reason is not a breakdown of parts or a malfunction of the electronic control system, then the waste water drain pipes into the sewer may be clogged.

To check for debris, you need to disconnect the hose from the sewer outlet, place it in a bucket or other container and turn on the twist/spin function (marked in the figure)

You may need to clean the pipe with a cable. If a breakdown is found, then the machine will work correctly, and the stagnant debris will come out of the tube.

No. 8 - debris in the drainage device

If the spin function in the washing machine does not work or any malfunctions occur during the process of starting the procedure for unscrewing things, you need to check for the presence of foreign objects in the drain element.

The part is located at the bottom of the machine. It is recommended to clean the drain filter at least twice a year. If any problems are detected in the operation of the equipment, cleaning should be carried out immediately.

Clean the device carefully and thoroughly, removing all foreign objects.

If you detect malfunctions in the washing machine related to the spin function, it is recommended to immediately diagnose the product.

Please note if:

- the equipment has stopped twisting clothes well (remains wet);

- water remains in the tank even after turning on the pump;

- The spin cycle is quite noisy.

It is also recommended to regularly clean the washing machine, all components and filters to prevent possible damage or clogging.

Bearing failure

The drum of any model of washing machine rotates due to the bearing. If the bearing seal becomes unusable, a number of problems arise due to moisture getting there. Including the spin function is disrupted. You can understand that the problem of failure lies in the bearing by the following signs:

- The washing process is accompanied by extraneous sounds. This may be a hum, crunching, crackling or metallic grinding sound.

- During spinning or working at high speeds, an uncharacteristic whistle is heard.

- The car begins to jump strongly, the amplitude of rotation of the tank increases.

- The drum begins to wobble a lot (play).

- The quality of laundry spinning deteriorates.

If the cause of the failure lies in a faulty bearing, it is necessary to replace it in a timely manner. Otherwise, operating a faulty machine will lead to more serious problems. To replace a bearing, you must follow the following algorithm:

- Be sure to disconnect the device from the power supply and turn off the water supply tap.

- After this, unscrew the back and top panels. Then carefully remove the control module and dispenser.

- Remove the heating element and other parts that prevent you from reaching the motor.

- Remove the motor and pull out the drum.

- Then remove the tank and take out the bearing. To do this, you will have to make an effort. Use a hammer and screwdriver.

- Install a new oil seal and reassemble the machine.

Prevention

Regular maintenance helps reduce the risk of malfunction. For reliability, it is worth using a set of measures.

Checking pockets before washing

Foreign objects often become clogged in the filter, causing the spin function to turn off. Pre-checking your clothing pockets will eliminate the need to frequently clean the filter.

Washing powder quality

Poor quality powder negatively affects the condition of internal mechanisms. Using proven powders, you will be able to save on equipment repairs.

Network filters

Using a surge protector protects the washing machine from sudden power surges and short circuits. The surge protector turns on automatically and does not consume a large amount of resources.

Periodic cleaning of the machine

By periodically cleaning the filter and drum, you will be able to get rid of accumulated dirt in a timely manner. The ability to carry out cleaning yourself simplifies the maintenance of the machine.

Broken lock on the hatch

Sometimes the washing machine may start the washing process, but after a while it stops. The cause of the malfunction may be a failure of the hatch locking device. Repairing it yourself is labor-intensive and requires special skills and knowledge. To fix the problem, it is best to replace the UBL (hatch blocking device) with a new one.

Preventive measures

The best option for extending the life of your machine is to prevent the unpleasant consequences of sudden breakdowns. It is recommended not to stop caring for the unit at the end of the next washing process. This procedure is not difficult and does not require much time either:

- Remove the tray for washing powders and rinse it thoroughly under hot water;

- rinse the niche intended for the dispenser, wipe it dry;

- wipe the rubber cuff around the loading hatch to prevent all kinds of debris from accumulating on it in the form of threads, powder residues, etc.;

- Do not immediately close the door tightly - the drum of the machine and its other internal parts must dry well;

- Do not wash the inner walls of the drum with abrasive compounds.

A good housewife, who cares about her assistant, organizes a wet cleaning of the room and its ventilation after each wash. In addition, it is necessary to inspect the washer for leaks, even minor ones, because they will still turn into major problems.

Incorrect motor operation

If your model of washing machine is with direct drive, for example: LG “Direct Drive”, then the reason is most often a malfunction of the speed reading sensor (tacho sensor); if the part is faulty, the start of the washing process is accompanied by an unpleasant ringing metallic grinding sound or sharp short-term shocks of the drum. This part is located at the rear of the device, directly on the motor. If it fails, it is replaced with a similar new one.

On asynchronous engines with a belt drive, at the rear of the engine on the shaft, there is also a tacho sensor, which can often fail. This part is visually and structurally different from the direct drive sensor. Failure to reach full speed can also cause wear on the carbon brushes.

Tachometer failure

The tachometer will inevitably break if you run the wash all the time with an overloaded machine. Thus, she has to work at maximum speed. This sensor is designed to monitor the number of revolutions made.

If it fails, then the rotation of the drum is not controlled and the speed may not be set correctly. It is worth noting that the tachometer fails for one more reason: the connection of contacts and wires is broken, and its fastening is also loose.

If the sensor itself is faulty, it should certainly be replaced. And if the wiring is broken or the fastening is loose, then the screws must be tightened, and the wires must be cleaned and insulated.

The location of the tachometer is the same in almost all models. But, it is worth studying the instructions, for example, for a washing machine and determining where it is located.

Control module is faulty

This reason is rare, but a breakdown of the control unit cannot be ruled out. The control board contains microcircuits that control the operation of each part and program in the washing machine.

It is difficult to diagnose a malfunction in the module, so the control unit is inspected last. We list the most common problems:

- The tracks on the board are damaged (burnt out), power failure

- Failure of the seven-meter is directly related to engine operation

- Failure of the relay that supplies power to individual components of the machine

Malfunction of the heating element of the heating element

Due to constant contact with hard water, scale forms on the heating element, the amount of which increases each time after washing. Over time, breakdowns form on the metal shell and voltage surges occur. As a result of such surges, the control module may signal a shutdown. As a result, the machine may turn off just at the spin stage or an error may appear on the display. You can clean and inspect the heating element yourself, but it is not always possible to detect a malfunction visually; it is better to use a multimeter.

Important! To avoid damage to the heating element, it is necessary to clean it from time to time using special products. If your water is too hard, you can use special additives during washing.

If you cannot find out the reason for the lack of spin on your own, you need to seek professional help from a service center or a private repairman. The technician will be able to carry out high-quality diagnostics, thereby detecting the problem that has arisen and eliminating it in the shortest possible time.