Shelf life of chicken according to GOST and SanPiN standards

According to these standards, chicken carcasses are divided into 4 categories:

- cooled (temperature up to 25 degrees);

- chilled (from -2 to +4);

- frozen (from -12 degrees and below);

- deep frozen (-18 degrees).

How long does chicken last in the refrigerator?:

| Temperature | Whole carcasses | Carcass parts |

| -2 to +2 | 5 days | 2 days |

| -12 | 8 months | 3 months |

| -18 | 12 months | 3 months |

| -25 | 14 months | — |

Note to the table: time is counted from the moment the chicken is slaughtered. These deadlines are maximum. In practice they can be much smaller.

GOST and SanPiN standards also regulate the shelf life of semi-finished products, offal and ready-made dishes. At temperatures from +2 to +6 the timing is as follows:

Storing meat, offal and poultry

Category: Meat and meat products

Cooling and storing meat, offal and poultry in a refrigerated state is the most advanced method of preserving them.

Cooling significantly delays enzymatic and microbiological processes in meat and offal. During the period of mass slaughter of livestock, in addition to chilled meat, cooled meat is also supplied to trade. However, cooled meat in the rigor mortis stage is less suitable for cooking than chilled meat.

Meat on refrigerators

cooled in special chambers at a temperature of about 0 ° C; lower initial temperatures are also used for stepwise cooling. However, very rapid cooling leads to “cold” muscle contraction and irreversible changes, with muscle tissue acquiring a hard consistency. The reason for the “cold” contraction is the inhibition of biochemical processes at a temperature of about 10 °C. The quality of meat can be improved by electrical stimulation - the effect of electric current on steamed carcasses or parts of carcasses. Finish cooling at a temperature in the thickness of the meat from X) to 4 °C.

When the meat is cooled, the muscle tissue contracts somewhat and loses its elasticity, the surface becomes brighter due to the transition of myoglobin to oxymyoglobin; in addition, it happens

shrinkage of meat due to evaporation of moisture. Weight loss, depending on the cooling methods and type of meat, is allowed from 0.82 to 3.56%. Thus, for beef in half-carcasses and quarters of fatness category I, the shrinkage rate is no more than 1.60%, for category II - 1.75, for lean - 2.10%.

Properly chilled meat has a dry crust; The color of chilled beef is bright red, pork is pale pink, and lamb is dark red. Lamb and beef have a specific smell, pork is almost odorless. The consistency of all types of meat is elastic; the muscles do not release meat juice when pressed lightly. However, the quality of meat improves only after it is aged. The technological properties of meat and the quality of meat products prepared from this meat depend, other things being equal, on the duration and temperature of its storage. Technological properties mean the degree of suitability of meat for refrigeration, processing into meat products and culinary use. Meat used immediately after the slaughter of an animal is considered less suitable for culinary processing. Unripened meat after heat treatment is tough, the broth from it is not very concentrated. When aging carcasses, the meat matures, which helps improve its quality, both as a semi-finished product for cooking and as a raw material for the production of meat products.

Meat ripening -

a process that is caused by enzymes, as a result of which the meat softens and substances are formed in it that improve the taste and smell of the finished product. Maturation is caused by numerous biochemical and colloidal changes in the meat of slaughtered animals.

During the life of an animal, meat compounds are in a state of decay, but balanced by their synthesis. After the slaughter of an animal, the nature and direction of these processes change due to the cessation of the supply of oxygen and nutrients dissolved in the blood to the cells. Synthesis fades and autolysis begins to dominate. The general direction of autolysis is the simplification of complex compounds and the accumulation of a number of under-oxidized products.

The entire complex of post-mortem changes can be divided into three periods. The first period lasts about 3 hours - before the onset of rigor mortis and ends after 1-2 days of carcass storage; The muscles are in a state of increasing rigor. The third period is characterized by the destruction of rigor and subsequent softening of the meat.

In the first period, muscle tissue is soft and elastic. The pH value of meat is close to neutral. Meat contains a significant amount of glycogen, creatine phosphate and ATP. Individual proteins are extracted with water or saline solutions from muscle tissue, significant digestibility of collagen and a high content of bound water are observed. Nucleotide breakdown products are contained in minimal quantities.

Meat in the steamed state is quite suitable for making boiled sausages and freezing.

The second period is characterized by the development of rigor mortis. Muscles lose elasticity, thicken and harden. The intensity of rigor rigor depends on the temperature, species, age, fatness and condition of the animal before slaughter. The rigidity of meat and its resistance to cutting force increase approximately 2 times. The content of bound water and the ability of meat to hydrate decrease, and its resistance to the action of proteolytic enzymes increases. The process of rigor mortis is the result of numerous changes in meat systems. During this period, anaerobic breakdown of glycogen occurs with the formation of lactic acid, reducing polysaccharides and glucose. The storage stability of meat, its water-holding capacity and the activity of tissue enzymes depend on the level of lactic acid accumulation. The increase in rigor mortis is due to the formation of the actomyosin complex as ATP levels decrease. Decreased protein hydration affects meat toughness as the pH of muscle tissue approaches the isoelectric pH of the underlying proteins. The greatest hardness of meat is observed at pH = 5.5. By moving the pH to either side of the isoelectric point of proteins, the tenderness of the meat increases. A pH shift leads to wedging of the polypeptide chains of individual proteins, an increase in hydrophilic centers and, accordingly, an increase in the moisture absorption capacity of meat.

The third period is characterized by softening of meat due to the breakdown of actomyosin in the presence of easily hydrolyzed phosphorus. Autolytic processes continue due to the action of proteolytic enzymes. Accumulation of free amino acids, breakdown of nucleotides, dissolution of mucopolysaccharides, and increased digestibility of collagen are observed. At the same time, the taste properties of meat and broth are improved. Aromatic and flavoring substances, as a rule, are of a low-molecular nature. These substances include a very large group of carbonyl compounds and sulfur-containing substances. Among them are amino acids, low molecular weight fatty acids, aldehydes, phenols, alcohols, esters, and from nucleotides - adenyl, guanyl, cytidylic, inosinic and uridylic acids. Nitrogen-containing extractive substances include creatine, creatinine, anserine, carnosine, carnitine.

When different muscles or their parts are cooked by heat, the resulting taste and aroma are not the same in intensity. Soft muscles, which work little during the life of the animal, produce a broth that is not tasty and aromatic enough compared to tougher meat.

Beef ripening ends at a temperature of 0-4 °C after 10-12 days of aging meat carcasses. The ripening period for other types of meat is shorter, and for meat of different types of poultry it is limited - 1-6 days.

Maturing meat is a long process, and a number of methods are used to speed it up. Physical and biochemical methods have been developed using enzymes of plant, animal and microbial origin.

Physical methods - electrical stimulation, exposure to elevated temperature with simultaneous UV irradiation. In the meat industry, in the production of smoked meats, various deforming effects are used - massaging or tumbling cuts of meat. A method for treating meat with ultrasound has been proposed, under the influence of which cells are destroyed and lysosomal enzymes are released.

Biochemical methods include methods based on the action of proteolytic enzymes of plant and microbial origin. The following enzymes are used in the meat industry: papain, contained in the leaves of the melon tree; ficin - in fig leaves; bromelain - in pineapple leaves. The optimal activity of these enzymes occurs at a temperature of about 50 °C.

The source of enzymes of microbial origin are bacteria, actinomycetes, yeast and mold. There are more than 40 types of enzyme preparations made on the basis of these enzymes. The use of the drug terrizin, isolated from the microbe terricol, is allowed. To soften meat, 15 g of this drug per 1 ton of meat is enough.

Physiological methods for accelerating maturation involve administering active drugs to animals 2-3 hours before slaughter. Adrenaline, pyrocatechin and a number of other physiologically active compounds, collectively called “demotins,” are used as such drugs. These drugs accelerate the breakdown of glycogen, reduce lactic acid levels, inhibit the breakdown of ATP and prevent the formation of the actomyosin complex.

The use of various methods to accelerate ripening makes it possible to use almost all tough meat for the preparation of portioned semi-finished products with a fairly acceptable consistency.

Chilled meat is sent mainly to retail trade, and is also used in the production of individual sausages and minced semi-finished products.

During storage

chilled meat must be kept at a constant temperature. Fluctuations in ambient temperature lead to deterioration in quality, increased losses and a significant reduction in the storage time of meat due to moisture condensation on its surface. Even a small change in air temperature at high relative humidity is enough to reach the dew point and moisten the surface of the meat. To reduce losses due to moisture evaporation, reduce air circulation. However, low circulation leads to stagnation of air, mucus and molding of meat, so they create an intensity of circulation that helps slow down the development of microbes.

It is recommended to store chilled meat in refrigerators at a temperature of 0 to -1.5 ° C, a relative air humidity of 85-90% and air circulation. 0.2-0.3 m/s. Under these conditions

The storage duration, taking into account transportation time, is: beef - 10-16 days, pork and lamb - 7-14 days.

Frozen (supercooled) meat can be stored at a temperature of -2 °C ±0.5 °C for up to 17 days.

High-quality cuts in reusable containers are allowed to be stored at enterprises at temperatures from 0.5 to -1.5 ° C for no more than 7 days, and those packed in polymer film under vacuum - up to 15 days.

Loss of meat mass depends not only on temperature and humidity conditions, but also on the type of meat, its fatness and specific surface area.

To increase the shelf life of chilled meat, which is relatively short, methods have been developed for storing it in a frozen state, in an atmosphere with the addition of carbon dioxide, using ultraviolet rays, antibiotics and penetrating radiation. However, they have not received widespread industrial use.

Since the shelf life of chilled meat is limited, it is frozen. Long-term storage of frozen meat is possible at temperatures below -10 °C.

Freeze chilled or fresh meat. The production and storage of frozen meat is associated with additional costs for freezing and maintaining the necessary storage conditions. In addition, meat loss is inevitable during freezing and storage. Frozen meat is inferior in quality to chilled meat. During storage, the organoleptic characteristics and nutritional value of frozen meat deteriorate due to the partial loss of vitamins and changes in fat. However, freezing still remains the main method of preserving meat for long-term storage.

Meat is frozen in freezers and freezers mainly at temperatures from -18 to -25 °C, but lower temperatures are also used. When meat is frozen, the bulk of the water and tissue fluid turns into a crystalline state, so the muscle tissue becomes hard and the fat acquires a crumbly consistency. Microbiological processes in frozen meat stop, and enzymatic processes slow down sharply.

The quality of frozen meat and the reversibility of the freezing process are influenced by both the initial state of the meat—the depth of the ripening process—and the speed of freezing. Increasing the freezing speed has a positive effect on the quality of defrosted meat.

Store

frozen meat tightly stacked in refrigeration chambers. During storage, weight loss occurs and the quality of meat changes. The surface of the muscle tissue gradually dehydrates and becomes porous. Recrystallization, associated with the growth of some crystals at the expense of others, leads to deformation and partial destruction of muscle fibers. Fat that changes color goes rancid and gives the meat an unpleasant taste. The state of proteins changes, the process of their aging occurs,

which leads to a decrease in the water-holding capacity of thawed meat. Fat-soluble vitamins are destroyed, except for vitamin A. Water-soluble vitamins are less susceptible to destruction, with the exception of vitamins contained in pulp by-products.

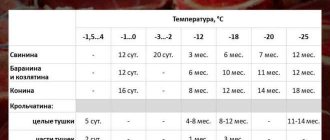

The shelf life of frozen meat depends on the temperature, type of meat and its fatness. At a temperature of -18 °C and a relative air humidity of 95-98%, beef can be stored for up to 12 months, lamb - up to 10, pork with skin - up to 8, without skin - up to 6 and offal - no more than 4 months. At a temperature of -25 °C, the shelf life of beef increases to 18 months, pork and lamb - to 12 months.

In order to better preserve frozen meat, it is necessary to minimize the evaporation of moisture from its surface. Meat shrinkage decreases with increasing relative humidity and decreasing air circulation. To reduce the shrinkage of frozen meat during long-term storage, use ice screens or cover the stack of meat with a cloth and freeze a layer of ice glaze on it. In the summer, as a result of increased heat transfer through the walls of the refrigerator chambers, shrinkage can increase significantly.

In stores and bases where the thermal regime changes, the shelf life of chilled and frozen meat is significantly reduced. The shelf life of chilled and frozen meat at temperatures from 0 to 6 °C is up to 3 days, and beef cuts in containers are no more than 48 hours. At a temperature of about 0 °C, frozen meat can be stored for up to 5 days. At a temperature not exceeding 8 °C, chilled and frozen meat is stored for no more than 2 days.

Packaged chilled meat at temperatures from 0 to 6 °C can be stored for no more than 36 hours.

By-products

cooled in special chambers on multi-tiered racks, which are transported along overhead tracks from the processing workshop. Lay out the offal on metal baking sheets in a 10 cm layer. Place the kidneys, heart, brains, and tongues in one row. Shrinkage of by-products during cooling reaches up to 1.63%. However, it is not recommended to store offal for a long time in a refrigerated state, since they spoil faster than meat.

Refrigerated offal products are stored at a temperature of about 0 °C for up to 3 days, from 0 to 6 °C for 36 hours, up to 8 °C for 12 hours. Frozen offal products are stored at the same temperature for up to 3 days, respectively. 48

and 24 hours

Poultry and rabbit carcasses

stored both refrigerated and frozen.

Chilled poultry is stored in stacked boxes or on racks. Shelf life at temperatures from 0 to 4 °C and relative humidity 80-85% is up to 4-5 days. When storing chilled poultry and rabbits, it is necessary to carefully monitor compliance with storage conditions and, if a slight foreign odor appears or a change in surface color, immediately sort the carcasses. The quality of poultry deteriorates during storage, and due to loss of moisture, their weight decreases.

Frozen poultry is stored in boxes stacked tightly. The permissible shelf life depends on storage conditions and the type of bird. The maximum shelf life at temperatures from -12 to -15 °C and 85-90% relative humidity for geese and ducks is 7 days, for chickens, turkeys and guinea fowl - 10 days; at a temperature of -25 °C and below - 12 and 14 months, respectively.

Frozen rabbit carcasses are stored at a temperature no higher than -9 ° C and a relative air humidity of 80-90% for no more than 6 months.

During storage, the appearance of the carcasses changes significantly: the skin becomes dry and brittle, and yellow stripes or spots appear in places where the carcasses touch. When stored for a long time, fat goes rancid and its color and taste change. The fat of geese and ducks deteriorates especially quickly.

In the store, the shelf life of poultry carcasses of all types at temperatures from 0 to 6 ° C is up to 3 days; at a temperature not higher than 8 ° C, chilled poultry is stored for 24 hours, and frozen poultry is stored for up to 2 days.

In distribution refrigerators and retail establishments, during the storage and movement of meat and offal, their natural loss occurs due to the evaporation of moisture and the leakage of tissue fluid. To account for these losses in trade, natural loss rates are used.

These standards are established depending on the shelf life, period of year, geographical area, packaging, type and thermal state of meat and offal.

At retail trade bases and warehouses, depending on the type of meat, shelf life and geographic area, natural loss is allowed from 0.03 to 0.5%.

In the chambers of distribution refrigerators, natural loss is allowed from 0.05 to 0.40%, depending on the type and fatness of meat, geographical area, time of year, capacity and number of floors of the chambers.

Chilled meat is stored in refrigerated chambers in a suspended state. Carcasses, half-carcases, and quarters should not come into contact with walls or each other; there should be free access of air to the meat.

Chilled meat is stored at a temperature of 0°C, relative humidity 80% for no more than three days.

Frozen meat is stored on pallets in stacks at a temperature of -3°C and a relative humidity of 80-90% for up to three days.

How to choose fresh poultry

How long does raw chicken last in the refrigerator ? Agree that the answer to this question will not make sense if you initially bought a stale product.

We recommend reading: How long does homemade mayonnaise last?

Bad chicken won't just ruin your meal, it can literally cost you your health. Eating expired meat can cause severe food poisoning. Getting rid of its consequences will be long and expensive.

There are two things that tell you that a chicken needs to be thrown away:

- bad smell;

- slime.

Fresh meat should not have any foreign odors. A rotten, fungal smell indicates that the meat should be discarded.

Mucus also indicates spoilage of meat. It may not smell at all - unscrupulous sellers treat the meat with special solutions for this purpose.

Important: do not confuse mucus with too wet meat. Manufacturers deliberately increase the humidity of their products and sell you water at the price of meat. They can also wash the chicken with special substances so that it can be stored longer.

The color of the chicken has virtually no effect on anything. Pale chicken is no worse in nutritional properties than yellow chicken.

Benefits of freezing food

In supermarkets and convenience stores you can buy a variety of frozen semi-finished products with the inscription “shock freezing” on the packaging. This concept means that the product is subjected to very rapid freezing at a very low temperature.

According to the standard, the process of freezing food products occurs in 3 stages:

- Cooling to 0.

- Freeze to -5°C.

- Deep frozen to -18°C.

Semi-finished products frozen by shock and conventional methods are stored in the same freezers in supermarkets. There are several advantages of the shock freezing method to give preference to:

- production time is reduced by at least 3 times;

- reduction of product losses by 2–3 times;

- production areas are reduced by up to 2 times, and personnel by up to 30%;

- production payback decreases by 15–20%.

A more accurate idea is given by the numbers: regular freezing of dumplings occurs in 2.5 hours, and shock freezing - in just 20 minutes.

How long does chicken last and how to store it?

How long does chilled chicken last ? According to the Sanitary Rules and Standards mentioned above, the shelf life of chilled chicken is 5 days from the date of slaughter. If there is no information when the chicken was slaughtered (for example, you bought the carcass secondhand at the market), start cooking immediately.

Fresh meat “ripens” for 2-3 hours. After this it goes into the refrigerator.

Important detail: the meat must be in a bag (paper). Make a small hole in the bag for air circulation.

How long does frozen chicken last ? From 5 to 7 months after placing the carcass in the freezer. The meat must be in a bag (paper).

How long can you store defrosted chicken in the refrigerator ? Exactly half a day. Thawed meat is no longer frozen. But you can do it differently: freeze the prepared dish.

Storage conditions

To ensure that meat does not lose its taste and nutritional qualities, it is very important not only to choose a fresh product, but also to strictly observe storage conditions. Apart from the preparation of semi-finished products - smoking, drying, salting, drying meat, there are two options left - cooling or freezing.

To begin with, it is important to evaluate the quality when purchasing. First of all, analyze the appearance. If it is a whole carcass, the skin should not be damaged. The presence of wounds, scratches, and traces of blood should alert the buyer. It should also be dry and clean - sticky skin can be a sign of staleness or disease.

How long can cooked chicken last in the refrigerator?

Cooked chicken can be stored for a maximum of 3 months. But we recommend freezing food as a last resort - if you eat such a product, you will not get any pleasure.

Store the finished dish in the pan in which it was prepared. If you take away some of the meat, be sure to boil the rest.

How long does boiled chicken breast last in the refrigerator ? Maximum – 48 hours. You can store meat without broth.

How long does frozen cooked chicken last in the freezer ? The deadline is 90 days. Of course, the freezer cannot be defrosted.

Chilled fried chicken can be stored in the refrigerator for up to 12 hours. You can freeze it too. But there is a drawback - the meat will be tough.

How long can smoked chicken last in the refrigerator ? Store-bought chicken can be stored for up to a day. You can find a more detailed answer to this question in our other article.

Grilled chicken is eaten hot. If necessary, you can store leftovers in the refrigerator, but the meat should be eaten after 12 hours.

Marinated chicken can be stored at room temperature for up to 2 days. In the cold for up to 5 days. These terms are valid when using a classic marinade consisting of water, salt, sugar, vinegar and spices. If you made a different marinade, the period is reduced to 12 hours.

Important: after removing the chicken from the marinade, eat it a day before.

Types of semi-finished products and their popularity

A semi-finished product is a product prepared for consumption, but not yet undergone heat treatment; it must be prepared in any convenient way (fry, bake). There are several varieties:

- Culinary products.

- Frozen.

- Ready meals.

Perhaps one of the most popular is culinary. These include steaks, chilled kebab, goulash, beefsteaks, chicken breasts, cutlets and the like. They have already been processed, they just need to be cooked.

Frozen foods include pancakes, pizza, vegetables and fruits. Highly prepared foods—those that have been processed or already cooked—are frozen.

Ready-made meals are also very popular. These are salads - from “Olivier” to “Vitaminny”, a variety of meat products - “Kiev” cutlets or French meat. Such semi-finished products are already ready and can be eaten immediately or after cooking.

The rules for processing each product, as well as the shelf life of freshly prepared chilled and frozen semi-finished products are indicated on the packaging. Therefore, before purchasing any product, you should look at the production date and shelf life of semi-finished meat products.

Freezing quality requirements

Mostly, semi-finished products with a high degree of readiness are frozen, that is, those that are not only processed, but also cooked (for example, fried). These are pancakes, seafood, pizza, pies, the same cutlets, vegetables and fruits.

How should finished products of semi-finished products with a high degree of readiness for storage be prepared?

There is a general rule that applies to all frozen semi-finished products, ready-made culinary products, and gourmet snacks without exception: pack the product in cellophane or other film, use cardboard boxes.

Under these conditions, good quality of the product can be guaranteed on average for at least six months from the date of preparation.

Storing dough products

There are the following categories of such products:

- Dough that has been frozen at the manufacturer's factory. It can be of various types, including puff pastry or curd.

- Stores sometimes have their own cookeries or bakeries. The dough they make is offered frozen to customers.

- Some products contain dough parts. Examples of such products are dumplings and dumplings. They are usually blast frozen before sale.

For refrigerated (t from 0°C to -6°C) dough products, the shelf life is no more than 72 hours.

At a temperature of -18°C, frozen products can be stored longer - for 2 months.

If your refrigerator can provide a temperature of -24°C, then the shelf life can be up to 9 months.

The specified shelf life of semi-finished products is observed in most cases. Sometimes it happens that the manufacturer claims significantly longer terms. For example, some dumpling manufacturers guarantee storage for 6 months. In such situations, it is necessary to carefully study the composition of the product. Usually, this is due to the addition of a large number of preservatives, which can be harmful to your health.