- How to lubricate a computer fan

- How to lubricate a stove motor

- How to clean a cooler

Most computers have three fans. One is located in the power supply, the second is in the computer case, and the third is in the central processor.

A fan malfunction can be detected by noise.

Fans are needed to cool the system. If at least one of the fans stops working, the system may overheat and some information may disappear.

Your first instinct may be to replace the cooler. But this is most often not necessary. You can simply lubricate a faulty fan, and all it takes is one drop of oil.

How to choose oil

The wrong choice of oil for the fan can lead to complete failure. Many people use WD-40, a special lubricant developed by an American company to lubricate all kinds of noisy and squeaky surfaces. But you should not use this product on your computer fan.

It only helps if you lubricate an object that rarely moves, for example, a door hinge. But the fan is in constant motion and spins at high speed.

It is better to use household lubricating oil designed for sewing machines, power tools, door locks, and hinges. There is a special oil for sewing machines. It is light and viscous, can withstand high temperatures and is specially designed to lubricate parts operating at high speeds.

Fan operating principle

Most fans are supported by journal bearings, which consist of a shaft that rotates inside a cylinder or sleeve.

The cylinder consists of porous metal lubricated with oil. When the shaft begins to rotate, some of the oil from the bushing moves closer to the shaft, creating an oil film. This way the metal parts hardly touch, are not damaged, and the noise is almost inaudible.

Ideally, there is always enough oil inside the cylinder and the fan does not wear out. But at some production costs, for example, if the bearing is poorly glued, some of the oil evaporates. Then the fan will start to work slower, its parts will begin to rub against each other and wear out, and the computer will overheat. There will be noise.

In this case, you should add one drop of oil into the cooler.

What to make a split plastic washer from Where to find a replacement rubber ring

I received a letter by email in which site visitor Vasily shared his experience in repairing coolers. I liked his advice, I believe that they will be useful to many who are faced with cooler repair.

I often have to repair coolers and decided to share my experience:

✔ If a split plastic washer is lost or broken, it can be made from a plastic travel ticket card; the main thing is to choose a card of suitable thickness. Business cards made from the same material will also work.

✔ If a rubber ring crumbles, breaks or is lost, a gas lighter can serve as its donor. There is a rubber ring of suitable size under the valve. Different models of lighters have different ring thicknesses, so you need to choose the right one. If you come across a ring that is thicker than necessary, then it needs to be installed on the bottom of the impeller axis, and under the fixing washer, put what was previously on the impeller axis from below.

How to lubricate a fan

To lubricate the fan, you need to disassemble the computer and remove the cooler from it. Place the fan on the table and carefully remove the sticker. Part of the sticker is located just above the wiring gap. From here it is easier to bend it.

Remove the rubber plug from the middle of the fan. To do this, you can use a small screwdriver, carefully placing it behind the edge of the plug.

You will see the end of the shaft inside the cylinder in the resulting depression. Place one drop of oil into the indentation.

Just one drop is enough, no need to pour oil into the bearing.

Return the rubber stopper to its place and cover it with a sticker on top. Sometimes the sticker stops sticking. Then you can use regular electrical tape.

After the fan has returned to its place, the computer must run for several minutes before the oil completely lubricates the cooler. After some time, the computer will become quieter and stop getting too hot.

- How to lubricate a computer fan

- How to lubricate a stove motor

- How to clean a cooler

Most computers have three fans. One is located in the power supply, the second is in the computer case, and the third is in the central processor.

A fan malfunction can be detected by noise.

Fans are needed to cool the system. If at least one of the fans stops working, the system may overheat and some information may disappear.

Your first instinct may be to replace the cooler. But this is most often not necessary. You can simply lubricate a faulty fan, and all it takes is one drop of oil.

conclusions

This is how you can lubricate the cooler in your computer with oil yourself, without turning to specialists. Dismantling and installing a fan is a simple matter and does not require special skills or deep knowledge in electrical engineering and information technology.

If you find an error, please select a piece of text and press Ctrl+Enter.

Related posts:

No related photos.

Rate this article:

( 4 ratings, average: 3.00 out of 5)

Tweet Pin It

about the author

alex_bert

One answer

- Alexey 03/09/2021 Reply

Thank you very much!

How to choose oil

The wrong choice of oil for the fan can lead to complete failure. Many people use WD-40, a special lubricant developed by an American company to lubricate all kinds of noisy and squeaky surfaces. But you should not use this product on your computer fan.

It only helps if you lubricate an object that rarely moves, for example, a door hinge. But the fan is in constant motion and spins at high speed.

It is better to use household lubricating oil designed for sewing machines, power tools, door locks, and hinges. There is a special oil for sewing machines. It is light and viscous, can withstand high temperatures and is specially designed to lubricate parts operating at high speeds.

Fan operating principle

Most fans are supported by journal bearings, which consist of a shaft that rotates inside a cylinder or sleeve.

The cylinder consists of porous metal lubricated with oil. When the shaft begins to rotate, some of the oil from the bushing moves closer to the shaft, creating an oil film. This way the metal parts hardly touch, are not damaged, and the noise is almost inaudible.

Ideally, there is always enough oil inside the cylinder and the fan does not wear out. But at some production costs, for example, if the bearing is poorly glued, some of the oil evaporates. Then the fan will start to work slower, its parts will begin to rub against each other and wear out, and the computer will overheat. There will be noise.

In this case, you should add one drop of oil into the cooler.

How to lubricate a fan

To lubricate the fan, you need to disassemble the computer and remove the cooler from it. Place the fan on the table and carefully remove the sticker. Part of the sticker is located just above the wiring gap. From here it is easier to bend it.

Remove the rubber plug from the middle of the fan. To do this, you can use a small screwdriver, carefully placing it behind the edge of the plug.

You will see the end of the shaft inside the cylinder in the resulting depression. Place one drop of oil into the indentation.

Just one drop is enough, no need to pour oil into the bearing.

Return the rubber stopper to its place and cover it with a sticker on top. Sometimes the sticker stops sticking. Then you can use regular electrical tape.

After the fan has returned to its place, the computer must run for several minutes before the oil completely lubricates the cooler. After some time, the computer will become quieter and stop getting too hot.

The properties of lubricants used in computer cooler fans largely determine the wear resistance of the latter. Incorrectly selected lubricant can cause noise, vibration, and unit failure. To prevent this from happening, it is important to know what and how to lubricate the cooler of a computer or laptop.

How to choose a lubricant for a cooler?

An Internet search engine produces a huge amount of information in response to the question posed in the title. However, most articles on this topic are superficial, and the arguments of users of technical forums are not supported by facts and are based only on personal experience. Meanwhile, experiments with lubricants without basic knowledge can cause damage not only to the cooling device, but also to the malfunction of expensive components of the system unit.

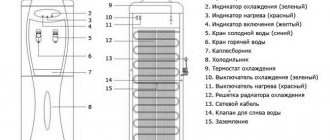

Every computer fan contains a bearing. The latter are of two types - rolling and sliding. Rolling bearings are found both closed and open. The former, unlike the latter, do not require periodic lubrication. Sliding bearings are made of special alloys and materials and contain anti-friction fillers, which means a long service life without preventive application of lubricant.

Different lubricants are used for different types of bearings. However, in fans of modern PC cooling systems the lion's share is made up of sliding units, so we will focus on them.

The correct lubricant for a given unit must meet certain criteria, these are:

- Optimum viscosity for high speeds. This requirement is satisfied by relatively thin oils, but not by thick materials.

- The presence of special dispersion additives in the lubricant (for example, Teflon) for easier starting and stopping of the bearing. During the acceleration and braking of the fan, the so-called boundary mode occurs with an intense level of wear of parts. Fillers form a film and facilitate the boundary regime.

- Absence of any negative impact (swelling, shrinkage of plastic and rubber, corrosion of metal alloys) on fan components. Many motor, transmission and industrial oils are not suitable for application to computer cooler bearings, as they have such effects.

- Increased penetrating properties. The lubricant should easily penetrate into the gaps of all surfaces of the device.

- Increased adhesion (grip). Low adhesion material will flow out of the assembly.

Types of bearings

Before you begin disassembling and lubricating, it is advisable to know the type of bearing that is used in your cooler. This affects the choice of oil and lubrication method.

The following bearings are used in fans of household and computer equipment:

- Sleeve bearing is the most common and simplest type, which consists of a bushing with a rotating shaft. The bushing is covered with anti-friction material. WD-40 is suitable for lubricating them.

- Slides with screw threads (rifle bearing, Z-Axis bearing) - have specific threads on the axle bushing that recirculate the lubricant.

- Hydrodynamic (FDB bearing) - a modernized sliding bearing, where the rotation of the shaft is carried out in a layer of liquid substance, which is held inside the sleeve due to the pressure difference created during operation

- The rolling element (ball bearing, ceramic bearing) consists of two rings (balls), rolling elements and a separator. Ceramics can be used as a material. For rolling bearings, grease (silicone) is used.

- Oil Pressure Control (SSO) - Improved fluid dynamic bearing. A distinctive feature is a large amount of liquid (lubricant). To reduce wear, the shaft is centered by a permanent magnet installed in the base.

- Self-lubricating plain bearing (LDP) is an improved plain bearing. There is IP6X dust protection and a special slot for recovered oil, which increase the service life of the fan.

- Polyoxymethylene bearing (POM Bearing) is a modernized plain bearing. To increase service life, the shaft is coated with polyoxymethylene, which has a low sliding friction coefficient.

The article will discuss the lubrication of coolers with bearings of the first and fourth types: sliding and rolling.

Which oil to choose?

Based on the above, the following oils have the best characteristics for lubricating fans:

- quite liquid;

- forming a film on the surface;

- having the effect of filling roughness and gaps.

This is a fairly large group of materials, and they definitely do not include animal and plant compounds in any proportions or variations.

The following products are most suitable for treating computer coolers:

- Low viscosity oils.

Among them are weapons-grade, transformer, machine, spindle, etc. They are distinguished by excellent penetrating ability and create a very thin film. Recommended for high-speed mechanisms with low dynamic loads. - Medium viscosity oils.

This includes engine, transmission, etc. They form a thicker film, penetrate well and fill gaps, stay on the surface longer and can cope with high loads. They have a minus - they load the mechanism.

Separately, it is worth mentioning about high-viscosity lubricants. These include solid oil, lithol, etc. They can be used, but with caution, applying a tiny amount, and only for processing powerful coolers (for example, used in power supplies).

Thick lubricating compounds do not penetrate well, but forced pressing into the gaps can help start up an almost “dead” device for some time (before purchasing a new fan). Small and microfans in laptops cannot be lubricated with such compounds.

Meanwhile, specialized stores offer a wide range of lubricants for coolers. These synthetic lubricants are completely inert and operate in a wide temperature range (from -20 to +200.300 °C). Ease of use and precise dosing are ensured by a special syringe containing oil. And in most situations, it is better to use a ready-made solution (for example, SPO-1

or

SPO-2

).

How to lubricate a cooler?

A computer can have at least two coolers installed: in the power supply and on the central processor. Cooling systems are also installed on high-performance video cards. The air environment inside the system unit can be cooled by one or two additional fans.

Typically, coolers do not require preventative lubrication; it is enough to clean (blow out) the fan and radiator. But if the device vibrates and makes a lot of noise, it either needs to be urgently changed or lubricated. But first you need to identify the problematic device.

To do this, the fans are alternately (shortly!) slowed down with a finger in the center of the impeller. Do not touch the blades as you may injure your hand. The problem node is identified using the elimination method. The last in this link is the power supply cooler, since it is usually impossible to get to it without disassembling it.

The fans of the power supply, processor and video card, as well as additional ones installed on the case, are structurally arranged and disassembled in the same way. Differences may be in mounting options and dimensions.

In some cases, the fan does not need to be removed from the radiator or unscrewed from the case. This is usually possible when the device drives the air flow away from the radiator or case, and not towards them. If the opposite situation occurs, in order to remove the assembly, you will have to refer to the description of the specific component.

As a rule, on the radiators of the central processor and video card, the fan is secured with special latches. The cooling device is screwed into the power supply and on the case. To get to the cooler in the power supply, the latter will have to be removed and disassembled.

To get to the bearing, carefully peel off the sticker (round, located on the side where the wires exit). Try not to damage it or spoil the sticky layer of glue.

Additionally, the devices are equipped with a rubber or plastic plug, which greatly facilitates the process. The cork must be carefully pryed with a sharp awl and removed.

The fan impeller is directly held in place by a small flat split washer made of plastic. It needs to be removed using an awl and a screwdriver. You need to be extremely careful - this fastener element is very fragile. Now, to remove the impeller, remove the rubber ring from the shaft.

Before lubrication, it is necessary to remove dirt and old grease from the surfaces of the assembly. To do this, use pure alcohol or special cleaners. For these purposes, you should not use acetone or other products with aggressive compounds. They can damage the plastic and rubber elements of the fan and harm the electronic components of the engine.

After the cleaner has completely evaporated, put the impeller in place and apply a small amount of lubricant (literally a drop from the needle). Twist the element by the blades to distribute the oil. The impeller should rotate freely by inertia. After manipulation, secure the ring and washer.

Wipe the top of the impeller with cleaner and apply the sticker. If the latter does not hold, use tape.

Watch the video where a home master shows how to lubricate the cooler and explains the best way to do it:

Laptops and game consoles

If your laptop or console starts to make noise, it is strongly recommended not to carry out maintenance at home. The risk of damaging something due to insufficient qualifications is very high. It is better to contact a service center, and if the warranty has already expired, then many private workshops are willing to service laptops such as ASUS, HP, Acer Aspire and Lenovo; you can also contact them to service PS3, PS4 or Xbox consoles.

The magazine “Miss Clean” reminds that absolute silence during computer operation can only be achieved by replacing all cooling elements with massive radiators, which are ineffective in modern systems.

Also, do not forget that hard drives make a lot of noise when operating, and if silence is a priority, then they should be replaced with SSD drives. And in order to reduce noise, it is recommended to use closed cases with noise-absorbing inserts and carry out maintenance on the main cooler at least a couple of times a year, clean it of dust and lint, and lubricate it. The procedure will significantly reduce the load on other cooling devices, and you will have to change the thermal paste somewhat less frequently.

How often should you lubricate your computer fan?

Initially, the cooler bearings contain a sufficient amount of factory lubricant; it is structurally protected from the influence of negative external factors and does not require preventive measures to replace or add a lubricant. However, severe operating conditions, especially continuous operation and high temperatures, reduce the warranty period of the lubricant.

For this reason, fan elements in computers and laptops are processed after the fact, when noise or vibration generated by the cooler appears. However, the problem is often solved by replacing the device with a new one.

The most suitable for lubricating PC fan bearings are synthetic machine oils, for example, automobile oil or a composition for lubricating sewing machines. For these purposes, you should not use thick lubricants, products with a high content of graphite, and aggressive compounds such as WD-40. Lubricating coolers with animal fat or vegetable oil is strictly contraindicated.

What exactly should I clean from dust?

1. Overheating of the processor The computer chip has its own cooling system, which includes a cooler equipped with a radiator. The fan tries to prevent overheating, but accumulated microparticles interfere with normal air circulation. It is better to clean the processor from dust once every six months than to face sudden shutdowns of the computer due to overheating or other troubles.

For inexperienced users, the best option is express cleaning. It will not be possible to completely rid the system unit of dust, but the risk of breaking something or screwing it on incorrectly is minimized. Disassembly in this case consists of 5 stages:

Before cleaning the motherboard, free it from the wires and remove the RAM.

If you contact the service, premium cleaning can cost twice as much as basic cleaning.

To prepare graphite lubricant, you need to take a few drops of synthetic machine oil and add graphite powder to it. Mix thoroughly until smooth. The result should be a graphite lubricant with a thick consistency.

More homemade products: How to connect two batteries to increase capacity - ideas with photos

Graphite itself is a lubricant because its crystals are scaly and densely cover the surface with a thin layer. The oil performs rather a graphite binding function. Applying self-made graphite grease to the wearing surfaces of the bearing, in combination with synthetic machine oil and graphite, will ensure long service life of the cooler without replacement or maintenance.

Graphite for preparing cooler lubricant can be obtained by grinding off the lead of a simple pencil or brushes from a commutator motor on fine sandpaper. Some brushes are made from a mixture of graphite and carbon. Therefore, if you are not sure that the brush is graphite, then it is better not to use such a brush. Of course, it is best to use industrial-made graphite for lubricant.